Tri-shape shape memory conductive polymeric nanocomposite and preparation method thereof

A nano-composite material, conductive polymer technology, applied in conductive coatings, nanotechnology for materials and surface science, nanotechnology and other directions, can solve the problem of conductive materials not having simultaneous induction, electrical properties changes, etc., to improve the extension Sexual, selective and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

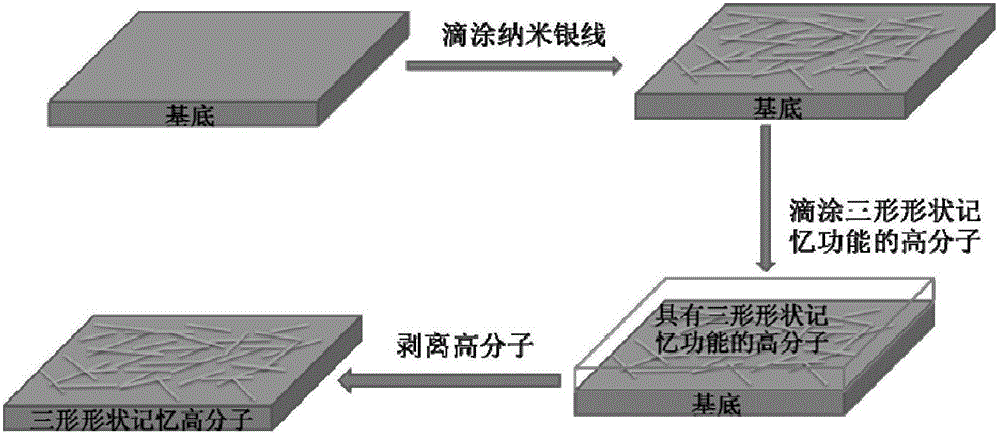

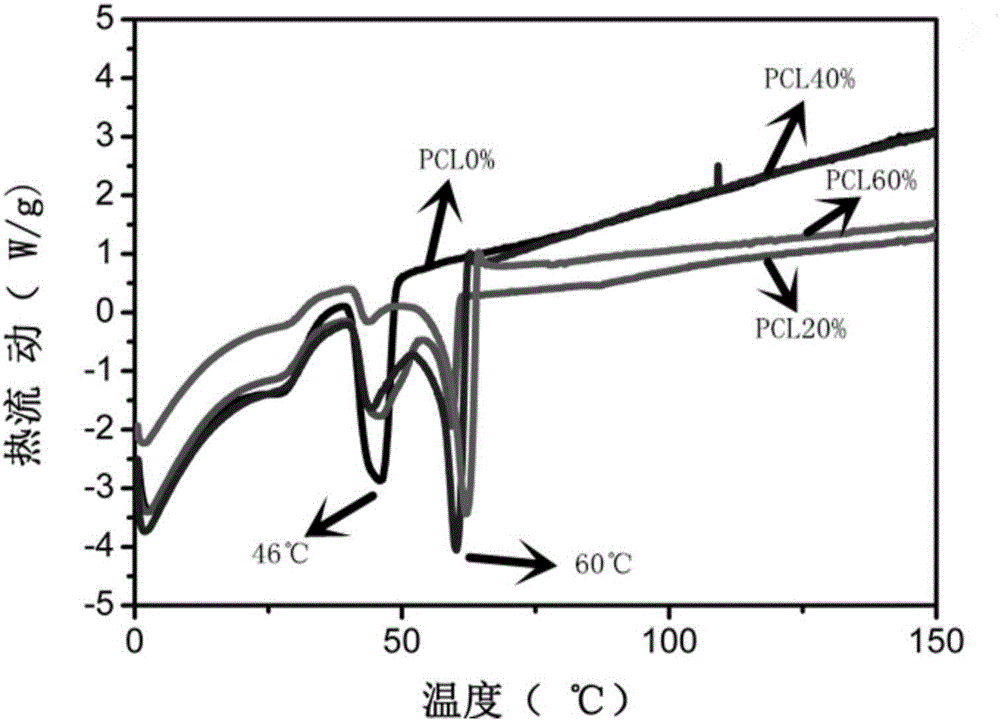

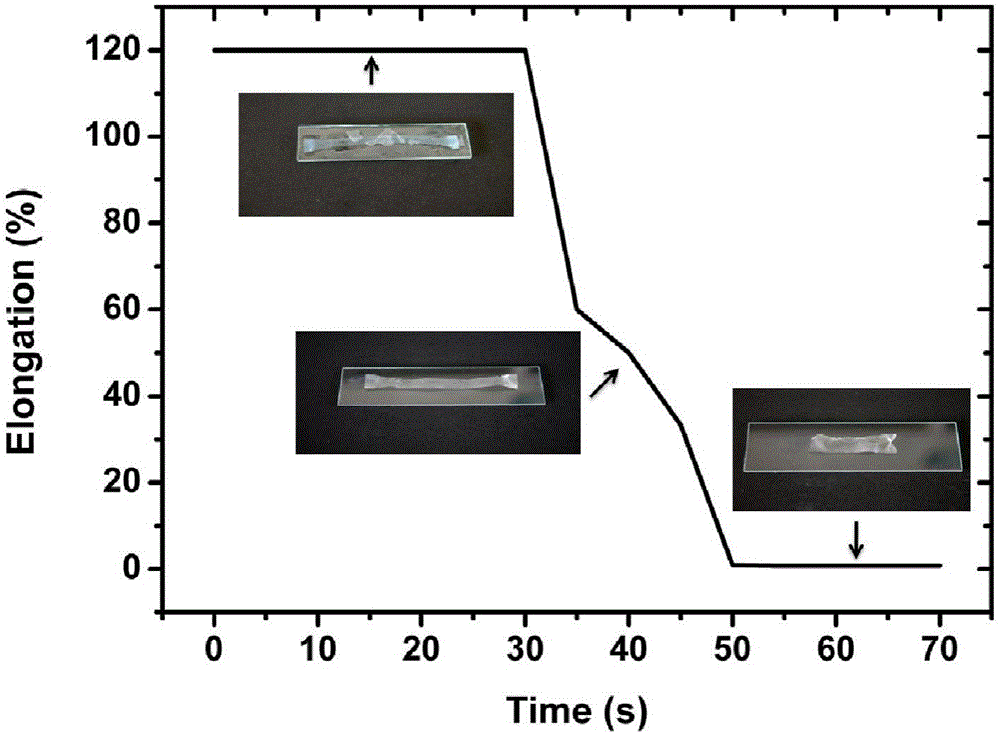

[0037] The preparation method includes the following steps: the conductive nano network structure is embedded in the upper surface layer through a transfer process; wherein, the composite surface layer provides electronic pathways, and the polymer substrate provides flexibility, mechanical properties and shape memory properties; Blending or chemical synthesis design polymer structure to obtain two thermal transition temperatures T1 and T2, after excipient treatment, two thermal transitions at different temperatures lead to three-shape deformation recovery. Wherein, the differential scanning calorimetry curve (DSC) of polymer material tests the glass transition temperature Tg of this polymer composite material 1 and Tg 2 like figure 2 Shown; The shape recovery of polymer composites with three-shape shape memory function is as follows image 3 shown.

[0038] Further, stretching and deformation at a higher temperature and cooling to a fixed shape, the resistance changes from...

Embodiment 1

