Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

A technology for aromatics and propylene, which is applied in the field of co-production of aromatics and propylene from methanol/dimethyl ether, can solve the problems of high cost of separating ethylene, low content, difficult application and promotion, etc., so as to reduce production investment, reduce separation difficulty, and improve economic efficiency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

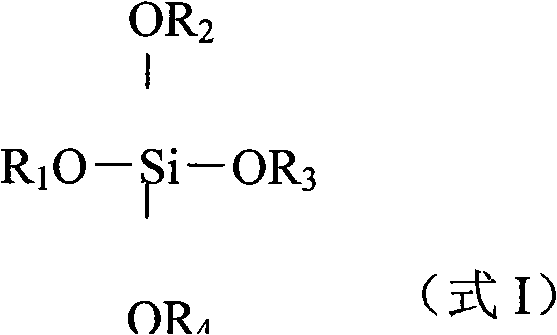

[0029] In the method for the simultaneous co-production of propylene for the preparation of aromatics provided by the present invention, the catalyst in the first reactor adopts a zeolite molecular sieve catalyst jointly modified by metal and silanization. Alkyl compounds modify the surface acidity and pore structure, so as to obtain a catalyst for the preparation of p-xylene with high selectivity for the conversion of methanol / dimethyl ether, and co-produce low-carbon olefins such as ethylene propylene. The catalyst in the second reactor adopts metal-modified zeolite molecular sieve catalyst.

