Process for preparing anatase type nano-titanium dioxide

A nano-titanium dioxide, anatase type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low equipment material requirements, low operating temperature, expensive raw materials, etc., and achieve low cost and uniform particle size distribution. , the effect of less raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

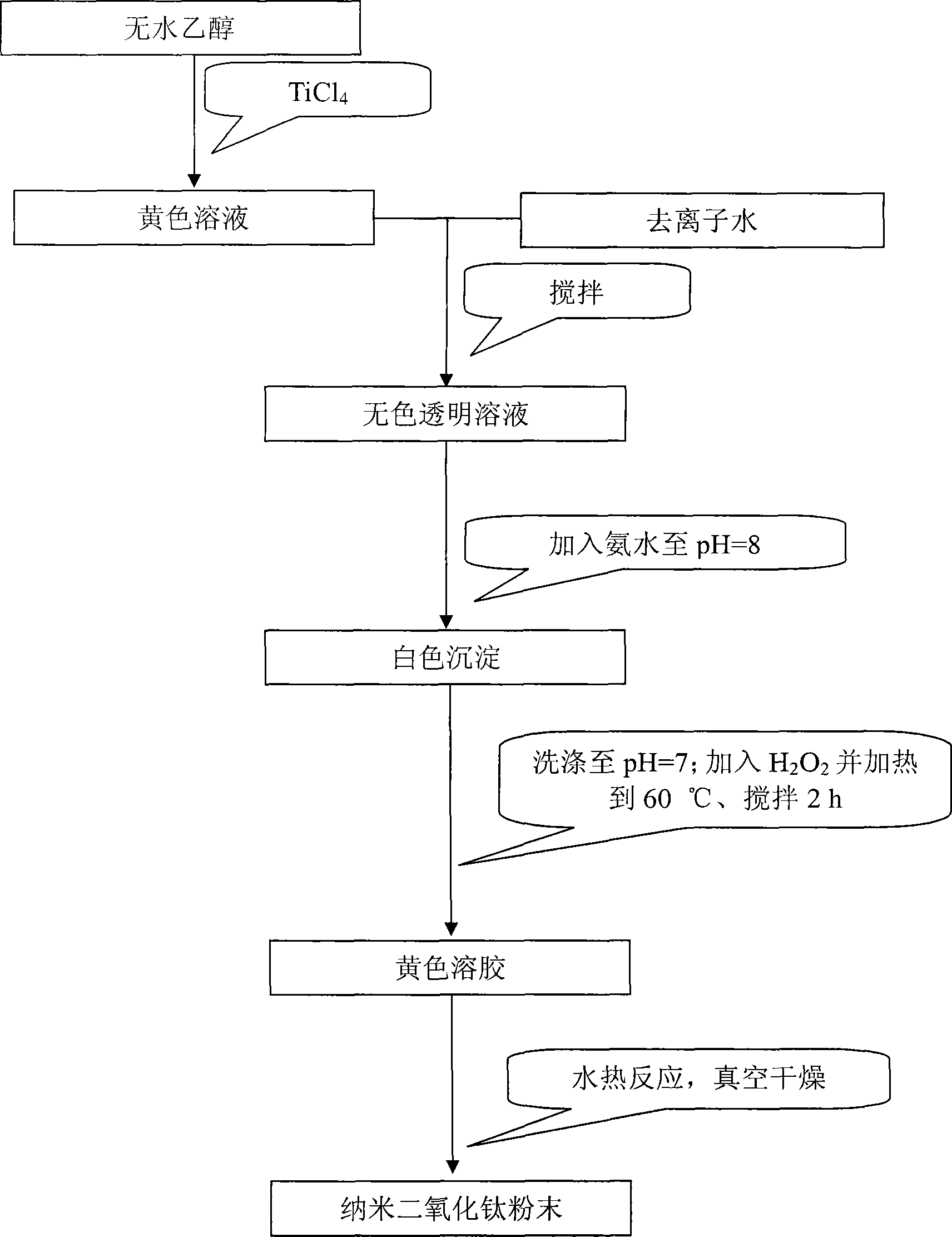

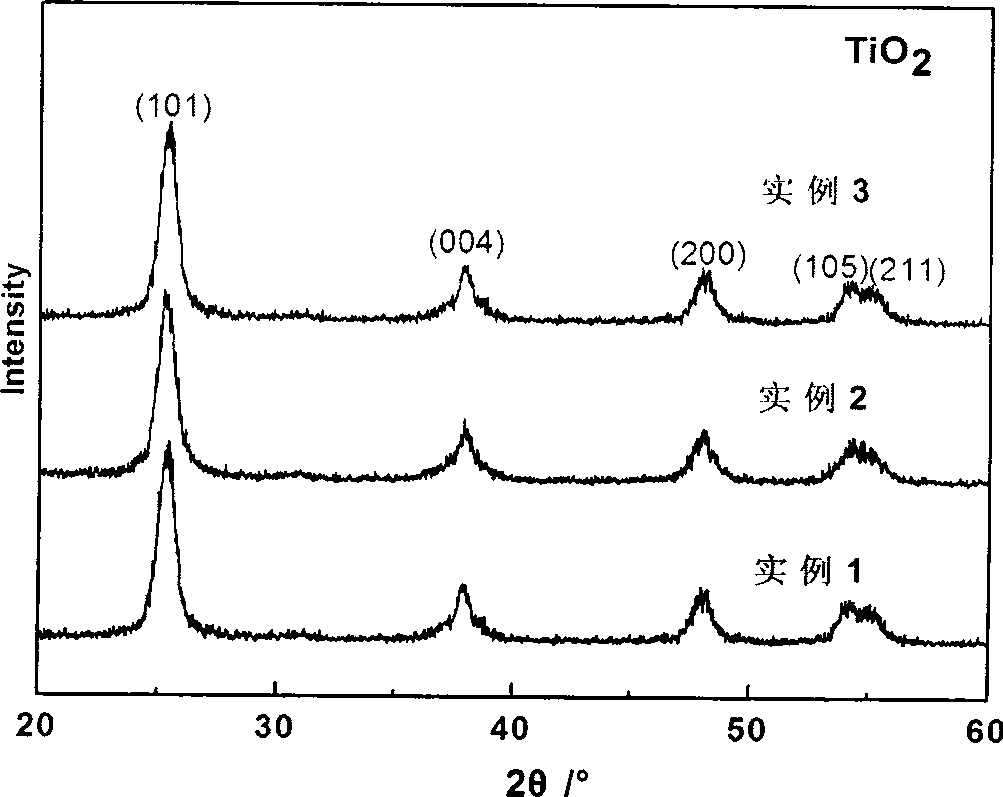

[0029] like figure 1 So, 1) Get 50ml of absolute ethanol and put it into an ice-water bath, add 10ml of TiCl dropwise 4 , a pale yellow solution was obtained. The light yellow solution was vigorously stirred in an ice-water bath for 10 minutes, then 50 ml of deionized water was added to form a colorless transparent solution, and the vigorous stirring was continued for 120 minutes. 2) Then add ρ=0.91×10 3 kg / m 3 ammonia solution to pH = 8 to obtain a white solid; then filtered and washed with deionized water to pH = 7 to obtain an anatase nano-titanium dioxide precursor (white solid). 3) Add 50ml of ρ=1.11×10 to the anatase nano-titanium dioxide precursor 3 kg / m 3 H 2 o 2 , Stirring at 60°C for 2h, a yellow sol was obtained. Transfer the yellow sol into a polytetrafluoroethylene-lined reactor for hydrothermal treatment at 140°C for 2 hours, and vacuum-dry at 60°C to obtain white anatase-type nano-titanium dioxide powder with high activity and controllable particle size...

Embodiment 2

[0031] 1) Take 200ml of absolute ethanol and put it in an ice water bath, add 10ml of TiCl dropwise 4 , a pale yellow solution was obtained. The light yellow solution was vigorously stirred in an ice-water bath for 60 minutes, then 300 ml of deionized water was added to form a colorless transparent solution, and the vigorous stirring was continued for 10 minutes. 