Electric heating compound fabric and preparation method thereof

An electrothermal composite and fabric technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, applications, etc., can solve the problems of lack of elasticity and durability, not light enough and invisible, uncomfortable to wear, etc., and improve wearing comfort , Good heating stability and good heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

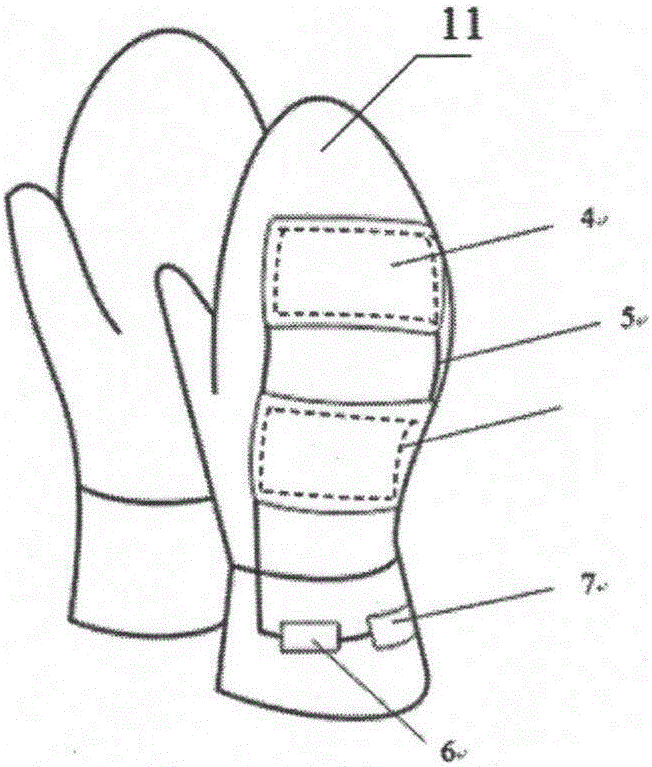

[0036] Example 1: Light and thin electric heating gloves

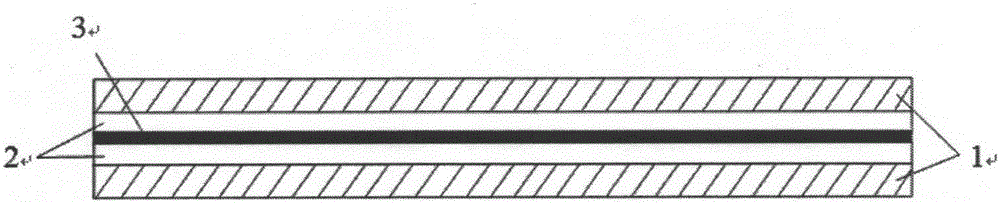

[0037] Such as figure 1 As shown, an electrothermal composite fabric includes a layer of elastic fabric 1, the upper surface of the elastic fabric 1 is bonded with a flexible nano-conductive film 3 through a liquid elastic adhesive 2, and the upper surface of the flexible nano-conductive film 3 is The surface is bonded to another layer of elastic fabric 1 by liquid elastic adhesive 2.

[0038] The specific steps of the above-mentioned preparation method of the electrothermal composite fabric are as follows:

[0039] Step 1: Immerse the carbon nanotube film in the graphene suspension for 3 hours, take it out, and let it dry naturally at room temperature to obtain a flexible nanoconductive film, and attach copper wire electrodes to both ends of the flexible nanoconductive film through conductive silver glue ;

[0040] Step 2: Using the elastic fabric 1 as an elastic attachment base, stretch it to an elongation rate of...

