Preparation methods of flexible substrate-based graphene film and flexible substrate-based graphene composite film

A graphene film and flexible substrate technology, which is applied in the field of preparation of graphene and its composite film, can solve the problems of difficult large-area preparation, limited film area by devices, and high preparation cost, achieves good flexibility and flatness, and facilitates peeling and transfer, easy to operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

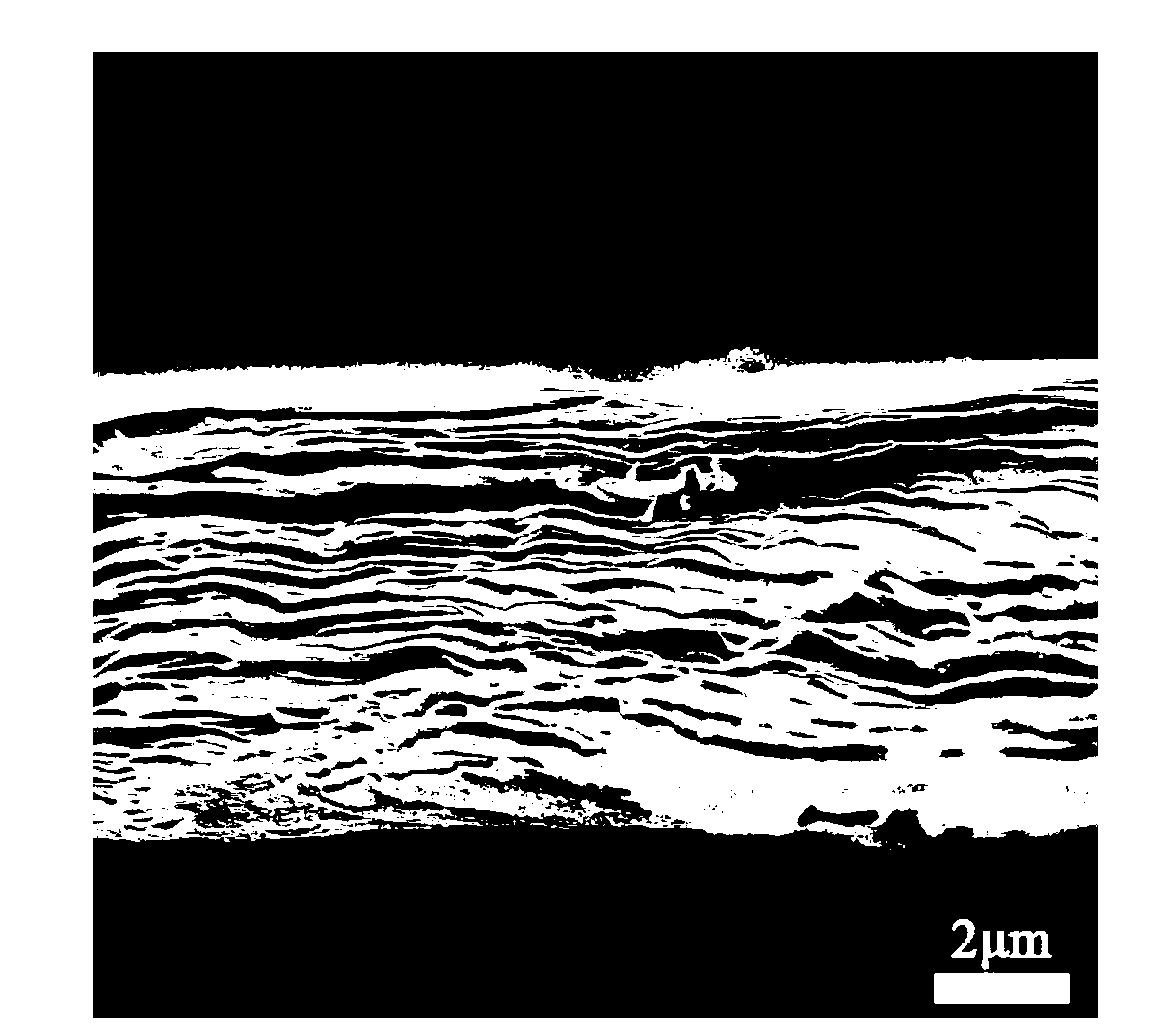

Image

Examples

Embodiment 1

[0030] Pour 300ml of a graphene oxide aqueous solution with a mass concentration of 0.1mg / ml on, for example, commercial printing paper of A4 size, use a stainless steel rod rolling method to make it flow and form a uniformly covered film layer on the entire surface of the drawing paper , and then perform drying and curing treatment, thereby obtaining graphene oxide paper;

[0031] On the surface of the graphene oxide film layer of the graphene oxide paper, the polydimethylsiloxane (PDMS) liquid is also rolled and covered with a stainless steel rod to obtain a PDMS layer, and it is placed at 80-90 degrees perform curing;

[0032] At room temperature, the graphene oxide paper coated with polydimethylsiloxane layer was soaked in 45% hydroiodic acid to perform the reduction reaction. During the reduction process, the printing paper was hydrolyzed and simultaneously reacted with hydrogen The acid reacts to generate air bubbles, thereby impelling the graphene film layer combined w...

Embodiment 2

[0034] Pour 300ml of graphene oxide aqueous solution with a mass concentration of 10mg / ml on commercial printing paper of A4 size, use a stainless steel rod rolling method to make it flow and form a layer of evenly covered film on the entire surface of the drawing paper, Then perform a drying and curing process, thereby obtaining graphene oxide paper;

[0035]On the surface of the graphene oxide film layer of the graphene oxide paper, the polydimethylsiloxane (PDMS) liquid is also rolled and covered with a stainless steel rod to obtain a PDMS layer, and it is placed at 80-90 degrees perform curing;

[0036] At room temperature, the graphene oxide paper coated with polydimethylsiloxane layer was soaked in 50% hydroiodic acid to perform the reduction reaction. During the reduction process, the printing paper was hydrolyzed and simultaneously reacted with hydrogen iodide The acid reacts to generate air bubbles, thereby impelling the graphene film layer combined with the polydime...

Embodiment 3

[0038] Add 50 mg of multi-walled carbon nanotubes to 40 ml of graphene oxide aqueous solution with a mass concentration of 2 mg / ml and perform ultrasonic dispersion for 2 hours to obtain a mixed solution. The mixed solution is coated on a flat surface with a specification of 40 cm* by a coating roller. 40cm kraft paper, and form a layer of uniformly covered composite film on the entire surface, and then perform drying and curing treatment;

[0039] Coating a polydimethylsiloxane layer on the surface of the graphene oxide / carbon nanotube composite film layer of the kraft paper, and performing curing treatment on it;

[0040] The kraft paper bearing the graphene oxide / carbon nanotube composite film layer and the polydimethylsiloxane layer was soaked in 55% hydroiodic acid to perform the reduction reaction. During the reduction process, the kraft paper was hydrolyzed and simultaneously Reacting with hydriodic acid generates bubbles, thereby impelling the graphene / carbon nanotube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com