PrPrearation method for graphene film

A graphene film and substrate technology, applied in the field of graphene film preparation, can solve the problems of accelerating the development of graphene technology and practical application, and achieve the effects of excellent optoelectronic properties and easy size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

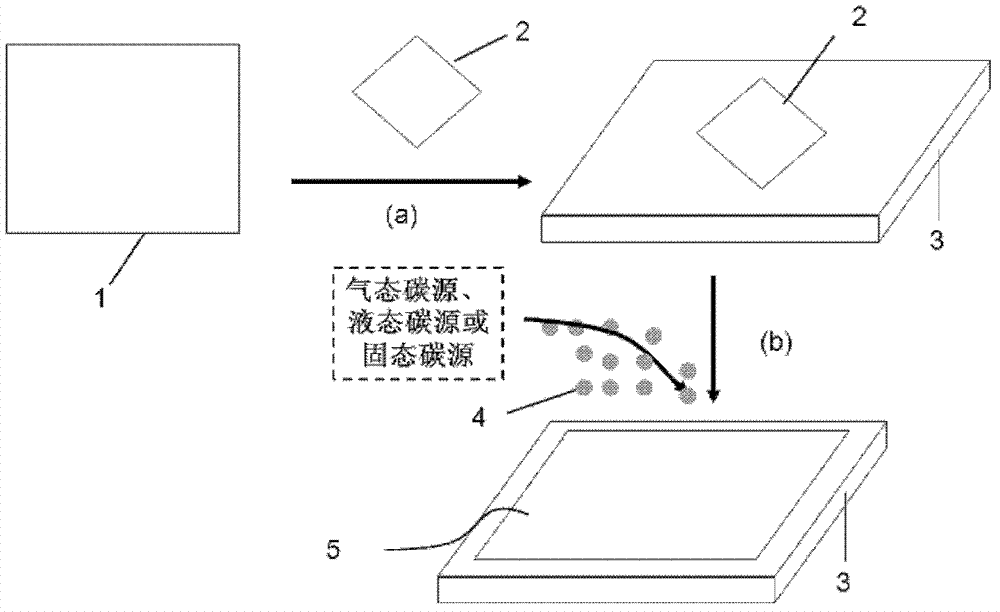

[0021] Embodiment 1: utilize the monolayer graphene prepared by mechanical exfoliation method as the graphene platelet that induces graphene large-area growth, on SiO 2 Graphene films grown on substrates

