Preparation method of anisotropic graphene foam

A graphene foam and anisotropic technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex hard template preparation process, high price, difficult control of process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

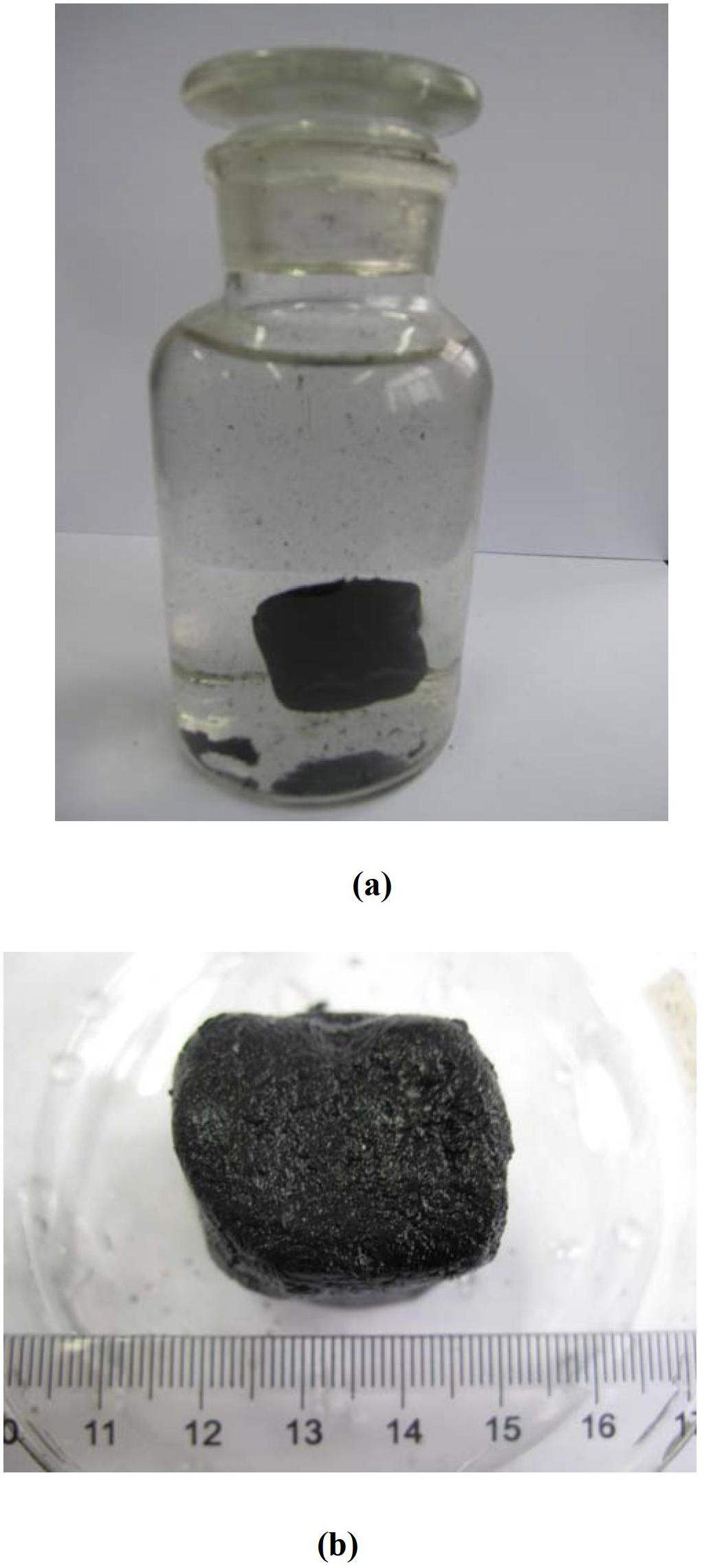

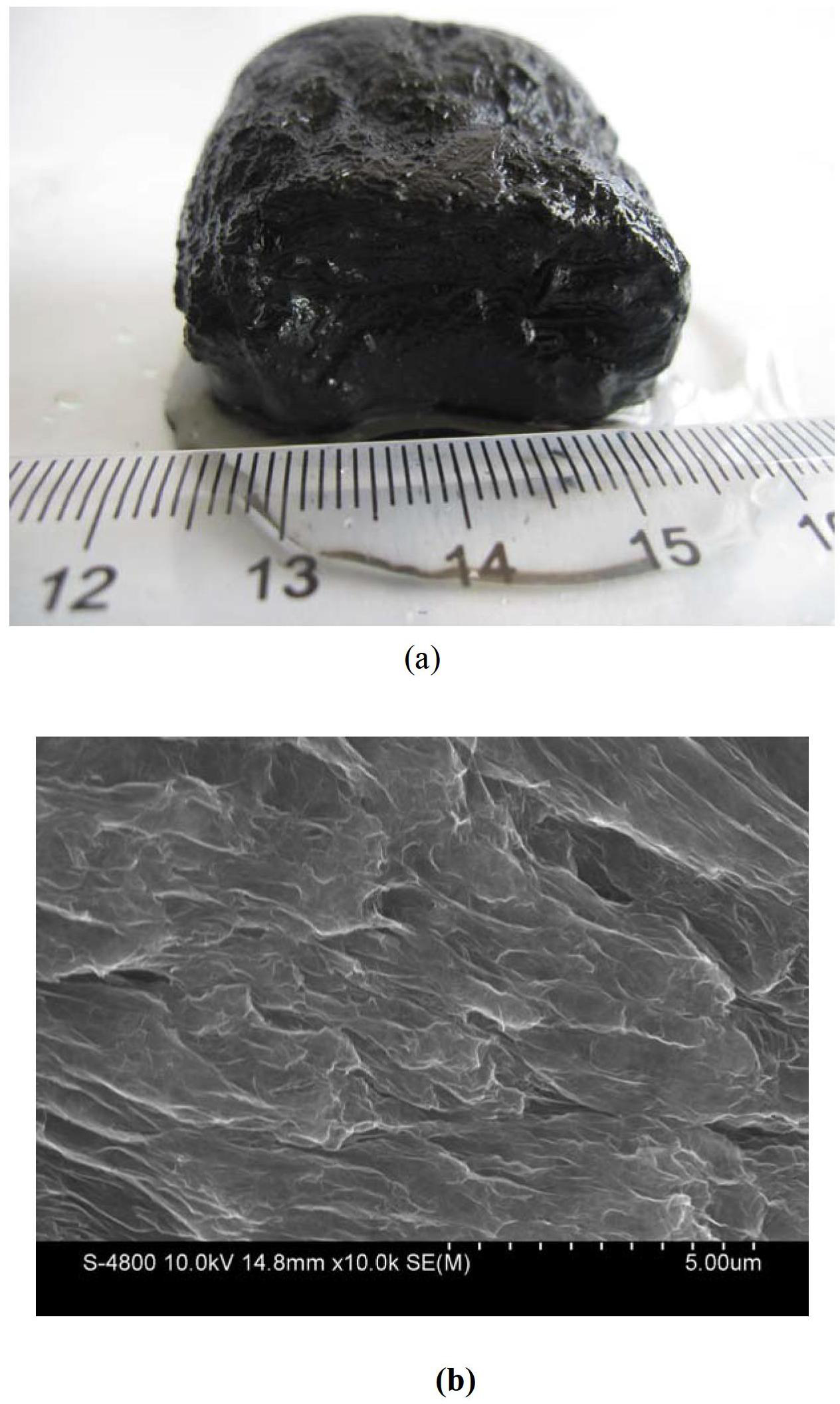

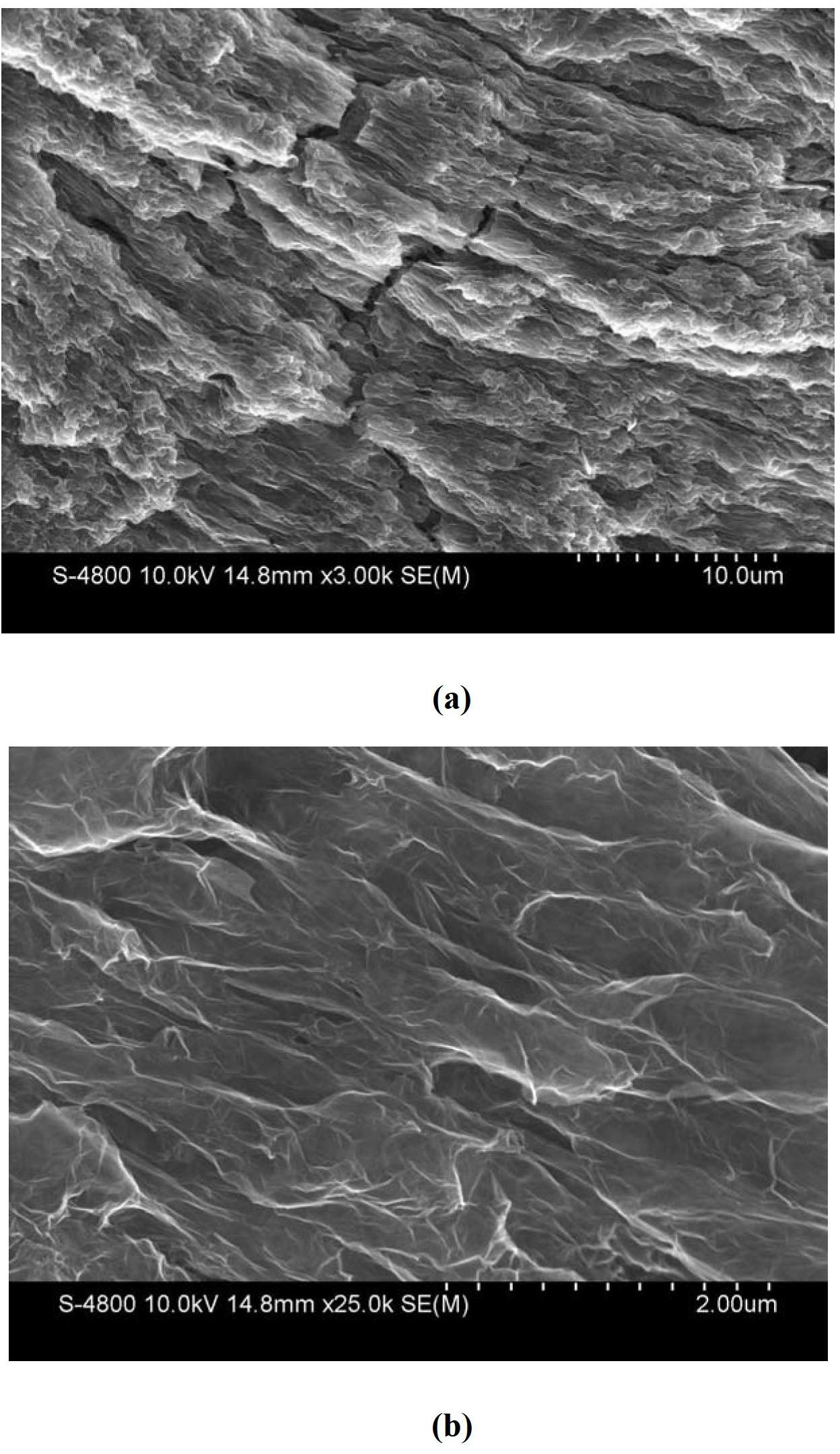

Embodiment 1

[0026] Graphite oxide was prepared by the Hummers method: In an ice bath, mix 10g of graphite powder and 5g of sodium nitrate with 230mL of concentrated sulfuric acid, and slowly add 30g of KMnO 4 ; Transfer it to a 35°C water bath for 30 minutes, then gradually add 460mL of deionized water, and continue to react for 40 minutes when the temperature rises to 98°C, the mixture turns from brown to bright yellow, further dilute with water, and use the mass fraction 30% H 2 o 2 Solution treatment, neutralization of unreacted permanganate, centrifugal filtration and repeated washing of the filter cake, and finally vacuum drying to obtain graphite oxide; grind graphite