Preparation method of spherical 304 stainless steel powder

A technology of 304 stainless steel and spherical powder, which is applied in the field of preparation of 304 stainless steel spherical powder, can solve problems such as difficult removal of scale, achieve high sphericity, increase powder yield, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

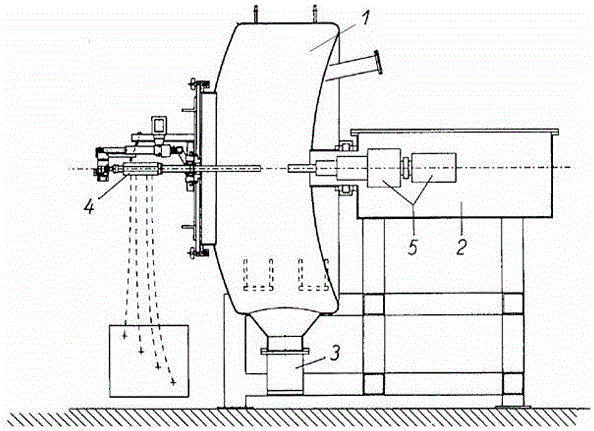

Image

Examples

Embodiment 1

[0023] The preparation method of 304 stainless steel spherical powders, comprises the following steps:

[0024] 1) According to the ingredients required for 304 stainless steel, the raw materials for melting and casting are obtained according to the mass percentage, Cr: 19.00%, Si: 1.00%, S: 0.03%, C: 0.08%, P: 0.045%, Mn: 2.00%, Ni: 8.00%, the rest is Fe, and the casting raw materials are smelted to obtain stainless steel ingots; 304 stainless steel ingots are made into forged bars with a microstructure density of 99.0% by forging process;

[0025] 2) Carry out fine turning processing on the forged bar. The processed electrode rod is: 75mm in diameter, 650mm in length, 0.003mm in roundness deviation, 0.05mm / 650mm in straightness deviation, and 0.899μm in roughness;

[0026] 3) Place the obtained electrode rod in the electrode rod installation chamber 2, and evacuate the atomization chamber 1 until the vacuum degree of the equipment reaches 1×10 -3 Pa filled with inert gas, ...

Embodiment 2

[0031] The preparation method of 304 stainless steel spherical powders, comprises the following steps:

[0032] 1) According to the ingredients required for 304 stainless steel, the raw materials for melting and casting are obtained according to the mass percentage, C: 0.07%, Mn: 2.00%, P: 0.045%, Si: 0.75%, Cr: 18.00%, Ni: 8.00%, and the rest For Fe, the stainless steel ingot is obtained through the melting process; through forging, the 304 stainless steel ingot is made into a forged bar with a dense structure;

[0033] 2) The forged bar is machined by a lathe and a precision CNC lathe to obtain a stainless steel electrode rod that meets the requirements of the plasma rotating electrode method. The diameter of the stainless steel electrode rod is 80mm, the length is 700mm, the roundness deviation is 0.01mm, and the straightness deviation 0.025mm / 700mm, roughness 1.0μm;

[0034] 3) Place the obtained electrode rod in the electrode rod installation room, and evacuate the atomi...

Embodiment 3

[0041] The preparation method of 304 stainless steel spherical powders, comprises the following steps:

[0042] 1) According to the ingredients required for 304 stainless steel, according to the mass percentage, the casting raw materials are obtained, C: 0.08%, Mn: 2.00%, P: 0.045%, S: 0.03%, Si: 1.00%, Cr: 20.00%, Ni : 8.00%, Cu: 1.00%, N: 0.10%, the rest is Fe, and the stainless steel ingot is obtained through the melting process; through forging, the 304 stainless steel ingot is made into a forged bar with a dense structure;

[0043] 2) The forged bar is machined by a lathe and a precision CNC lathe to obtain a stainless steel electrode rod that meets the requirements of the plasma rotating electrode method. The diameter of the stainless steel electrode rod is 50mm, the length is 200mm, the roundness deviation is 0.05mm, and the straightness deviation 0.1mm / 200mm, roughness 0.8μm;

[0044] 3) Place the obtained electrode rod in the electrode rod installation room, and evac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com