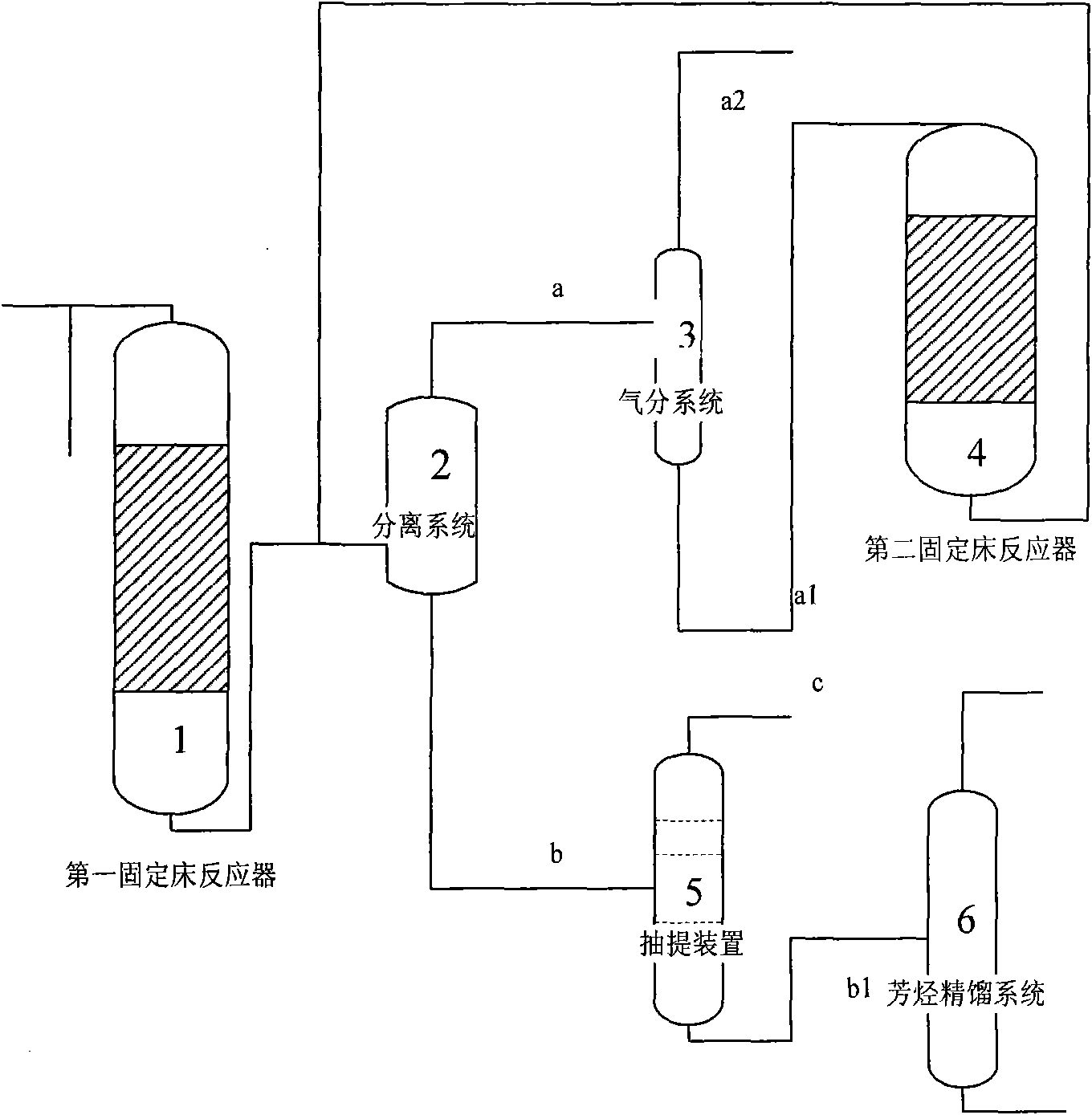

[0030] The method for the simultaneous co-production of propylene in the preparation of aromatics provided by the invention, its technological process schematic diagram is as follows figure 1 shown, wherein, a is a mixed hydrocarbon with carbon number less than or equal to 4; a 1 For mixed hydrocarbons; a2 is propylene; b is a mixture of aromatic hydrocarbons; b 1 is aromatic mixture...

Embodiment 1

[0034] 1) Preparation of modified zeolite molecular sieve catalyst

[0035] The original powder of ZSM-5 zeolite molecular sieve (purchased from Catalyst Factory of Nankai University) (SiO 2 / Al 2 o 3 =50) Roasting at 550° C. to remove template agent, exchange with ammonium nitrate solution 4 times in 80° C. water bath, dry in air at 120° C. after exchange, and roast at 550° C. for 3 hours to obtain HZSM-5 zeolite molecular sieve.

[0036] a. Preparation of catalyst MTA-06

[0037] 20g of the above-mentioned HZSM-5 zeolite molecular sieves were pressed into tablets, and a 40-60 mesh sample was obtained after crushing and screening, and zinc nitrate [Zn(NO 3 ) 2 ·6H 2 O] solution at room temperature for 4 hours, after drying at 120°C and roasting in air at 550°C for 6 hours; use orthoethyl silicate (TEOS) to impregnate zinc-modified HZSM-5 zeolite molecular sieve at room temperature for 24 hours, and pour out the upper liquid After drying at 120° C. and roasting in air at...

Embodiment 2

[0054] 1) Preparation of modified zeolite molecular sieve catalyst

[0055] The original powder of ZSM-5 zeolite molecular sieve (purchased from Catalyst Factory of Nankai University) (SiO 2 / Al 2 o 3 =50) Roasting at 550° C. to remove template agent, exchange with ammonium nitrate solution 4 times in 80° C. water bath, dry in air at 120° C. after exchange, and roast at 550° C. for 3 hours to obtain HZSM-5 zeolite molecular sieve.

[0056] a. Preparation of catalyst MTA-07

[0057] 20g of the above-mentioned HZSM-5 zeolite molecular sieve was pressed into tablets, and a 40-60 mesh sample was obtained after crushing and screening, and molybdenum nitrate [Mo(NO 3 ) 3 ·5H 2 O] The solution was impregnated with HZSM-5 molecular sieve at room temperature for 4 hours, dried at 120°C and then calcined in air at 550°C for 6 hours. The molybdenum-modified HZSM-5 zeolite molecular sieve was impregnated with tetraethyl orthosilicate (TEOS) at room temperature for 24 hours. After po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com