oxide, prepare 100mL of 2mg / mL suspension in water, ultrasonic treatment for 30min, A homogeneous and stable graphene oxide colloidal suspension was obtained; 0.2 g of surfactant polyvinylpyrrolidone (PVP-K30) was added, ultrasonically dissolved, and 1 g of L-cysteine was added to obtain a stable graphene dispersion...

Embodiment 2

[0028]Adopt the Staudenmaier method to prepare graphite oxide: first prepare the mixed solution of fuming nitric acid (27ml) and the vitriol oil (87.5ml) in the three-necked flask, then place the three-necked flask to cool in an ice bath, then 5g graphite powder is stirred (note: the three-neck flask needs to be placed in an ice bath all the time to slow down the reaction speed and avoid explosion), add 55g of sodium chlorate to the above reaction system, and continue stirring for 96 hours. After the reaction is over, the reaction The mixture was filtered and washed to obtain graphite oxide; grind the graphite oxide, prepare 100 mL of a 2 mg / mL suspension in water, and ultrasonicate for 30 minutes to obtain a homogeneous and stable graphene oxide colloidal suspension; add 0.2 g of surfactant sodium polyacrylate , ultrasonically dissolved, and 2 g of sodium citrate was added; the dispersion was heated to 95° C. for 4 hours, and then rapidly cooled to obtain a graphene foam.

Embodiment 3

[0030] Graphite oxide was prepared by the modified Brodie method: 10 g of graphite powder and 85 g of sodium chlorate were mixed with 200 mL of fuming nitric acid in an ice bath, and stirred at room temperature for 24 hours. After the reaction is finished, centrifugally filter and repeatedly wash the filter cake, purify, and finally vacuum-dry it to obtain graphite oxide. Grind graphite oxide, prepare 100 mL of a 2 mg / mL suspension in water, and ultrasonically treat it for 30 min to obtain a homogeneous and stable graphene oxide colloidal suspension. Add 2 g of ascorbic acid, ultrasonically dissolve to obtain a stable graphene dispersion. The graphene dispersion was irradiated with microwaves for 15 minutes, and the graphene foam could be obtained in 12 hours after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com