Preparation method of metal nanoparticle modified graphene composite material

A technology of metal nanoparticles and composite materials, which is applied in the field of preparation of graphene composite materials, can solve the problems of unfavorable scale production and utilization of final products, difficult control and adjustment of metal or oxide morphology, cumbersome steps, etc., so as to facilitate the promotion Utilization, controllable shape, and scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The concrete steps of preparation are:

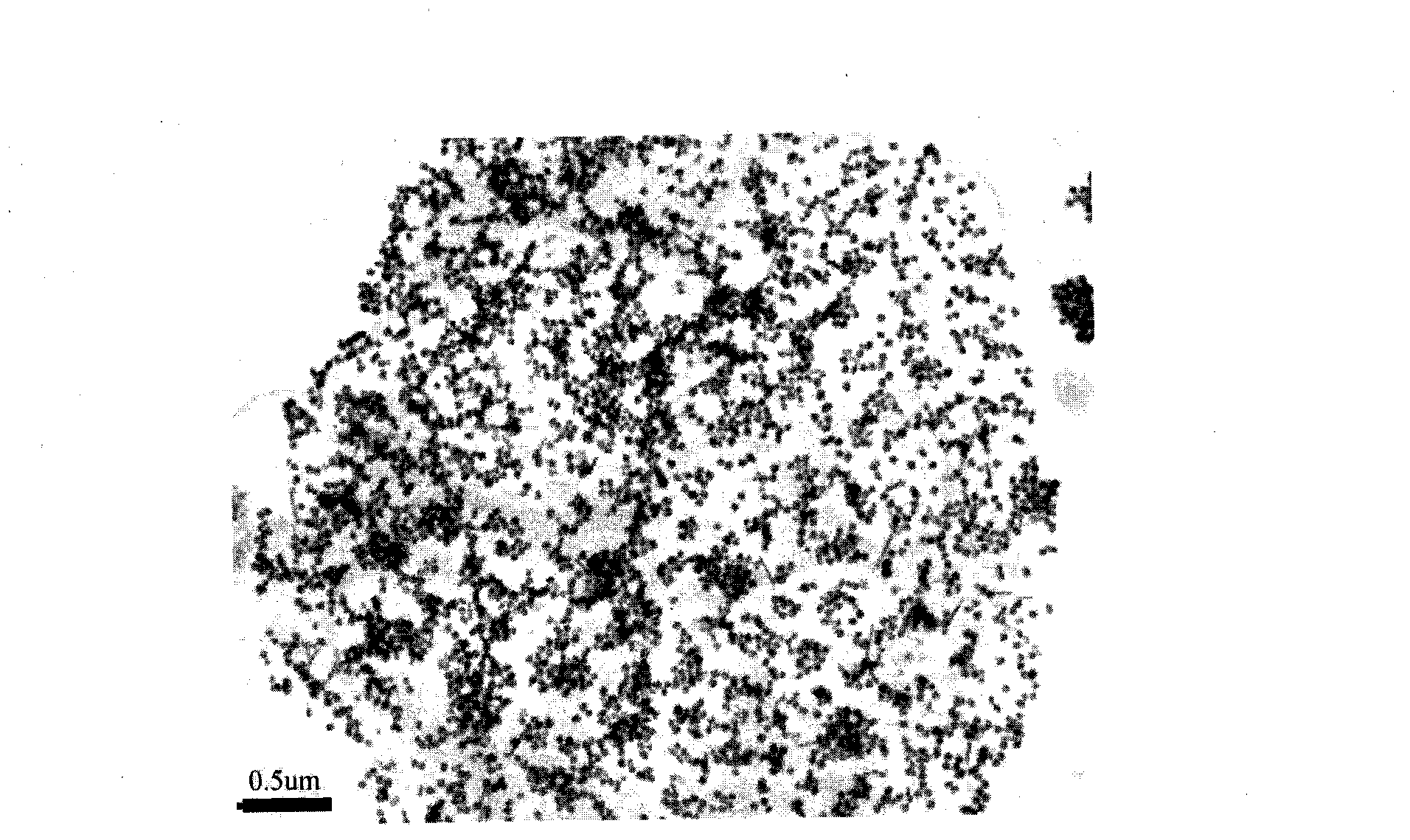

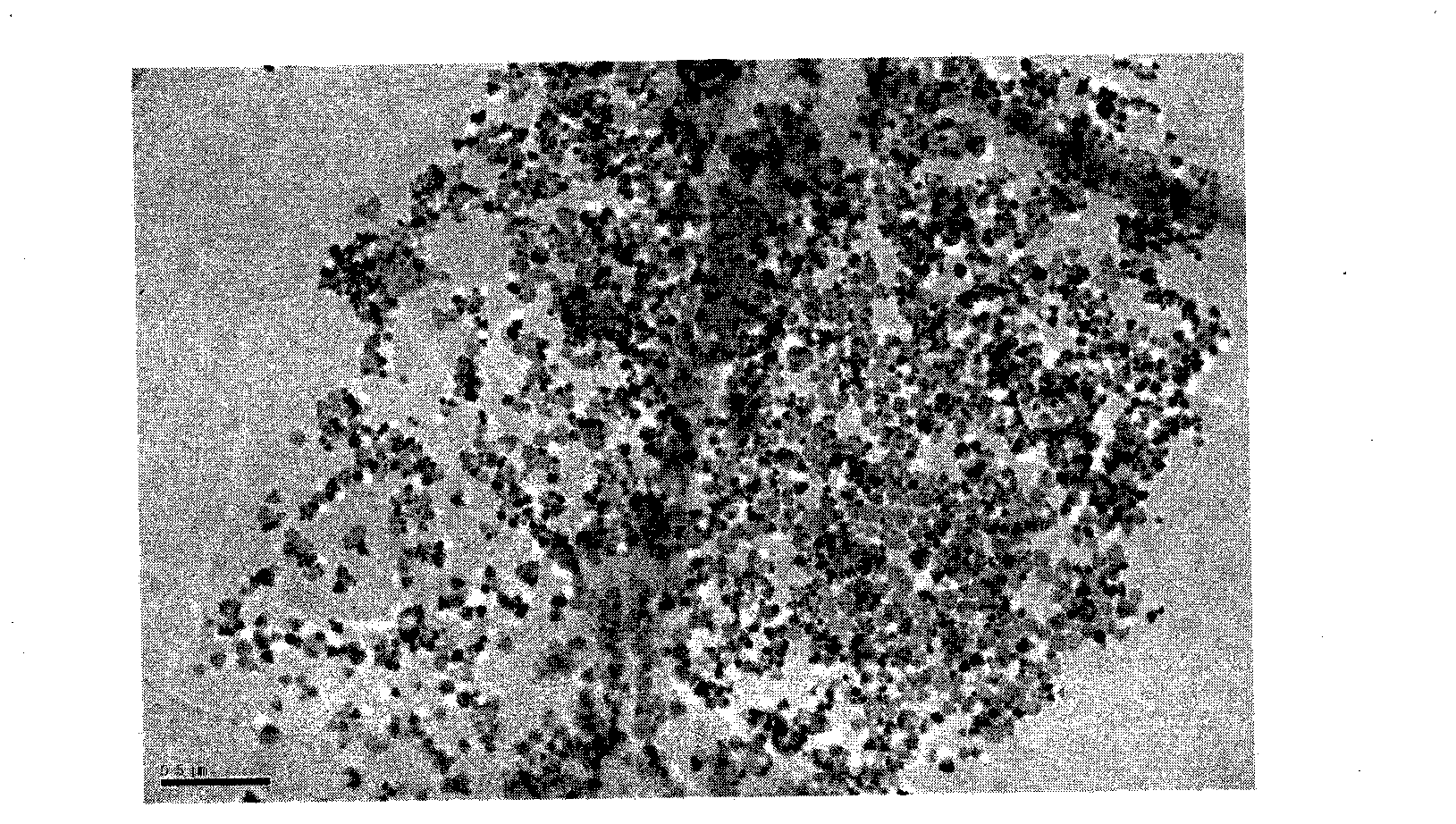

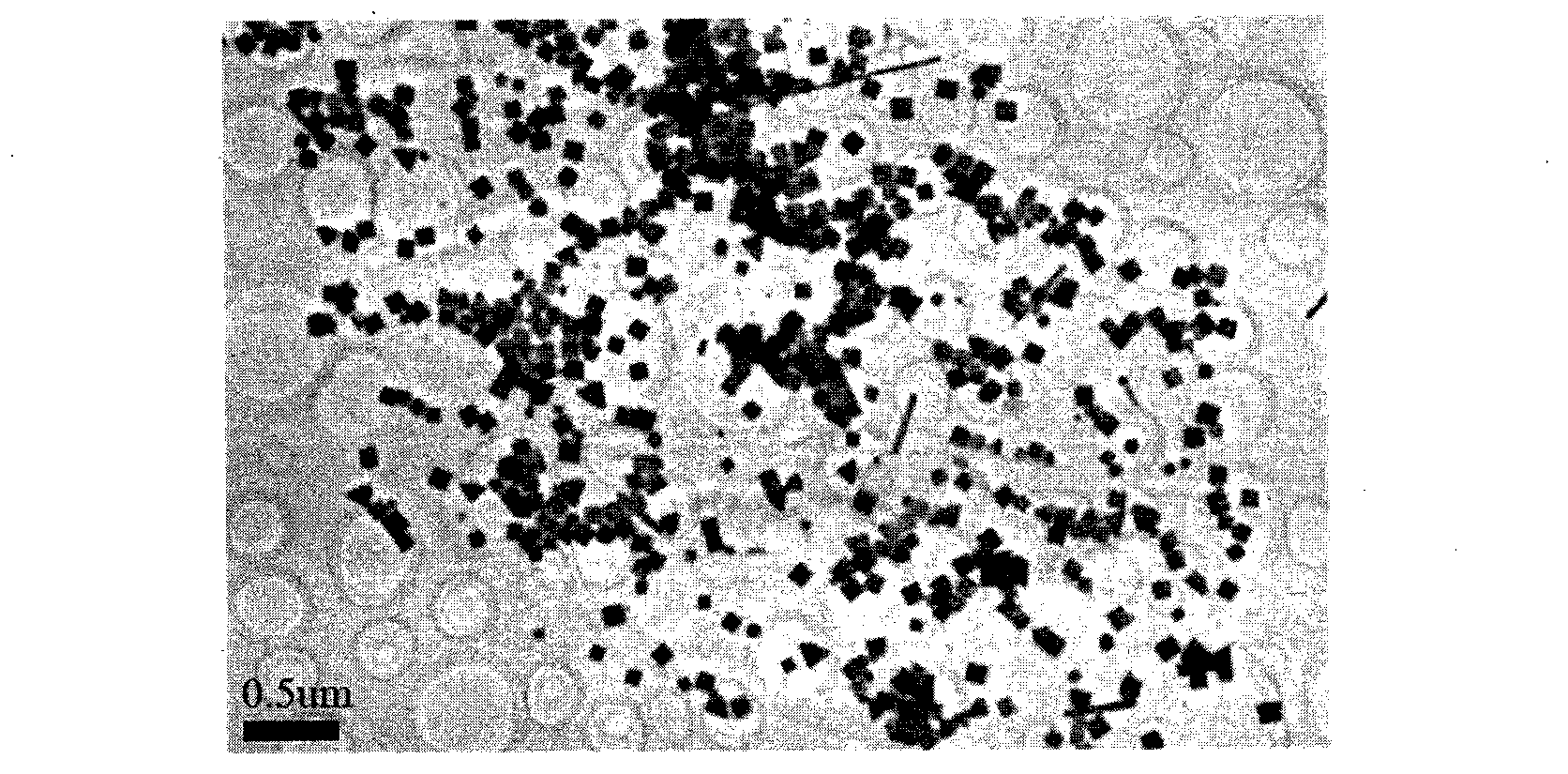