Embodiment 2

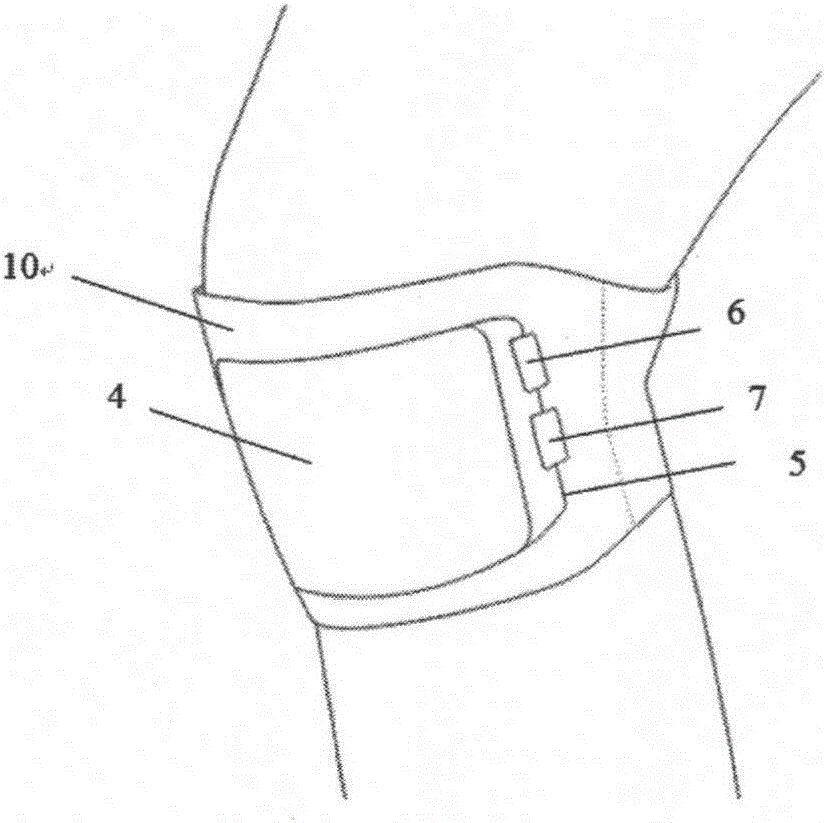

[0049] Example 2: Elastic Electric Sports Knee Brace

[0050] Such as figure 1 As shown, an electrothermal composite fabric includes a layer of elastic fabric 1, the upper surface of the elastic fabric 1 is bonded with a flexible nano-conductive film 3 through a liquid elastic adhesive 2, and the upper surface of the flexible nano-conductive film 3 is The surface is bonded to another layer of elastic fabric 1 by liquid elastic adhesive 2.

[0051] The specific steps of the above-mentioned preparation method of the electrothermal composite fabric are as follows:

[0052] Step 1: Dimensions 5×5cm 2 After soaking the carbon nanotube film in the graphene suspension for 3 hours, take it out, and dry it naturally at room temperature to obtain a flexible nanoconductive film, and adhere copper wire electrodes to the two ends of the flexible nanoconductive film through conductive silver glue;

[0053] Step 2: Use the elastic fabric 1 (outer layer) as the elastic attachment matrix, s...

Embodiment 3

[0063] Embodiment 3: elastic electric heating physiotherapy belt

[0064] Such as figure 1 As shown, an electrothermal composite fabric includes a layer of elastic fabric 1, the upper surface of the elastic fabric 1 is bonded with a flexible nano-conductive film 3 through a liquid elastic adhesive 2, and the upper surface of the flexible nano-conductive film 3 is The surface is bonded to another layer of elastic fabric 1 by liquid elastic adhesive 2.

[0065] The specific steps of the above-mentioned preparation method of the electrothermal composite fabric are as follows:

[0066] Step 1: After immersing the carbon nanotube film in the graphene suspension for 3 hours, take it out, and let it dry naturally at room temperature to obtain a flexible nanoconductive film. Coat both ends of the flexible nanoconductive film with conductive silver glue, and wire the copper wire The electrode is inserted into the conductive silver glue, so that the copper wire and the carbon nanotube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com