Equipment having live line water washing and deicing operation functions for power transmission system and application method of equipment

A technology for power transmission systems and operating equipment, applied to overhead line/cable equipment, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problem of rapid temperature drop of flushing water, difficulty in achieving the expected deicing effect, and unsatisfactory Deicing water temperature requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

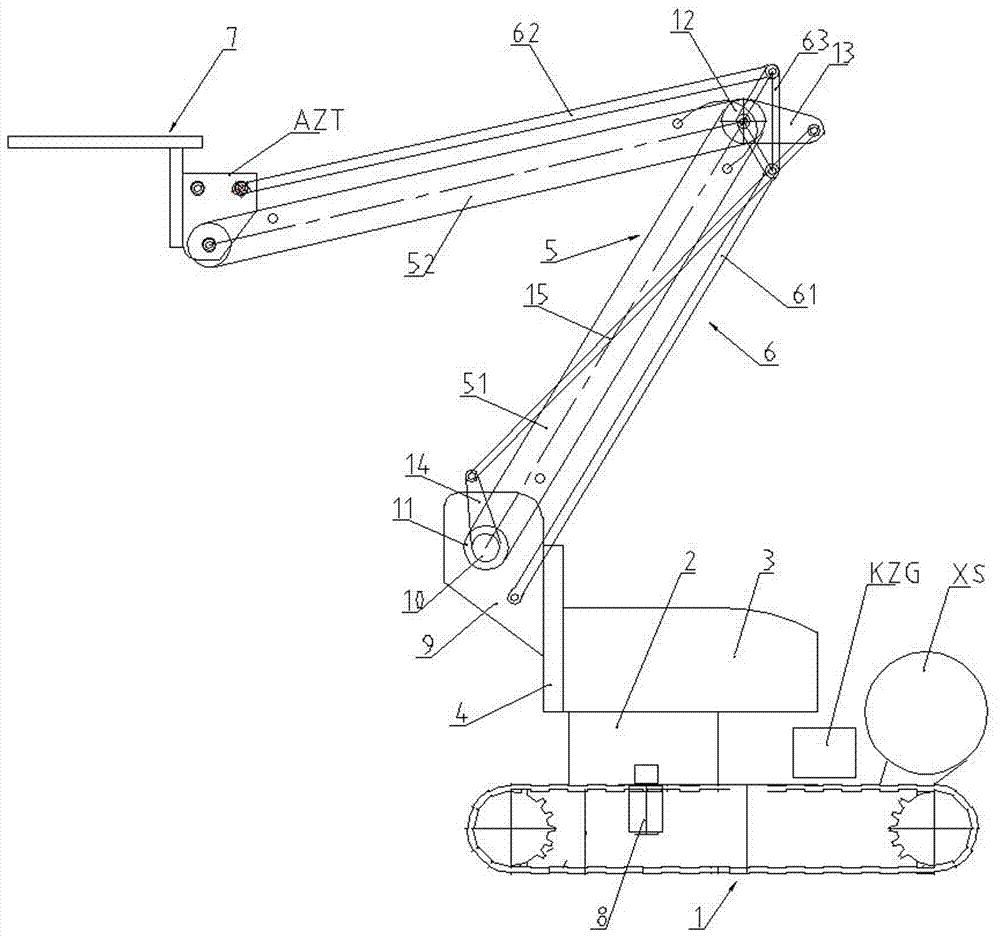

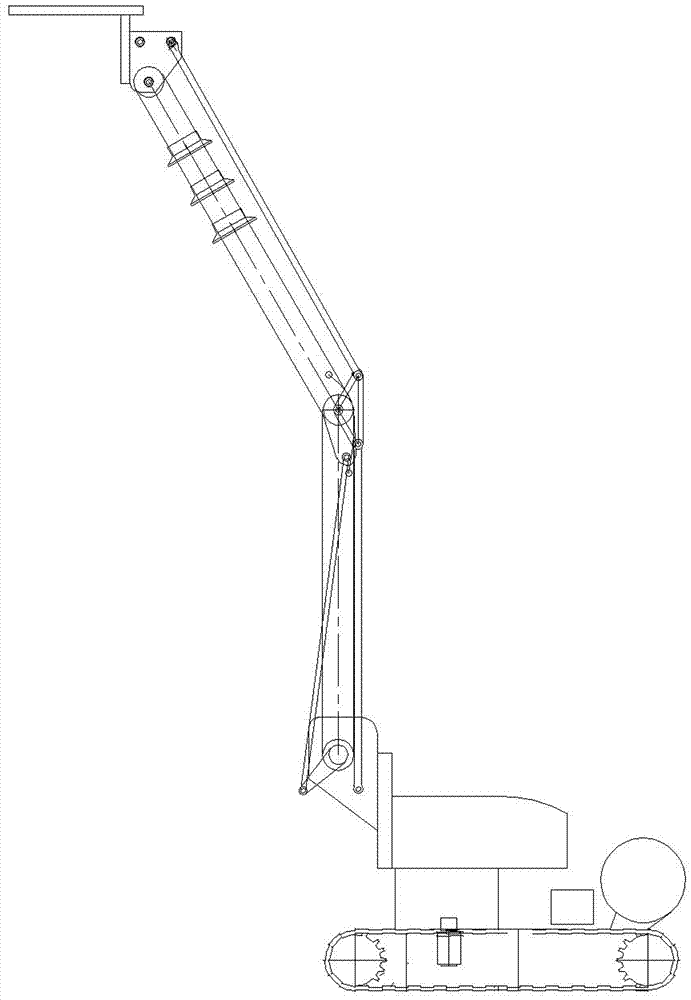

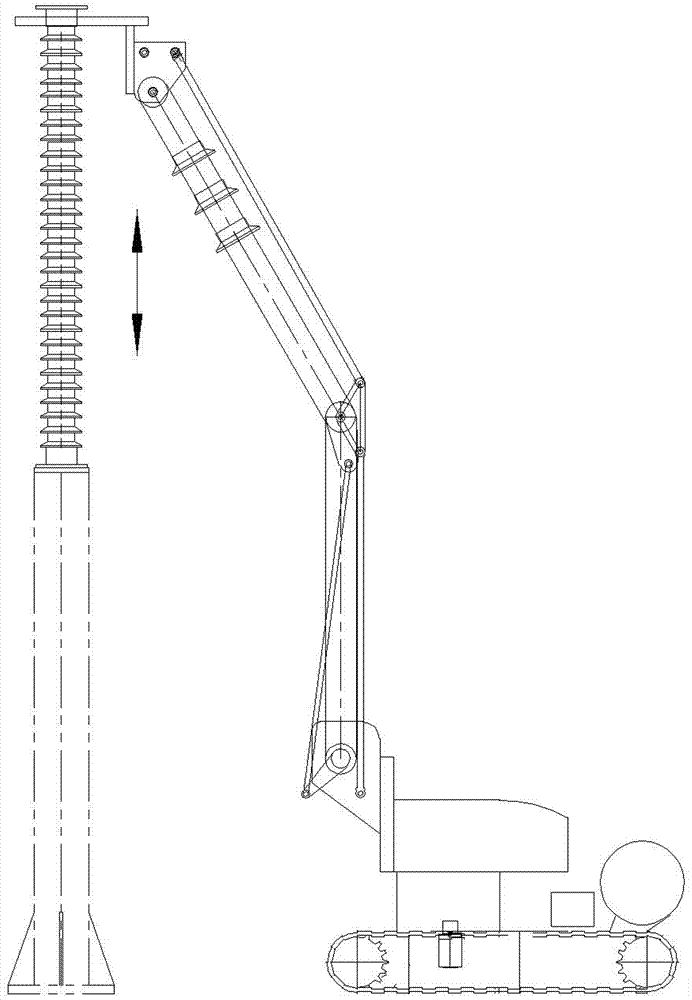

[0037] Such as Figure 1 to Figure 4As shown, the power transmission system provided by the present invention uses electrified water flushing and deicing equipment for cleaning post insulators of substations. It includes a crawler chassis 1, a rotary support 2, a horizontal rotary table 3, a vertical rotary table 4, an insulating working arm 5, a posture maintaining mechanism 6, and a cleaning device 7.

[0038] The slewing support 2 is connected to the upper end of the crawler chassis 1, and the pure water storage tank SX and the control cabinet KZG are also connected to the crawler chassis 1.

[0039] The horizontal rotary table 3 is driven by a rotary servo motor 8 to perform its horizontal rotary motion.

[0040] The vertical turntable 4 is connected to one side of the three horizontal turntables by the mounting base 9. Both sides of the mounting base 9 are respectively arranged with a boom driving reduction motor 11 and a small arm driving reduction motor servo motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com