[0025] First, the graphene sheets, metal nanoparticles and ethanol are mixed according to a mass ratio of 1:100:500, and ultrasonicated for 10 minutes to obtain a mixed liquid; wherein, the metal nanoparticles are silver nanospheres. Then the mixture was centrifuged 5 times at a speed of 12000r / min, each time for 10min, to obtain a mixture similar to figure 1 The graphene composite decorated with metal nanoparticles is shown.

Embodiment 2

[0027] The concrete steps of preparation are:

[0028] Firstly, the graphene sheets, metal nanoparticles and ethanol are mixed according to the mass ratio of 1.5:88:630, and ultrasonicated for 11 minutes to obtain a mixed liquid; wherein, the metal nanoparticles are silver nanospheres. Then the mixture was centrifuged 4 times at a speed of 13500r / min, each time for 11min, to obtain a mixture similar to figure 1 The graphene composite decorated with metal nanoparticles is shown.

Embodiment 3

[0030] The concrete steps of preparation are:

[0031] Firstly, the graphene sheets, metal nanoparticles and ethanol are mixed according to the mass ratio of 2:75:750, and ultrasonicated for 12 minutes to obtain a mixed liquid; wherein, the metal nanoparticles are silver nanospheres. Then the mixed solution was centrifuged 4 times at a speed of 14300r / min, each time for 12min, to obtain the following figure 1 The graphene composite decorated with metal nanoparticles is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com