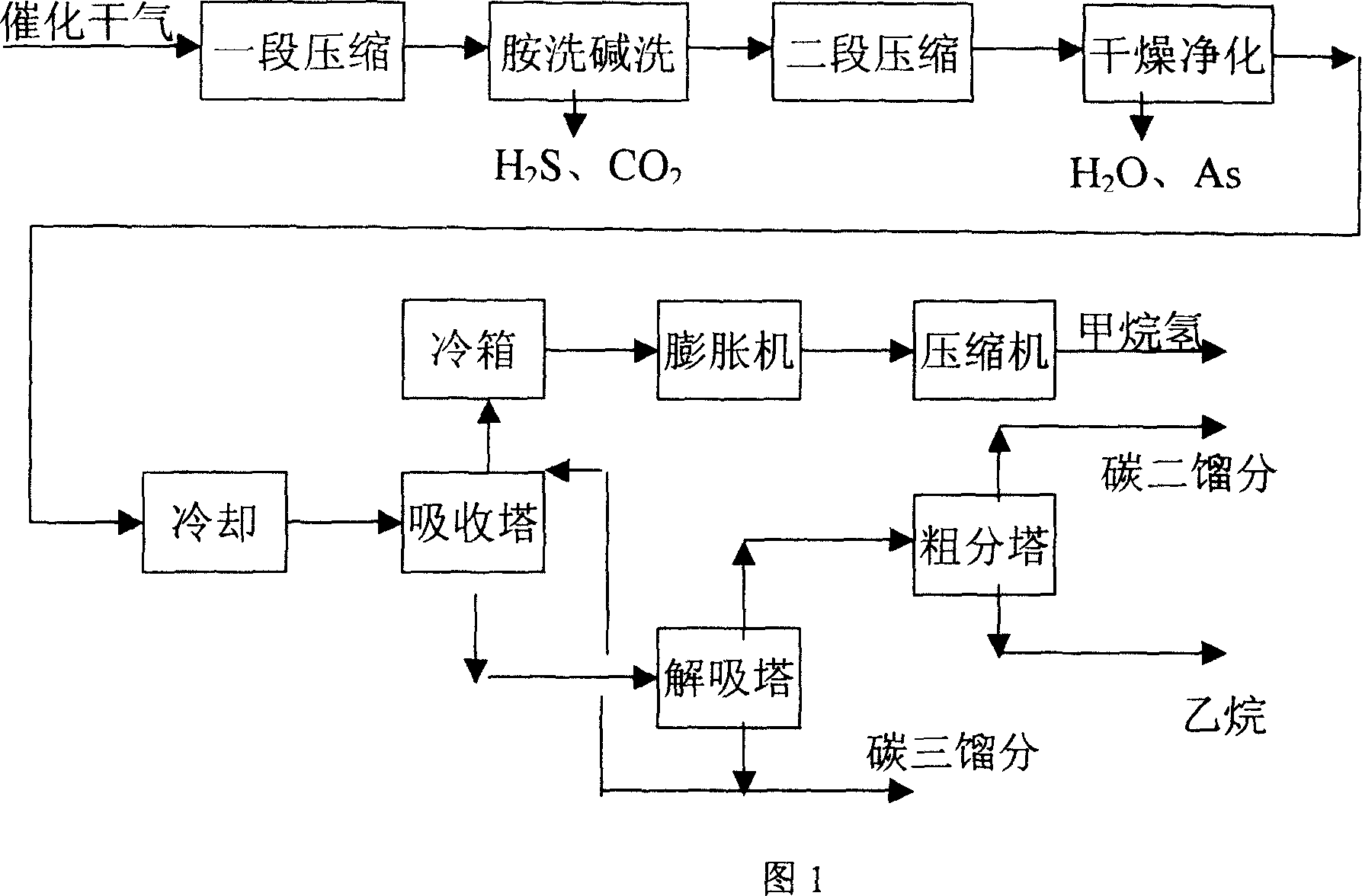

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

A cold oil absorption and refinery technology, which is applied in the processing of gas mixtures, hydrocarbon oil treatment, organic chemistry, etc., can solve the problems of large investment and high energy consumption, and achieve the effect of low investment, reasonable process and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The catalytic dry gas composition of a refinery is shown below.

[0047] Composition Volume % NM 3 / hr

[0048] H2 18.06 5418

[0049] N2 14.52 4366

[0050] O2 0.53 159

[0051] CO2 1.76 528

[0052] CH4 32.00 9600

[0053] C2H4 16.34 4902

[0054] C2H6 14.53 4359

[0055] C3 1.70 510

[0056] C4 0.36 108

[0057] C5 0.20 60

[0058] H2O 0.02 6

[0059] Total 100.00 30000

[0060] The above-mentioned catalytic dry gas is separated by adopting the intercooler oil absorption method of the present invention to separate the refinery catalytic dry gas process. The specific process is:

[0061] The catalytic dry gas from the catalytic cracking unit of the refinery has a pressure of 0.7MPa. After two stages of compression, the pressure is increased to 3.5MPa. The acid gas is removed by alkali washing between the stages of the compressor. The pressurized dry gas is dried and then gradually cooled to -35°C before being sent into the absorption tower. The theoreti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com