Lithium metal secondary battery negative electrode and preparation method thereof

A secondary battery and lithium metal technology, which is applied in the field of lithium metal secondary battery negative electrode and its modification, can solve the problems of low battery coulombic efficiency, lower battery energy density, lithium negative electrode volume expansion, etc., to improve coulombic efficiency, reduce Effect of volume expansion and inhibition of dendrite formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

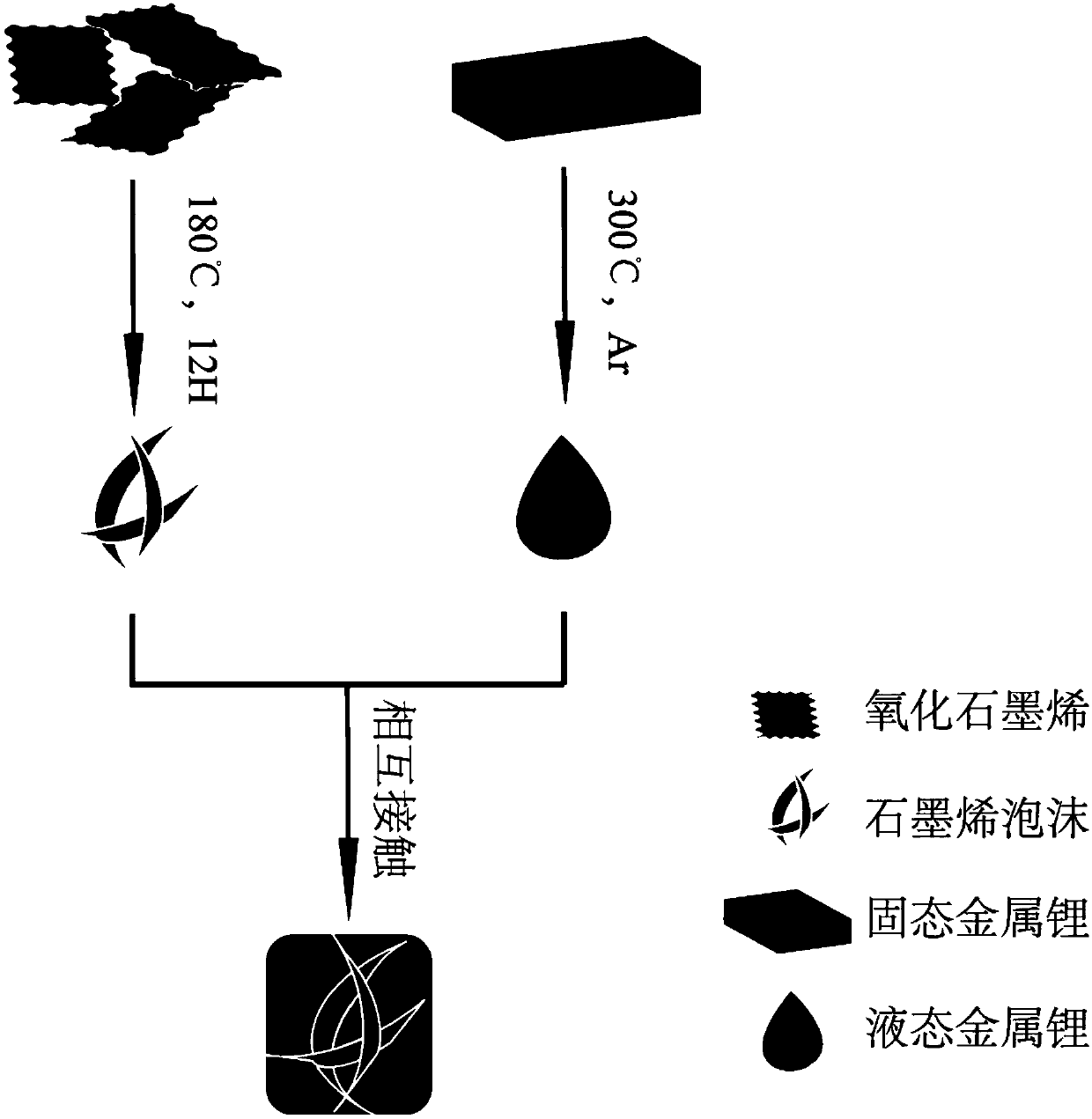

[0056] The present invention also provides a preparation method of a lithium metal secondary battery negative electrode, comprising the following steps:

[0057] 1) After the graphene oxide aqueous solution is reduced by a hydrothermal method, a graphene hydrogel is obtained, and then after freeze-drying, a graphene foam is obtained;

[0058] 2) After the graphene foam obtained in the above steps is mixed with liquid metal lithium, the lithium metal secondary battery negative electrode is obtained.

[0059] In the invention, the graphene oxide aqueous solution is firstly reduced by a hydrothermal method to obtain a graphene hydrogel, and then freeze-dried to obtain a graphene foam.

[0060] The concentration of the graphene oxide aqueous solution is not particularly limited in the present invention, it can be purchased commercially or prepared according to a conventional method with a conventional concentration well known to those skilled in the art, and those skilled in the a...

Embodiment 1

[0090] 1. Prepare graphene oxide by modified Hummers method.

[0091] Add 500mg flake graphite into the mixed solution of sodium nitrate (500mg) and concentrated sulfuric acid (46ml), stir and control the temperature of the water bath to be less than 10°C, keep stirring and slowly add potassium permanganate (3g); after 30 minutes, transfer the reaction system to Put it in a water bath at 35°C, and keep stirring until the solution becomes colloidal; add 120ml of deionized water, then move the reaction system to a water bath at 95°C, stir for one hour, and add 5% H 2 o 2 Solution 15ml; wash with 1M dilute hydrochloric acid (500ml), and then fully wash with deionized water until the pH of the filtrate is greater than 5; after ultrasonic treatment for 1 hour, freeze-dry to obtain graphene oxide powder.

[0092] 2. Dissolve graphene oxide powder in water, conduct ultrasonic treatment for 2 hours, and prepare 4mg·ml -1 The graphene oxide solution is reduced by the hydrothermal met...

Embodiment 2

[0104] 1. Prepare graphene oxide by modified Hummers method.

[0105] Add 500mg flake graphite into the mixed solution of sodium nitrate (500mg) and concentrated sulfuric acid (46ml), stir and control the temperature of the water bath to be less than 10°C, keep stirring and slowly add potassium permanganate (3g); after 30 minutes, transfer the reaction system to Put it in a water bath at 35°C, and keep stirring until the solution becomes colloidal; add 120ml of deionized water, then move the reaction system to a water bath at 95°C, stir for one hour, and add 5% H 2 o 2 Solution 15ml; wash with 1M dilute hydrochloric acid (500ml), and then fully wash with deionized water until the pH of the filtrate is greater than 5; after ultrasonic treatment for 1 hour, freeze-dry to obtain graphene oxide powder.

[0106] 2. Dissolve graphene oxide powder in water, conduct ultrasonic treatment for 2 hours, and prepare 4mg·ml -1 The graphene oxide solution is reduced by the hydrothermal met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com