Autothermal reformer-reforming exchanger arrangement for hydrogen production

a technology of hydrogen exchanger and reformer, which is applied in the direction of gaseous mixture working up, electrochemical generator, energy input, etc., can solve the problems of plot area requirements, capital costs, operating difficulties, etc., and achieves reduced energy requirements, reduced capital costs, and greater ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

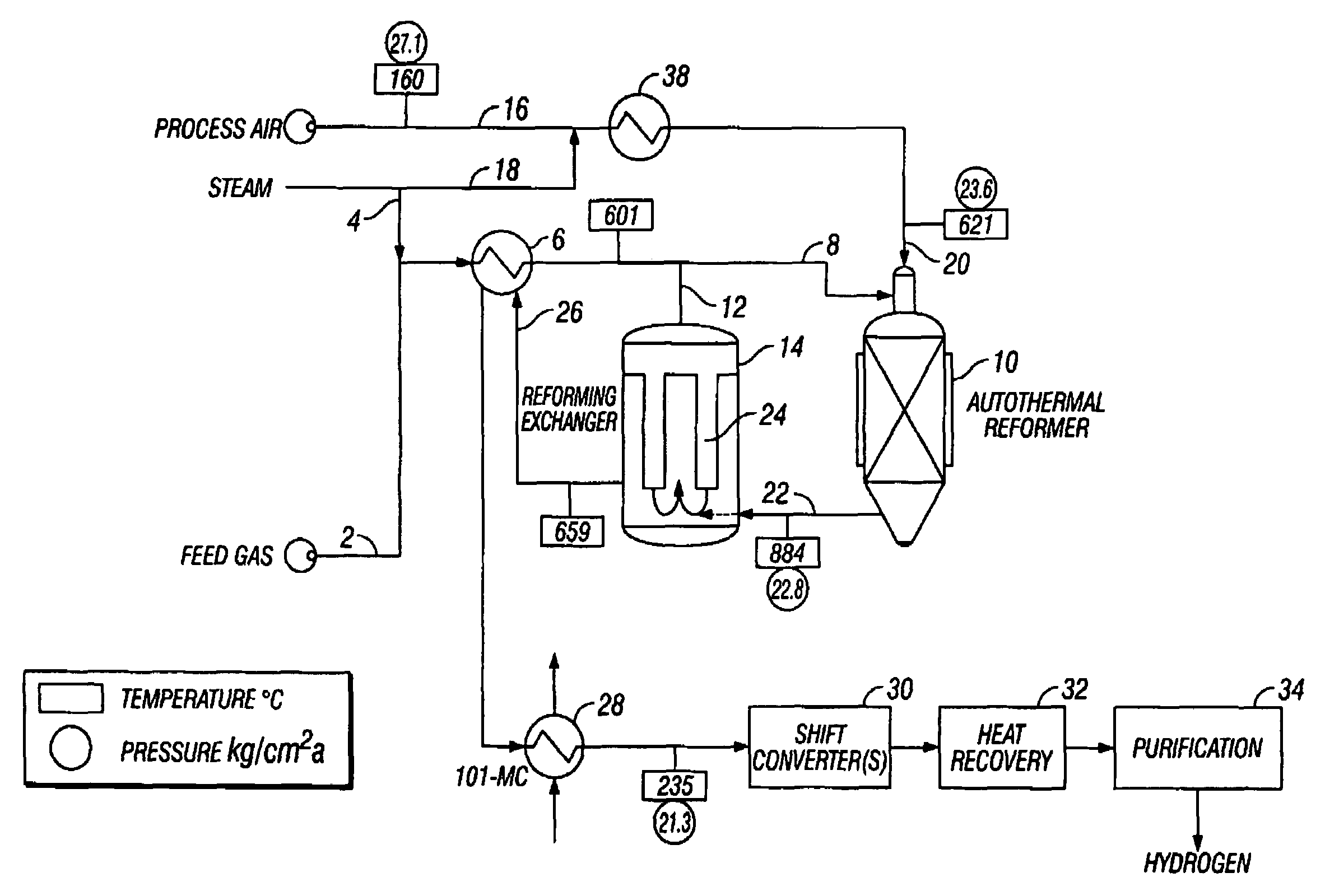

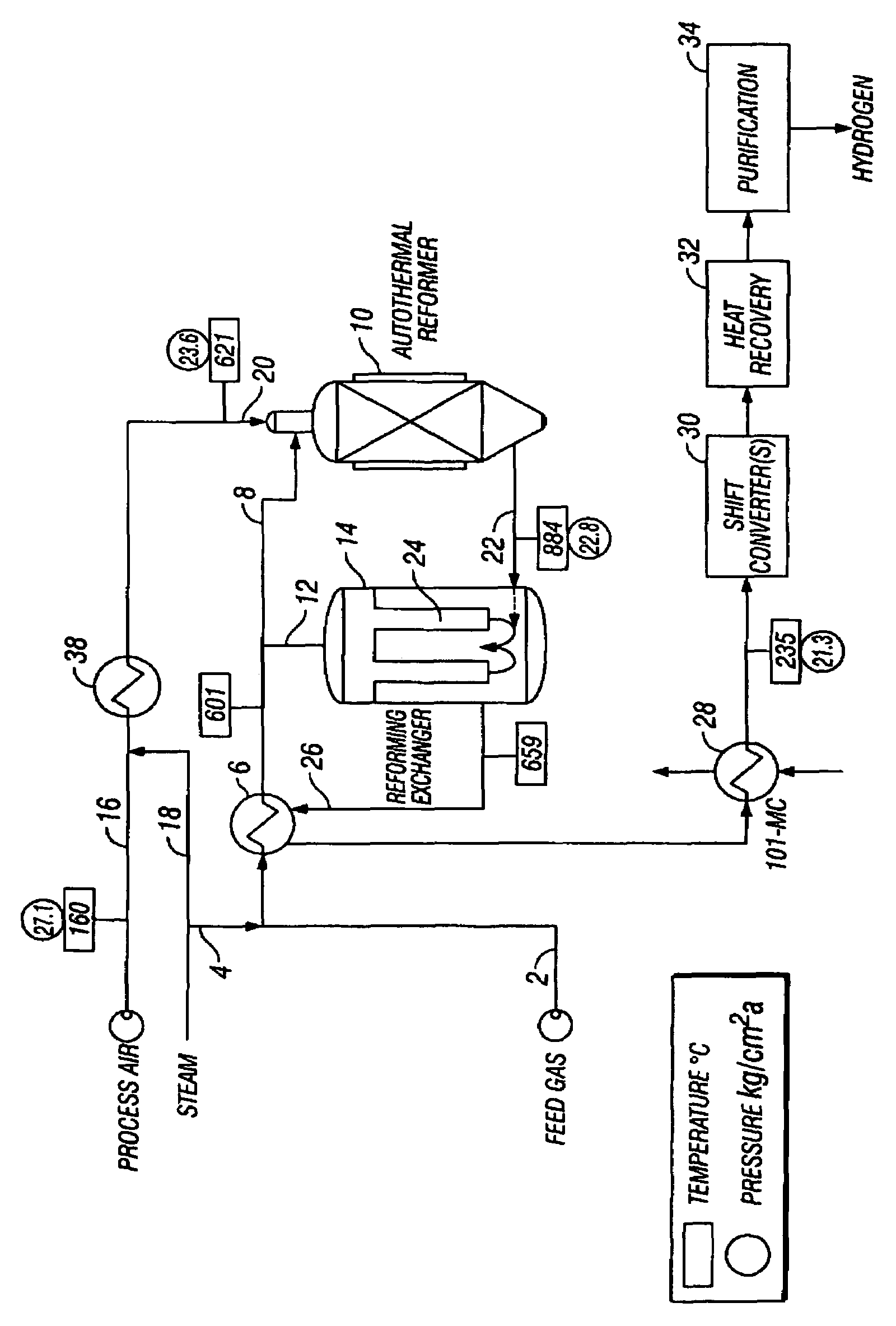

[0011]One embodiment of a process according to the present invention has the general configuration shown in FIGURE. Desulfurized natural gas or other hydrocarbon supplied from line 2 is mixed with process steam from line 4 and the mixture is preheated in a feed preheat exchanger 6. The steam to carbon ratio of the mixture is desirably from 2.0 to 4.0, e.g. about 3. A first portion of the preheated steam-hydrocarbon mixture is fed via line 8 to the burner in autothermal reformer (ATR) 10, and a second portion is supplied via line 12 to the tube-side inlet of reforming exchanger 14. If desired, additional steam can be added via line 36 to line 8.

[0012]Air is supplied via line 16 and mixed with steam from line 18, and the steam-air mixture is preheated in preheater 38, e.g. to a temperature from 200° C. to 650° C., and sent to the burner via line 20, taking due care to maintain the flame temperature in the burner below 1500° C. The air is desirably excess air, by which is meant that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com