Movable bed catalyst for alkylation of toluene and methanol to produce paraxylene and low-carbon olefin

A technology for p-xylene and low-carbon olefins, which is applied in the field of highly selective production of p-xylene and low-carbon olefins fluidized bed catalysts by alkylation of toluene and methanol, and can solve problems such as complex operation and catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (preparation Mg-HZSM-5 fluidized catalyst)

[0036] The ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =61) Calcination at 550°C to remove template agent, exchange with ammonium nitrate solution 4 times in 80°C water bath, after exchange, roast at 550°C for 3 hours to obtain HZSM-5 zeolite molecular sieve.

[0037] Use metal salt to modify HZSM-5 zeolite molecular sieve, the steps are respectively:

[0038] (1) HZSM-5 zeolite molecular sieve 10kg, 9% Mg (MgCl 2 ·6H 2 O) impregnated overnight, after drying, roasting at 550°C for 3 hours to obtain Mg-HZSM-5 zeolite molecular sieve;

[0039] (2) Mix the Mg-HZSM-5 zeolite molecular sieve obtained in step 1 with a silicon or aluminum binder and spray dry it into shape: 40% Mg-HZSM-5 (dry basis)+20% Al 2 o 3 (pseudoboehmite)+40%Al 2 o 3 (aluminum sol) + appropriate amount of bio-glue, beating, rubber milling, defoaming, spray-drying and molding, the particle size distribution of the catalyst is ...

Embodiment 2

[0041] Embodiment 2 (preparation Ca-HZSM-5 fluidized catalyst)

[0042] (1) HZSM-5 zeolite molecular sieve 10kg, 9% Ca (CaCl 2 ) impregnated overnight, after drying, roasting at 550°C for 3 hours to obtain Ca-HZSM-5 zeolite molecular sieve;

[0043] (2) Mix the Ca-HZSM-5 zeolite molecular sieve obtained in step 1 with a silicon or aluminum binder and spray dry it into shape: 40% Ca-HZSM-5 (dry basis)+20% Al 2 o 3 (Pseudoboehmite) + 40% kaolin + appropriate amount of biological glue, beating, rubber milling, defoaming, spray drying and molding, the particle size distribution of the catalyst is 20-100 μm, roasting in a muffle furnace at 550°C for 3 hours, and the catalyst wear index is 1.2 , to obtain microspherical Ca-HZSM-5 fluidized catalyst;

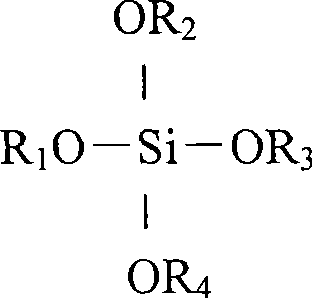

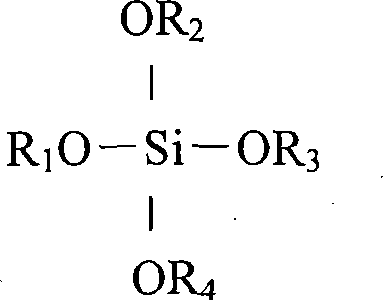

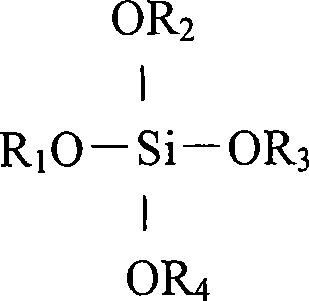

[0044] (3) Using the siloxane reagent tetraethyl silicate to modify the surface of the Ca-ZSM-5 fluidized catalyst obtained in step 2. The steps are as follows: put 5 kg of Ca-HZSM-5 microsphere catalyst into 5 kg of tetraethyl sil...

Embodiment 3

[0045] Embodiment 3 (preparation P-HZSM-5 fluidized catalyst)

[0046] (1) HZSM-5 zeolite molecular sieve 20kg, 3% P(H 3 PO 4 ) impregnated overnight, dried, and roasted at 550°C for 3 hours to obtain P-HZSM-5 zeolite molecular sieve;

[0047] (2) Mix 5kg P-HZSM-5 zeolite molecular sieve with silicon or aluminum binder for spray drying molding, the steps are: 40% P-HZSM-5 (dry basis) + 20% Al 2 o 3 (pseudoboehmite)+40% SiO 2 (silica sol) + appropriate amount of bio-glue, beating, rubber milling, defoaming, spray-drying and molding, the catalyst particle size distribution is 20-100 μm, roasting in a muffle furnace at 550 ° C for 3 hours, the catalyst wear index is 1.8, and microspherical P- HZSM-5 fluidized catalyst;

[0048] (3) Use the siloxane reagent tetraethyl silicate to modify the surface of the P-ZSM-5 fluidized catalyst obtained in step 2. The steps are respectively: put 5kg P-HZSM-5 microsphere catalyst into 5kg tetraethyl silicate Immerse in ethyl ester overnig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com