High-strength and high-heat-conduction three-dimensional graphene heat dissipating material and preparation method thereof

A technology of heat dissipation material and graphene dispersion, applied in the field of high thermal conductivity materials, can solve the problems of increased phonon scattering, large interface thermal resistance, large heat flux, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

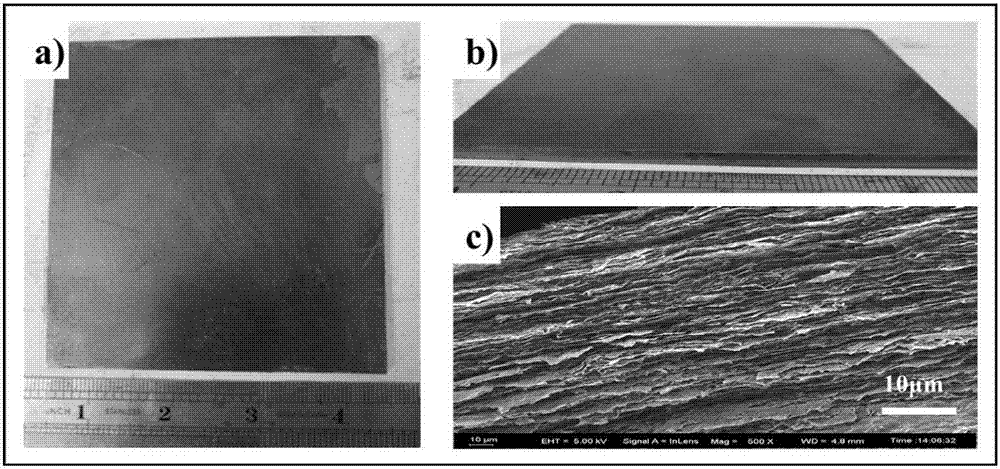

[0031] The construction method of the high-strength and high-thermal conductivity three-dimensional graphene heat dissipation material described in this embodiment is specifically carried out according to the following steps:

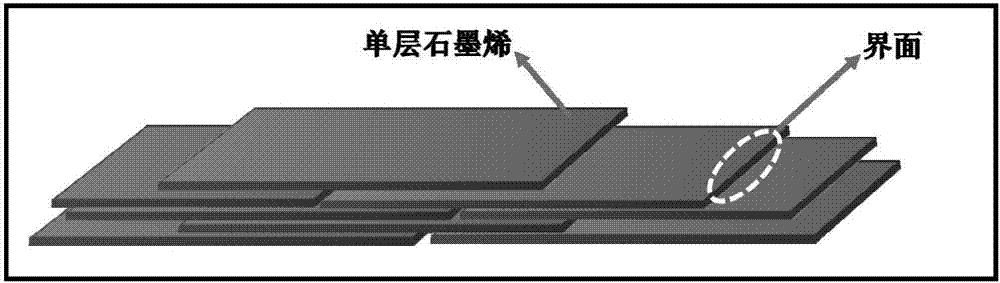

[0032] 1) Preparation of graphene oxide dispersion: disperse single-layer graphene oxide powder with a size of 20 to 30 microns in deionized water, and perform ultrasonic treatment for 60 minutes at a frequency of 10KHz to form a uniform solution with a concentration of 0.1 mg / mL graphene oxide dispersion;

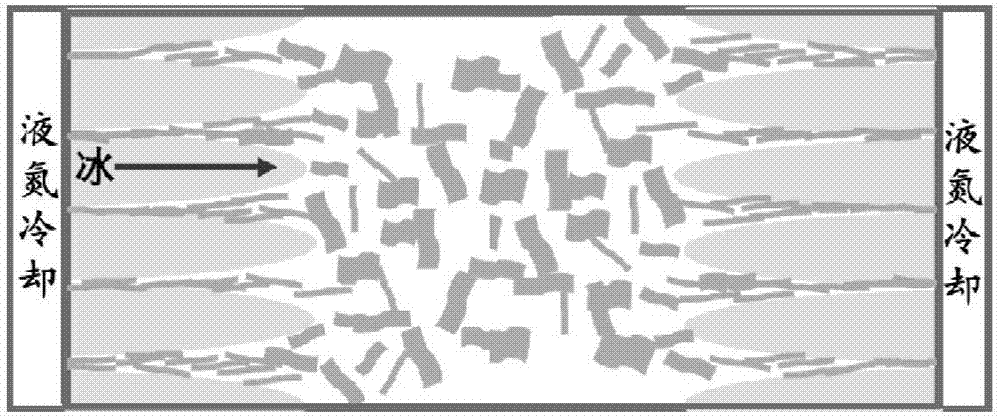

[0033] 2) High orientation treatment of graphene oxide: put the graphene oxide dispersion into a metal mold (cuboid mold of 100×100×50mm; the surrounding of the mold is made of pure copper, hollow structure), and then use liquid nitrogen to treat the surrounding metal The frame is cooled, and the flow rate of liquid nitrogen is 0.5L / min;

[0034] 3) freeze-drying: put the mixture of graphene oxide and water prepared in step 2) into a freeze dryer and...

Embodiment 2

[0041] The construction method of the high-strength and high-thermal conductivity three-dimensional graphene heat dissipation material described in this embodiment is specifically carried out according to the following steps:

[0042] 1) Preparation of graphene oxide dispersion: disperse single-layer graphene oxide powder with a size of 20 to 30 microns in deionized water, and perform ultrasonic treatment for 30 minutes at a frequency of 100KHz to form a uniform solution and obtain a concentration of 5mg / mL of graphene oxide dispersion;

[0043] 2) Highly oriented treatment of graphene oxide: put the graphene oxide dispersion into a metal mold (100×100×50mm cuboid mold; the surrounding of the mold is made of pure copper, hollow structure), and then use liquid nitrogen to treat the surrounding metal The frame is cooled, and the rate of passing liquid nitrogen is 0.5L / min;

[0044] 3) freeze-drying: put the mixture of graphene oxide and water prepared in step 2) into a freeze ...

Embodiment 3

[0050] The construction method of the high-strength and high-thermal conductivity three-dimensional graphene heat dissipation material described in this embodiment is specifically carried out according to the following steps:

[0051] 1) Preparation of graphene oxide dispersion: disperse single-layer graphene oxide powder with a size of 20 to 30 microns in deionized water, and perform ultrasonic treatment for 45 minutes at a frequency of 50KHz to form a uniform solution and obtain a concentration of 3mg / mL of graphene oxide dispersion;

[0052] 2) High orientation treatment of graphene oxide: Put the graphene oxide dispersion liquid into a metal mold (cuboid mold of 100×100×50mm; the surrounding of the mold is made of pure copper, hollow structure), and then pass through the air inlet hole on the mold Pass liquid nitrogen to cool the surrounding metal frame;

[0053] 3) Freeze-drying: put the mixture of graphene oxide and water prepared in step 2) into a freeze dryer and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com