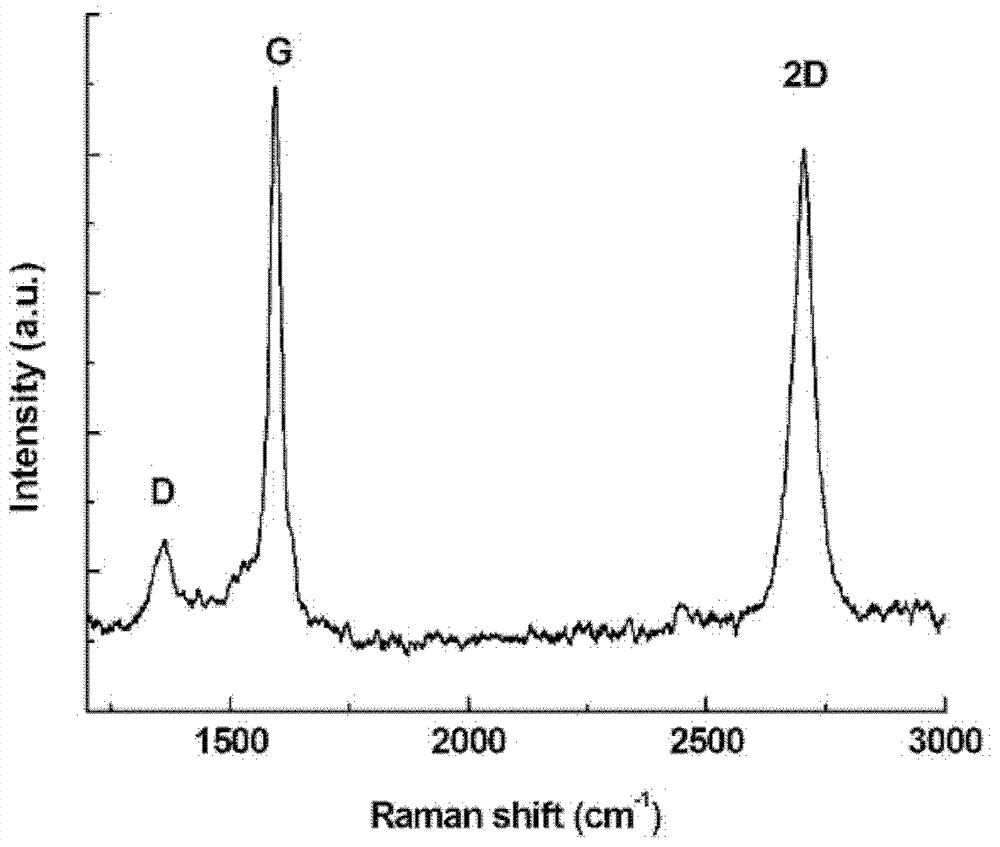

[0022] Single-layer graphene was prepared from high-temperature cracked graphite by mechanical exfoliation using 3M's Scotch tape and transferred to SiO 2 Graphene thin film flakes on the substrate as induced graphene growth; SiO with graphene thin flakes 2 The substrate is placed in an ultra-high vacuum (6.0×10 -9 torr) heat treatment at 1000 oC for 5 minutes; subsequently, pass H at 800oC 2 with C 2 h 4 mixed gas, the SiO 2 Graphene flakes on the substrate induce graphene growth for 5 minutes; 2 A large area of single-layer graphene was grown on the substrate ( figure 2 ).

[0023] Effect: SiO 2 It is an important dielectric material for contemporary silicon-based electronic devices and digital / logic circuits, directly on SiO 2 The growth of graphene films o...

Embodiment 2

[0024] Embodiment 2: Utilize the bilayer graphene prepared by chemical vapor deposition method as the graphene flakes that induce graphene large-area growth, prepare graphene film on polymer polyethylene terephthalate (PET) substrate

[0025] The polished and surface-treated 25um thick Cu sheet was placed in a high vacuum (1.0×10 -8 torr) was heat-treated at 1000 oC for 30 minutes; subsequently, through CH 4 Gas and H 2 Gas growth was performed for 2 minutes; the temperature was lowered to room temperature at a cooling rate of 15oC / min, thereby obtaining double-layer graphene on the Cu film. Transfer a small piece of graphene from Cu to polymer PET: Spin-coat a 500nm polymethylmethacrylate (PMMA) layer on the surface of the synthesized graphene, place the PMMA-coated graphene / Cu in a ferric nitrate solution to corrode the Cu film Drop, so as to obtain PMMA / graphene, then transfer PMMA / graphene to PET, and then dissolve PMMA with acetone, so that small pieces of double-laye...

Embodiment 3

[0028] Embodiment 3: The monolayer graphene prepared by mechanical exfoliation method is used as the graphene flake that induces graphene to grow in a large area, and grows graphene on a gold substrate

[0029] Using Scotch tape of 3M company to prepare single-layer graphene from high-temperature pyrolysis graphite by mechanical exfoliation method, and transfer it to Au substrate as graphene flakes that induce large-area growth of graphene on Au. The Au substrate loaded with graphene flakes is placed in the sputtering chamber, and carbon atoms are sputtered from the amorphous carbon target onto the Au substrate by sputtering method, so that the transferred graphene flakes induce Graphene was grown at a substrate temperature of 300 oC ( Figure 4 ).

[0030] Effect: The resources of precious metal materials such as gold are limited, while graphene has excellent mechanical strength and transparency. Directly coating a layer of graphene on the surface of gold can help protect p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com