Method for removing acid gases in cracked gas

A technology of acid gas and cracked gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the present invention, the following examples are provided, but the present invention is not limited to the examples.

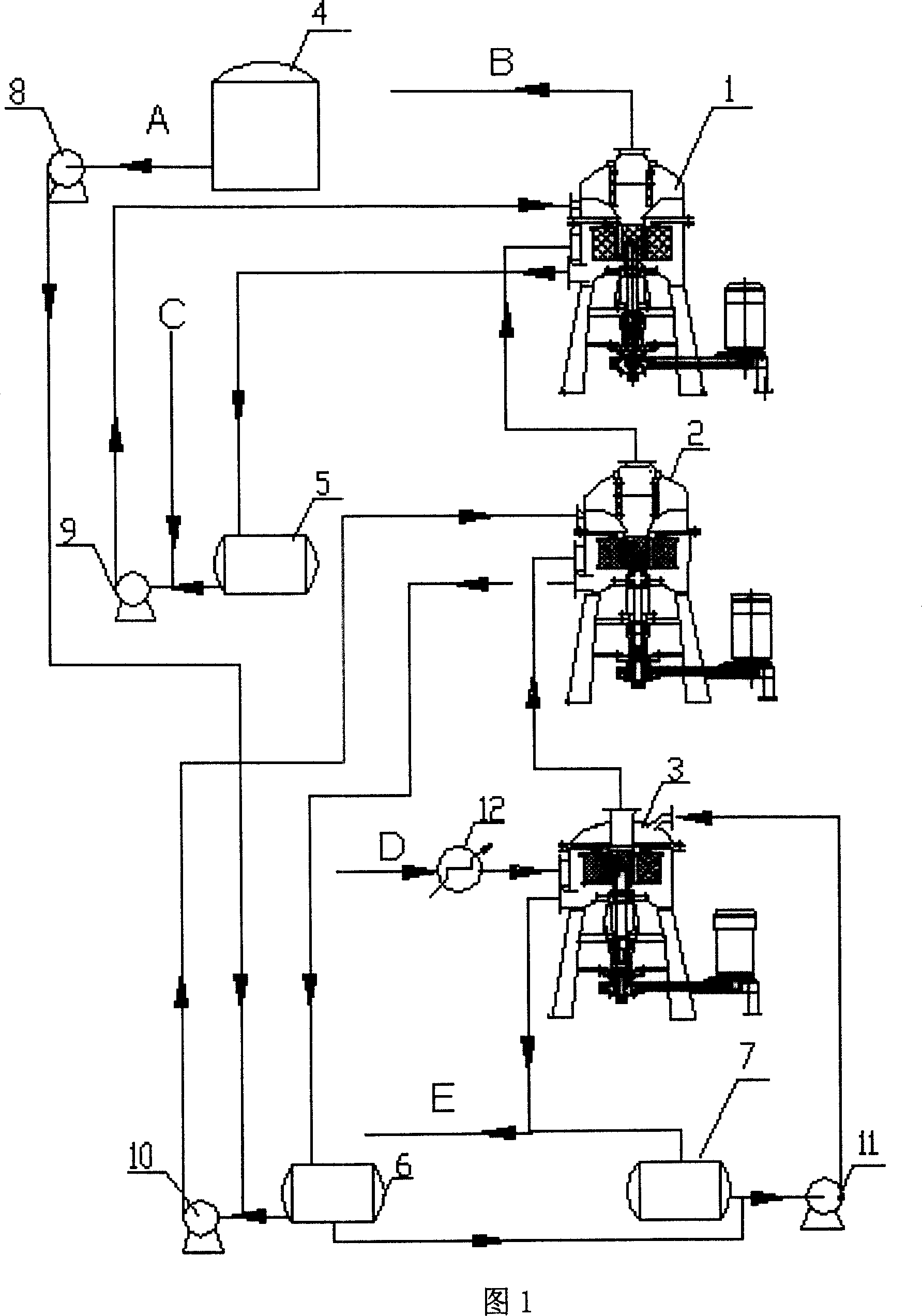

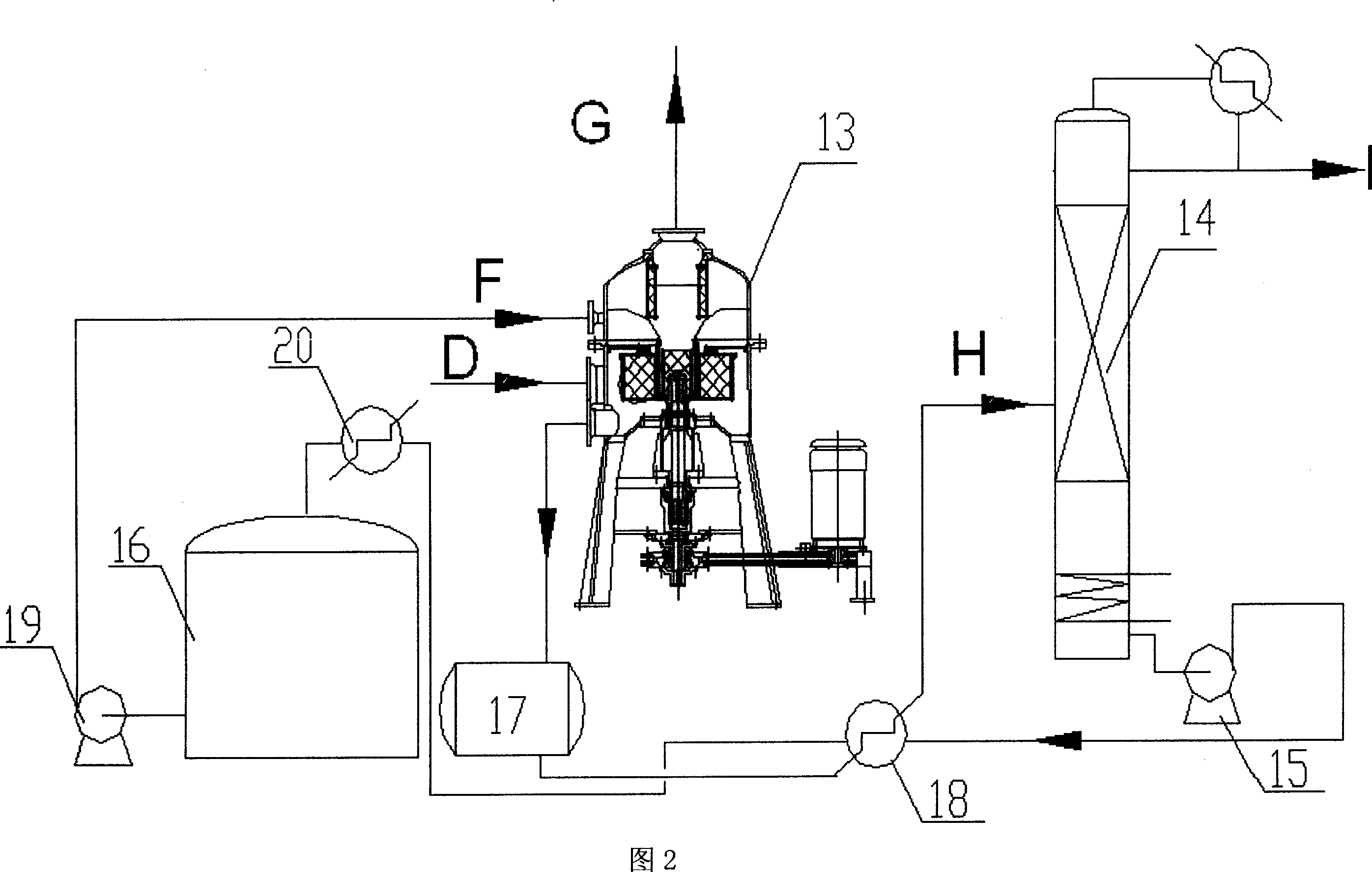

[0054] Below in conjunction with the alkaline cleaning section of the ethylene process with an annual output of 800,000 tons, the process of using the absorption tower and the high-gravity rotating bed for alkaline cleaning is compared to illustrate the effect of the present invention.

[0055] Annual output of 800,000 tons of ethylene process, flow rate of cracked gas: 296.18 tons / hour, pressure 1698KPa, temperature 46°C, composition of cracked gas is shown in Table 1. The gas-liquid phase load of each section is shown in Table 2. After treatment, the total content of carbon dioxide and hydrogen sulfide in the cracked gas is less than 1ppm.

[0056] Table 1 cracked gas composition (unit: mol%)

[0057] h 2 o

H 2

CO

CO 2

h 2 S

CH 4

C 2

C 3

C 4

C 5 above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com