Grapheme foam and preparation method thereof

A graphene foam and graphene technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as difficult to disperse, easy to agglomerate, efficient energy storage limitations, etc., to prevent agglomeration, specific surface area The effect of enhancement and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, prepare graphene foam

[0038] The first step is to clean the nickel foam template

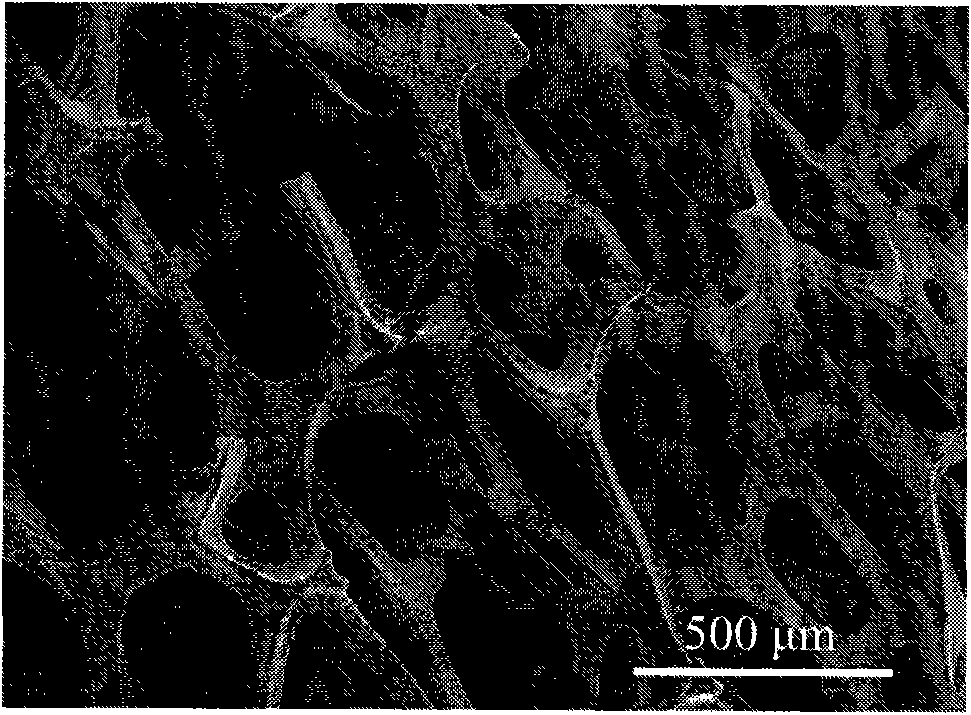

[0039] Nickel foam ( figure 1 ) were sequentially ultrasonically cleaned with deionized water, acetone, and ethanol for 30 minutes and dried;

[0040] The second step is to calcinate the nickel foam template

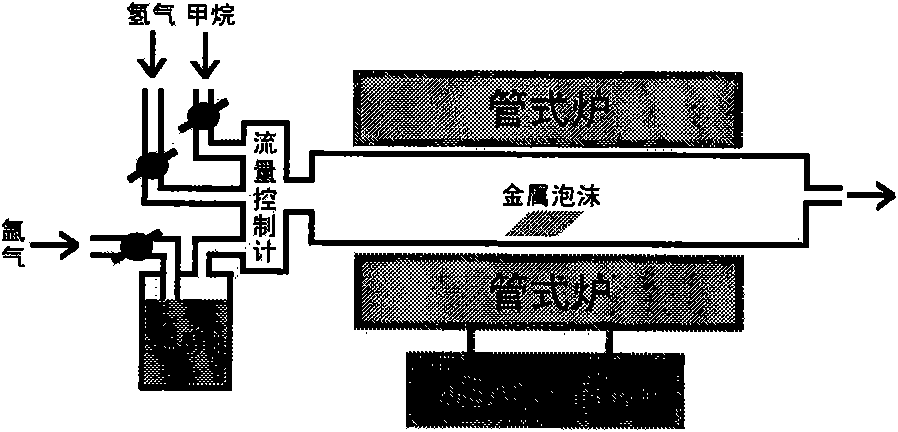

[0041] The experimental equipment used is as figure 2 As shown, put the nickel foam into the quartz tube of the tube furnace, evacuate to reduce the pressure in the tube to below 10Pa, and then inject hydrogen to the normal pressure, and repeatedly remove the air in the tube three times. Control the hydrogen flow rate to 50 sccm, heat up the temperature, and when the temperature rises to 1000°C, continue to keep the temperature constant for 0.5-1 hour;

[0042] The third step, growing graphene (that is, preparing graphene-modified nickel foam)

[0043] Maintain the temperature at 1000°C, feed methane and hydrogen, the gas flow rate is 30sccm methane, 50sccm hydro...

Embodiment 2

[0048] Embodiment 2, prepare graphene foam

[0049] According to the preparation method in Example 1, after calcining at 1000° C. for 0.5-1 hour, the temperature was lowered to 850° C., and 30 sccm argon was passed into a tank containing ethanol for bubbling, and ethanol was a carbon source for graphene growth. Scanning electron microscopy characterization of the as-prepared graphene-modified nickel foam, as Figure 8 shown. Graphene is attached to the surface of nickel foam, and there are wrinkles in graphene due to the different shrinkage coefficients of graphene and nickel foam.

Embodiment 3

[0050] Embodiment 3, prepare graphene foam

[0051] According to the preparation method in Example 1, the difference is that the copper foam is used as a growth template, and the copper foam is removed with a concentration of 0.05-0.1g / ml ferric chloride or ferric nitrate, the scanning electron of the prepared graphene-modified copper foam Microscopic characterization, such as Figure 9 shown. Graphene is attached to the surface of copper foam, and there are wrinkles in graphene due to the different shrinkage coefficients of graphene and copper foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com