Preparation of flame-retardant polyester for preparing industrial yarn

A flame-retardant polyester and industrial yarn technology, which is applied in the manufacture of fire-resistant flame-retardant filaments, single-component polyester artificial filaments, etc., to achieve the effect of reducing and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

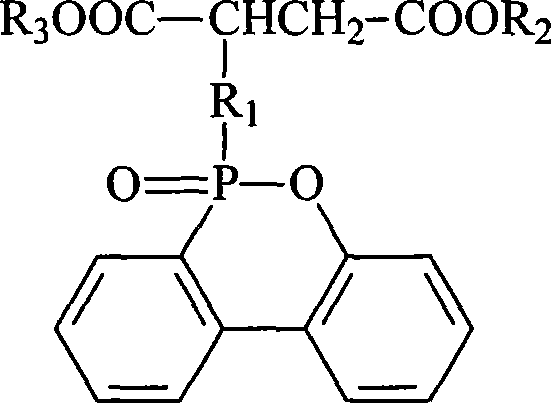

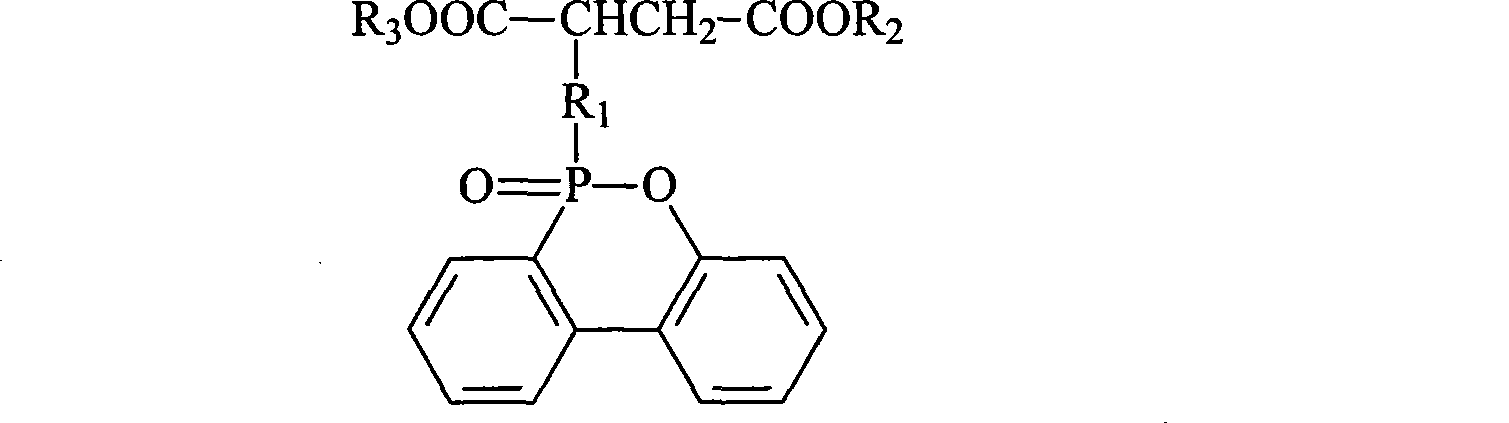

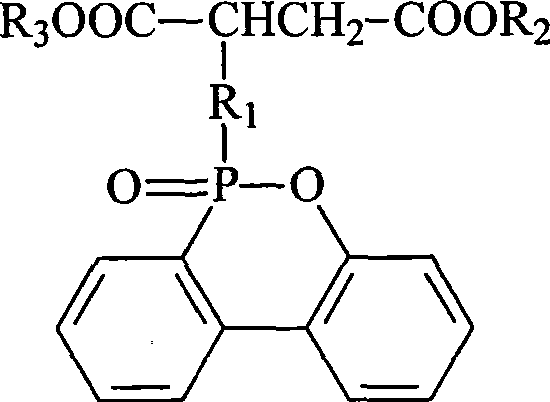

Image

Examples

Embodiment 1~4

[0028] 1. Esterification process:

[0029]Monomer terephthalic acid and ethylene glycol undergo esterification reaction, the molar ratio of monomer feed is terephthalic acid: ethylene glycol = 100: 110-200, the reaction temperature is 260-280 ° C, and the reaction pressure is 100-300 kPa , The residence time of the reactants is 1.5 to 4 hours.

[0030] The way of adding nano-kaolin is selected before the esterification reaction. When beating and mixing the esterification raw materials, a required amount of nano kaolin particles is added to the esterification raw materials, and the average particle diameter of the nano kaolin particles is 200-500 nm. The specific feeding amount of nano-kaolin particles in each embodiment is determined according to the content of nano-kaolin in the flame-retardant polyester product, and the content of nano-kaolin in the flame-retardant polyester product in each embodiment is shown in Table 1.

[0031] 2. Precondensation and polycondensation pr...

Embodiment 5~8

[0041] The method of adding nano-kaolin is changed to adding before the polycondensation reaction. First, the nano-kaolin particles, pentaerythritol and reactive flame retardant are beaten and mixed with ethylene glycol as a solvent to prepare a slurry with a total concentration of 20-45wt%. It is then added to the reaction system through the oligomer line. All the other are with embodiment 1~4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com