[0046] Take nano-silver wire ethanol solution 3ml (concentration 1mg / ml), evenly drop-coat it on the glass substrate, dry it naturally to form a dense conductive film. Dissolve 200mg of polyurethane in 4ml of N,N dimethylacetamide, stir at an oil bath temperature of 70°C for 12 hours to obtain a blended solution, then spread the blended solution evenly on the conductive film, and heat it in an oven at 70°C dry in medium for 12 hours, and finally continue vacuum drying at 60° C. for 24 hours to obtain a conductive polymer nanocomposite material with a three-shape shape memory function containing polycaprolactone with a mass content of 0%.

[0047] The size of the conductive polymer nanocomposite material with double-switch three-shape shape memory function in this embodiment is 30mm*5mm, the resistance is 3 ohms, 100% stretched at 70°C, fixed at 10°C, the length of the film becomes 60mm, the resistance becomes 79 ohms, when the temperature rises to 30°C, the length of the film ...

Embodiment 2

[0049] Take nano-silver wire ethanol solution 3ml (concentration 1mg / ml), evenly drop-coat it on the glass substrate, dry it naturally to form a dense conductive film. 40mg of thermoplastic polycaprolactone and 160mg of polyurethane were dissolved in 4ml of N,N dimethylacetamide, stirred at an oil bath temperature of 70°C for 12 hours to obtain a blended solution, and then the blended solution was evenly spread on On the conductive film, dry in an oven at 70°C for 12 hours, and finally continue to dry in vacuum at 60°C for 24 hours to obtain a conductive polymer nanocomposite material with a three-shape shape memory function containing polycaprolactone with a mass content of 20%.

[0050] The size of the conductive polymer nanocomposite material with double-switch three-shape shape memory function in this embodiment is 30mm*5mm, the resistance is 3 ohms, 100% stretched at 70°C, fixed at 10°C, the length of the film becomes 60mm, the resistance becomes 91 ohms, when the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com