Preparation of flame-retardant polyester for preparing fiber

A technology of flame-retardant polyester and reactive flame retardant, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, etc., which can solve broken ends, unfavorable spinning processing, and influence on the degree of orientation of macromolecules and other problems, to achieve the effect of improving the decline in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0028] 1. Esterification process:

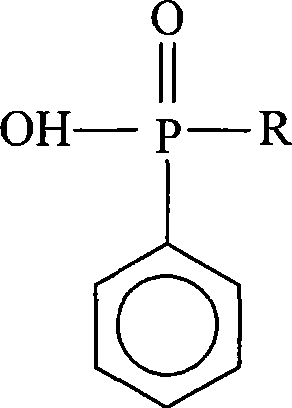

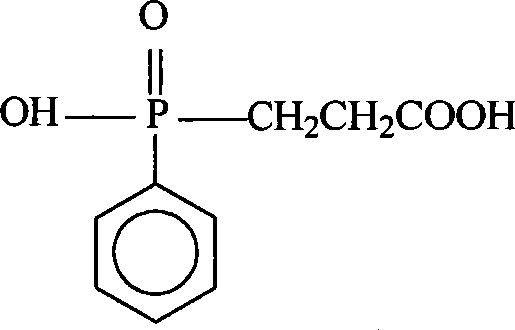

[0029] The monomer terephthalic acid and ethylene glycol, and the reactive flame retardant undergo esterification reaction, and the reactive flame retardant is a compound with the following structural formula:

[0030]

[0031] The feeding ratio of raw materials is controlled respectively as follows:

[0032] In molar ratio, terephthalic acid: ethylene glycol=100:110~200;

[0033] In terms of weight ratio, terephthalic acid: reactive flame retardant = 100: 1.40-7.50, see Table 1 for specific data and flame retardant content in flame-retardant polyester products.

[0034] The way of adding nano-kaolin is selected before the esterification reaction. When the raw materials are beaten and mixed before the esterification reaction, the required amount of nano kaolin particles is added to the esterification raw materials, and the average particle diameter of the nano kaolin particles is 200-500nm. The specific feeding amount of nano-kaolin pa...

Embodiment 5~8

[0041] The method of adding nano-kaolin is changed to adding before the polycondensation reaction. Firstly, nano-kaolin particles are beaten and mixed with ethylene glycol to prepare a slurry with a concentration of 20-45 wt%, and then added to the reaction system through the oligomer pipeline. All the other are with embodiment 1~4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com