2) Then add ρ=0.91×10 3 kg / m 3 ammonia solution to pH = 8 to obtain a white solid, which was then filtered and washed with deionized water until pH = 7 to obtain an anatase-type nano-titanium dioxide precursor (white solid). 3) Add 200ml of ρ=1.11×10 to the anatase nano-titanium dioxide precursor 3 kg / m 3 H 2 o 2 , Stirring at 60°C for 2h, a yellow sol was obtained. Transfer the yellow sol into a polytetrafluoroethylene-lined reactor for hydrothermal treatment at 180°C for 8 hours, and vacuum-dry at 60°C to obtain white anatase-type nano-titanium dioxide powder with high activity and controllable particle size....

Embodiment 3

[0033] 1) Take 100ml of absolute ethanol and put it in an ice-water bath, add 10ml of TiCl dropwise 4 , a pale yellow solution was obtained. The light yellow solution was vigorously stirred in an ice-water bath for 40 minutes, then 150 ml of deionized water was added to form a colorless transparent solution, and the vigorous stirring was continued for 90 minutes. 2) Then add ρ=0.91×10 3 kg / m 3 ammonia solution to pH = 8 to obtain a white solid, which was then filtered and washed with deionized water until pH = 7 to obtain an anatase-type nano-titanium dioxide precursor (white solid). 3) Add 100ml of ρ=1.11×10 to the anatase nano-titanium dioxide precursor 3 kg / m 3 H 2 o 2 , Stirring at 60°C for 2h, a yellow sol was obtained. Transfer the yellow sol into a polytetrafluoroethylene-lined reactor for hydrothermal treatment at 160°C for 4 hours, and vacuum-dry at 60°C to obtain white anatase-type nano-titanium dioxide powder with high activity and controllable particle size....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com