Method for preparing reduced titanium powder by multi-stage deep reduction

A deep and titanium powder technology, which is applied in the field of multi-stage deep reduction to prepare reduced titanium powder, can solve the problems of great influence on the performance of titanium powder and high cost, and achieve controllable particle size distribution, low equipment requirements, process conditions and equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

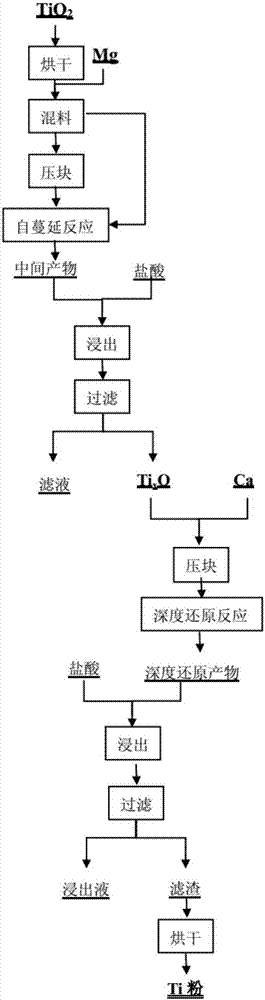

[0054] A method for preparing reduced titanium powder through multi-stage deep reduction is carried out in the following steps:

[0055] Step 1, self-propagating reaction

[0056] Put the titanium dioxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried titanium dioxide powder; mix the dried titanium dioxide powder and magnesium powder evenly to obtain a mixed material; press the mixed material at 20MPa to obtain Block billet, put the block billet of the mixed material into the self-propagating reaction furnace, and initiate the self-propagating reaction by partial ignition. The temperature is controlled at 500 ° C. After the reaction material is cooled, the low-valent titanium oxide Ti is obtained. x The intermediate product of O dispersed in the MgO matrix; where, by molar ratio, TiO 2 : Mg=1:1, low-valent titanium oxide Ti x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric low-valent titanium oxides, and...

Embodiment 2

[0070] A method for preparing reduced titanium powder through multi-stage deep reduction is carried out in the following steps:

[0071] Step 1, self-propagating reaction

[0072] Put the titanium dioxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried titanium dioxide powder; mix the dried titanium dioxide powder and magnesium powder evenly to obtain a mixed material; press the mixed material at 40MPa to obtain Block billet, put the block billet of the mixed material into the self-propagating reaction furnace, and initiate the self-propagating reaction by means of partial ignition. The temperature is controlled at 600 ° C. After the reaction material is cooled, the low-valent titanium oxide Ti is obtained. x The intermediate product of O dispersed in the MgO matrix; where, by molar ratio, TiO 2 : Mg=1:1.2, low-valent titanium oxide Ti x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric low-valent titanium ...

Embodiment 3

[0086] A method for preparing reduced titanium powder through multi-stage deep reduction is carried out in the following steps:

[0087] Step 1, self-propagating reaction

[0088]Put the titanium dioxide powder in an oven and dry at 100-150°C for 24 hours to obtain the dried titanium dioxide powder; mix the dried titanium dioxide powder and magnesium powder evenly to obtain a mixed material; press the mixed material at 60MPa to obtain Block billet, put the block billet of the mixed material into the self-propagating reaction furnace, and initiate the self-propagating reaction by partial ignition. The temperature is controlled at 500 ° C. After the reaction material is cooled, the low-valent titanium oxide Ti is obtained. x The intermediate product of O dispersed in the MgO matrix; where, by molar ratio, TiO 2 :Mg=1:0.8, low-valent titanium oxide Ti x The intermediate product of O dispersed in the MgO matrix is a mixture of non-stoichiometric low-valent titanium oxides, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com