Refinery mixed dry gas recovery system and recovery method

A refinery mixed dry gas and recovery system technology, applied in chemical instruments and methods, gas mixture processing, hydrocarbons, etc., can solve the problems of limited process applicability, low recovery rate, large investment, etc., to avoid Adverse effects, strong applicability, and the effect of less total dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

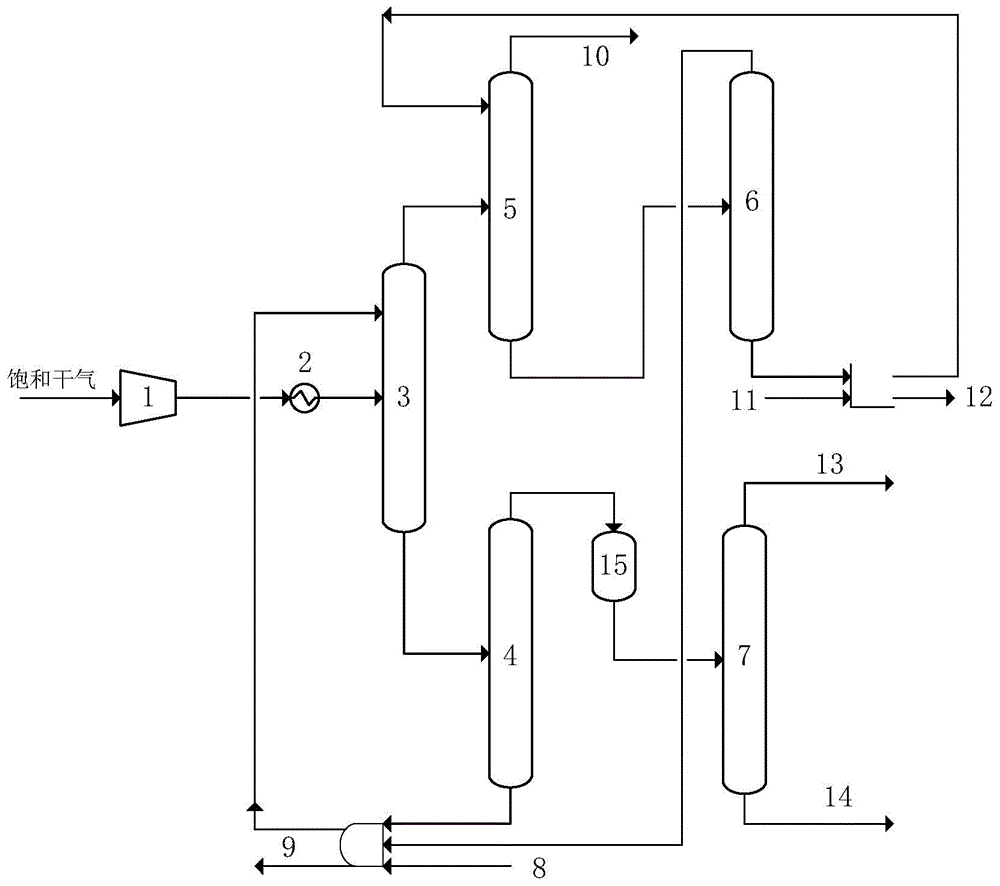

[0063] Such as figure 1 As shown, a refinery mixed dry gas recovery system includes: an absorption tower, a desorption tower, a purification device, a rough fractionation tower, a gasoline absorption tower and a gasoline desorption tower;

[0064] The compressor is connected to the heat exchanger and then connected to the absorption tower. The top of the absorption tower is connected to the gasoline absorption tower, and the bottom of the absorption tower is connected to the desorption tower; The top is connected to the upper part of the absorption tower, and the bottom of the gasoline desorption tower is connected to the upper part of the gasoline absorption tower. A reboiler is installed at the bottom of the absorption tower.

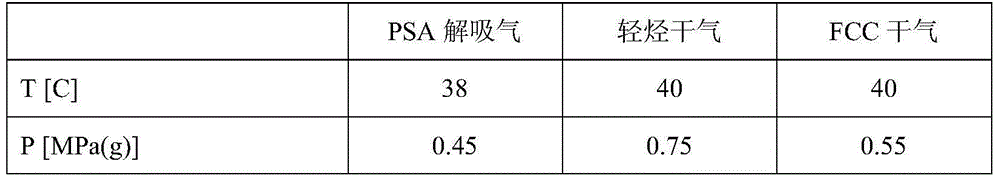

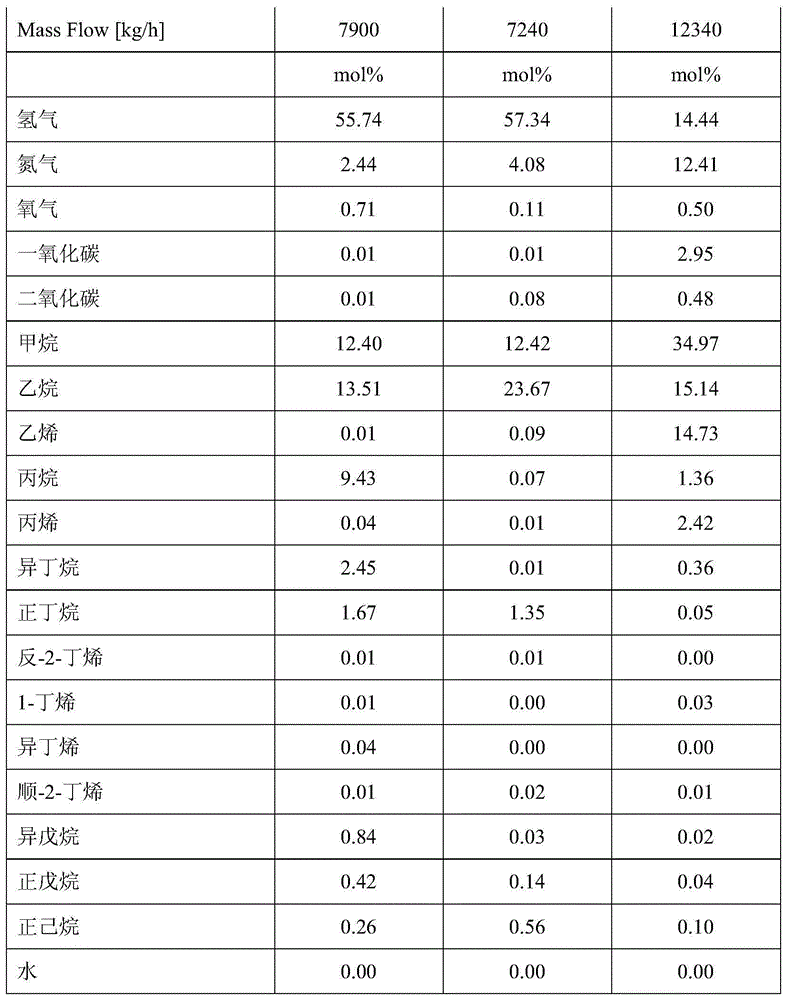

[0065] The dry gas composition is shown in Table 1,

[0066] Table 1

[0067]

[0068]

[0069] Refinery dry gas includes PSA stripping gas, light hydrocarbon dry gas and FCC dry gas, of which PSA stripping gas and light hydrocarbon dry gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com