Method for preparing ethylene and propylene and co-producing p-xylene through methanol/dimethyl ether conversion

A technology of p-xylene and ethylene propylene, applied in the field of producing low-carbon olefins and aromatics, which can solve the problems of poor selectivity of ethylene propylene, low market value of mixed aromatics, difficulty in application and promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 fixed-bed catalyst preparation

[0029] 1) 500g ZSM-5 zeolite molecular sieve former powder (Nankai University Catalyst Factory) (SiO 2 / Al 2 o 3 =50) Roast at 550°C to remove template agent, exchange 4 times with 0.5 molar equivalent ammonium nitrate solution in 80°C water bath, dry in air at 120°C after exchange, and roast at 550°C for 3 hours to obtain HZSM-5 Zeolite molecular sieve.

[0030] 2) Take 20 g of the HZSM-5 zeolite molecular sieve prepared in step 1), impregnate it with tetraethyl orthosilicate (TEOS) at room temperature for 24 hours, pour out the upper liquid, dry it at 120°C, and roast it in air at 550°C for 6 hours to obtain a silanized modified zeolite. The permanent HZSM-5 catalyst is named MTOA-1.

Embodiment 2

[0031] Example 2 Fluidized bed catalyst preparation.

[0032] 1) Take 200 g of the HZSM-5 zeolite molecular sieve prepared in Example 1, impregnate it with tetraethyl orthosilicate (TEOS) at room temperature for 24 hours, pour out the upper liquid, dry it at 120°C, and roast it in the air at 550°C for 6 hours to obtain a silanized modified zeolite. Sexual HZSM-5 zeolite molecular sieve.

[0033] 2) Mix the modified HZSM-5 zeolite molecular sieve with kaolin, silica sol, aluminum sol and deionized water to form a slurry, and the dry basis mass ratio of molecular sieve to kaolin, silica sol and aluminum sol is 30:32:26:12 , The solid content of the slurry is about 35wt%. The slurry is aged at room temperature for 5 hours, passed through a colloid mill film, and then sprayed to form a microsphere catalyst with a particle size of 20-100 μm. The catalyst was named MTOA-2.

Embodiment 3

[0034] Embodiment 3 fixed bed reaction evaluation

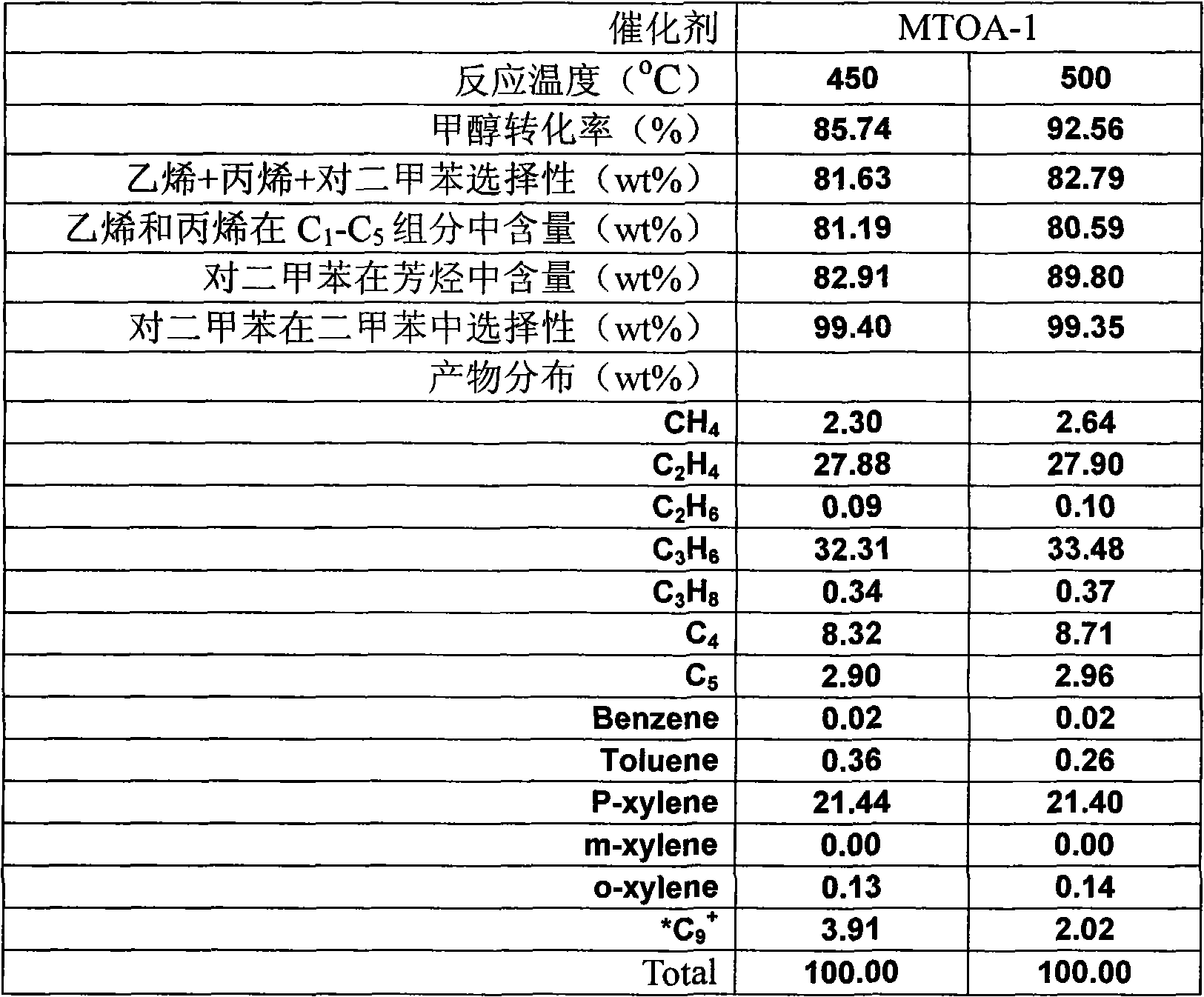

[0035]The MTOA-1 catalyst prepared in Example 1 was used as the reaction catalyst, pressed into tablets, crushed and sieved to 40-60 meshes. 5g of catalysts were respectively loaded into a fixed bed reactor, treated in an air atmosphere at 550°C for 1 hour, and cooled down to reaction temperatures of 450°C and 500°C in a nitrogen atmosphere. Methanol is pumped into the reactor through a feed pump to contact and react with the catalyst. The raw material methanol feed weight space velocity is 2h -1 , The reaction product was analyzed online by Varian3800 gas chromatography, and the reaction results are shown in Table 1.

[0036] Under different reaction temperatures, the total selectivity of ethylene, propylene and p-xylene in the product (remove generated water) is 81.63wt% and 82.79wt% respectively, and ethylene and propylene are at C 1 -C 5 The contents of the components are 81.19wt% and 80.59wt%, the contents of p-xylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com