Automatic washing and precipitating pool

An automatic cleaning and sedimentation tank technology, applied in the direction of sedimentation separation, sedimentation tank, chemical instruments and methods, etc., can solve the problems of inconvenient modern management, the inconvenience of sedimentation, the effect of lowering the bottom sedimentation tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

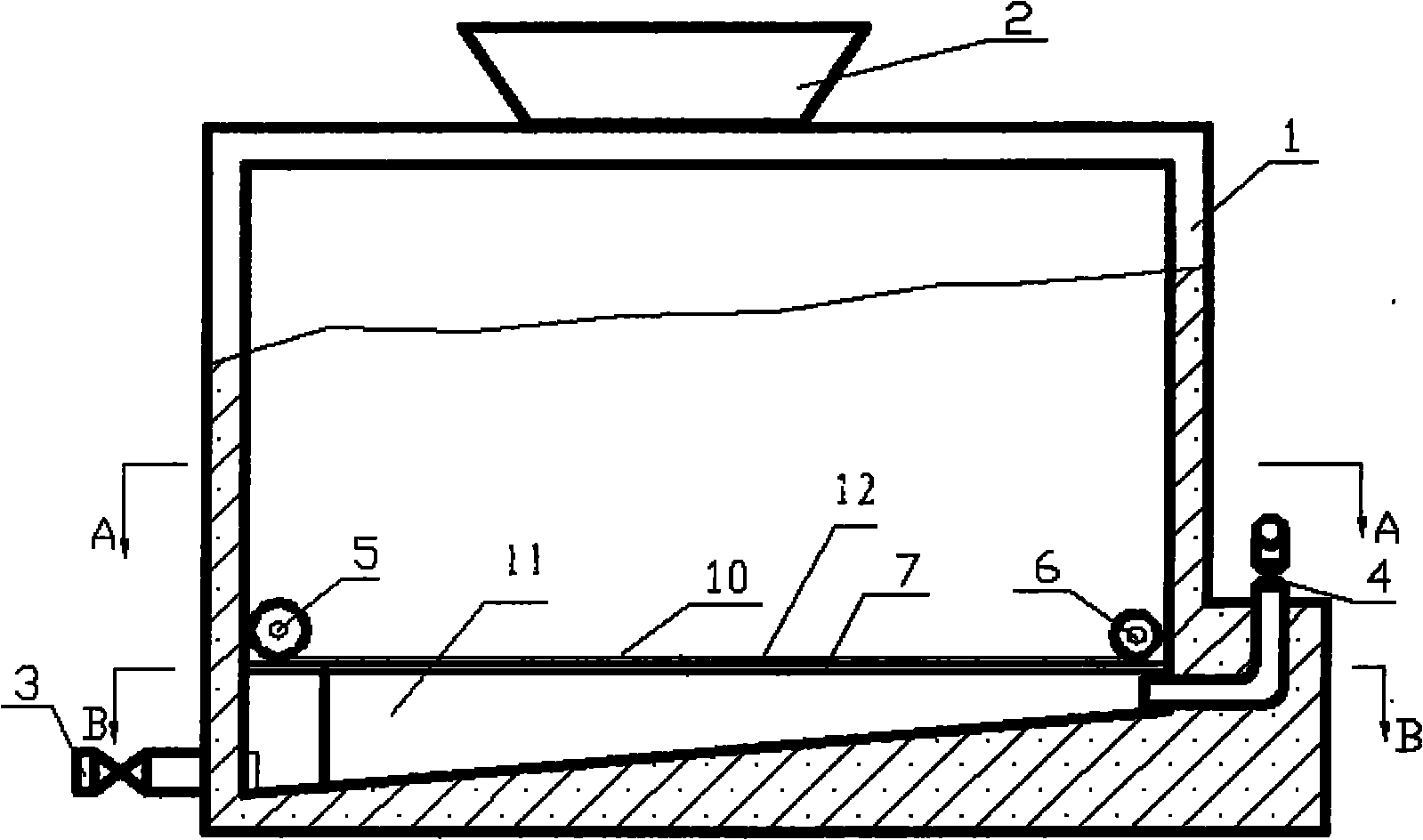

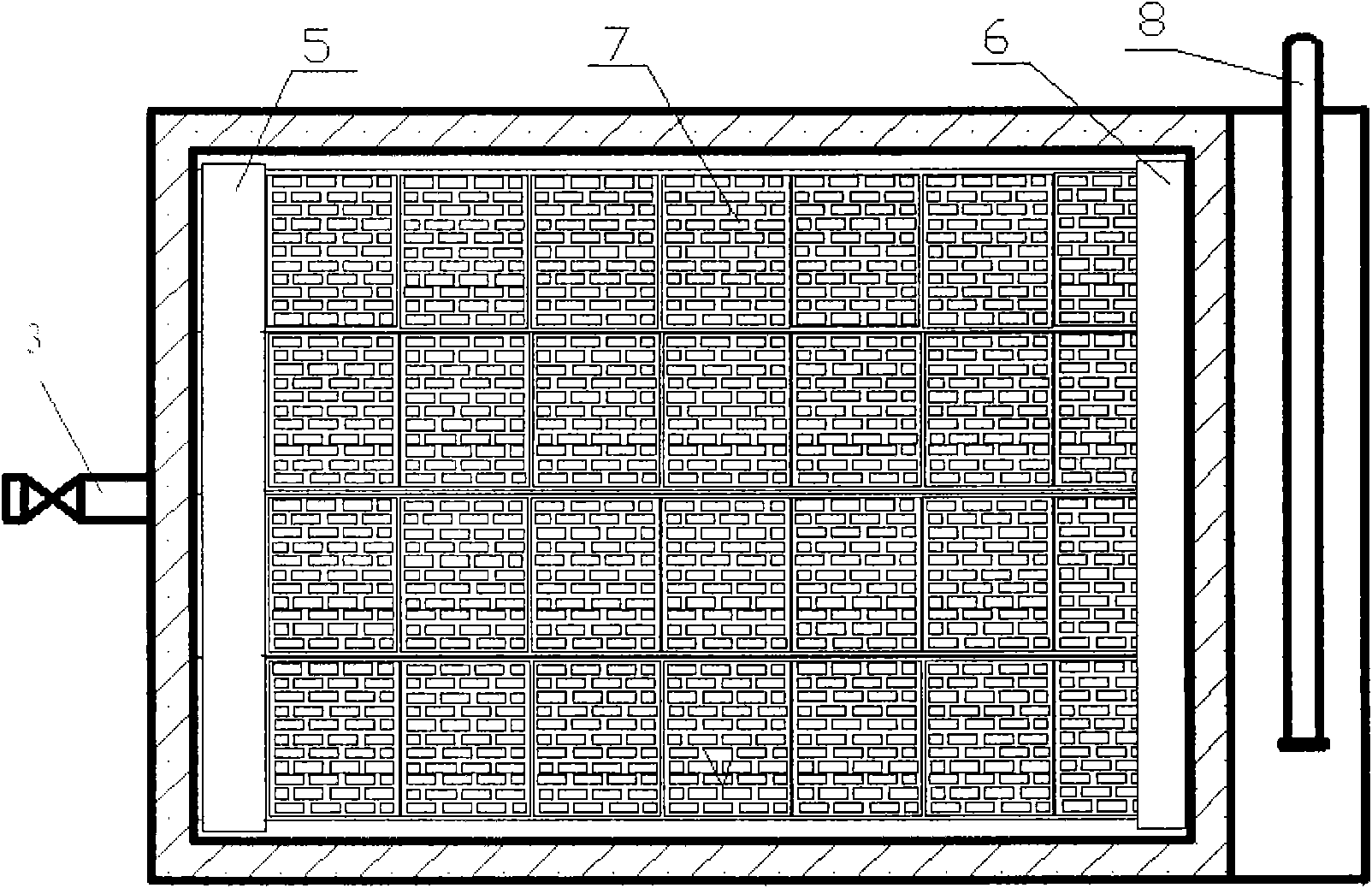

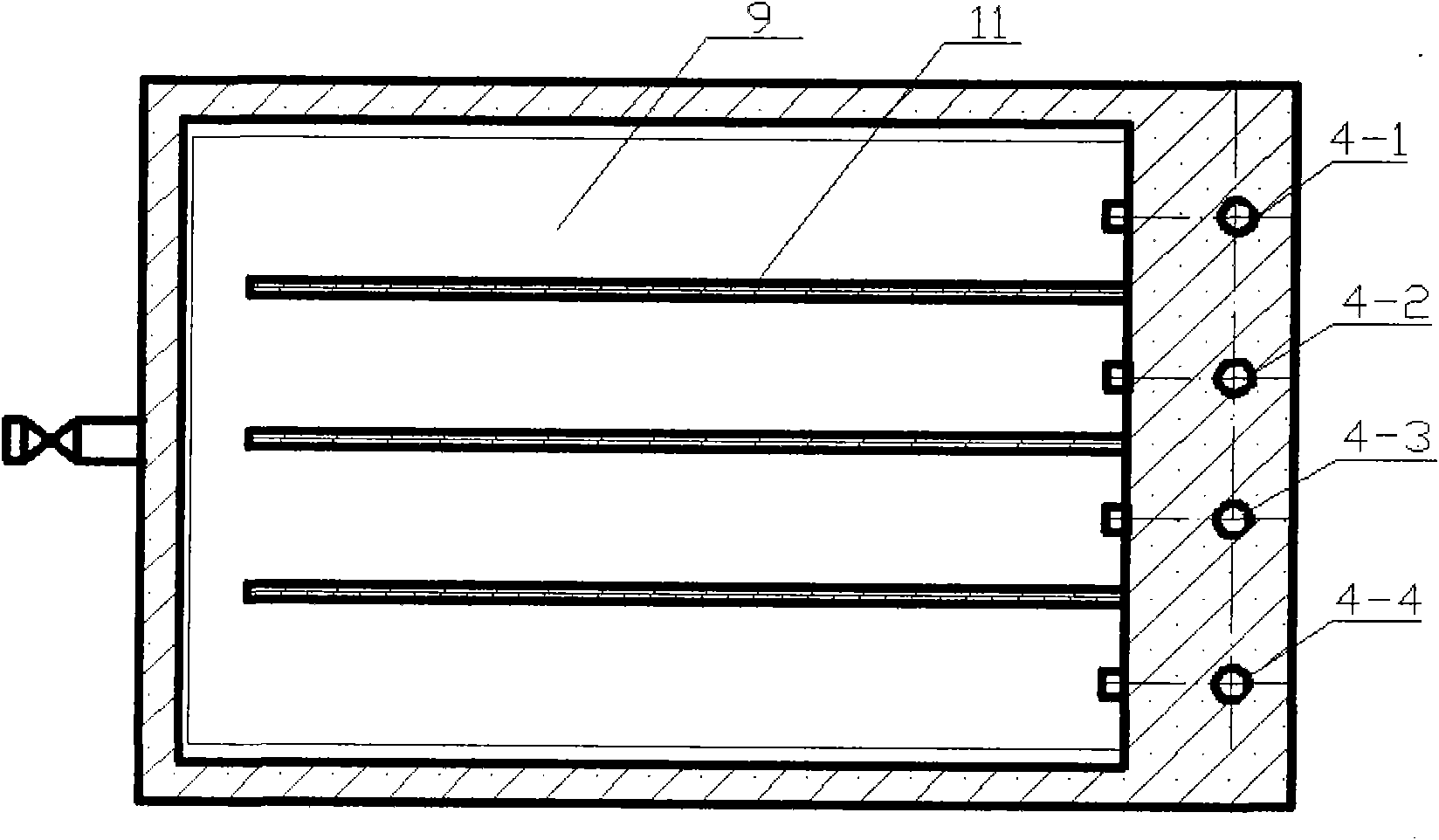

[0014] Such as figure 1 As shown, a cooling tower 2 is arranged on the pool body 1, and the bottom of the pool body 1 is a sloped pool bottom. In the drawings of this embodiment, the bottom of the pool is low on the left and high on the right; Sewage pipeline 3 is located at the bottom of the pool and is the low end of the inclined plane. The bottom of the pool is provided with a dividing plate 11 along the slope direction at the bottom of the pool, which will divide the bottom of the pool into at least two cleaning sedimentation tanks 9, such as image 3 As shown, in this embodiment, three partitions 11 are arranged at intervals at the bottom of the pool, and the bottom of the pool is divided into four cleaning and sedimentation tanks 9; each cleaning and sedimentation tank is connected to the flushing pipeline, and the flushing pipeline 4 is provided with four Branch pipes, flushing valves 4-1, 4-2, 4-3 and 4-4 are arranged on each branch pipe; four cleaning and sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com