Special temperature-control cooling thermal treatment technology

A temperature-controlled cooling and process technology, applied in the field of heat treatment technology, can solve problems such as affecting the hardness of high-frequency quenching, scrapping workpieces, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

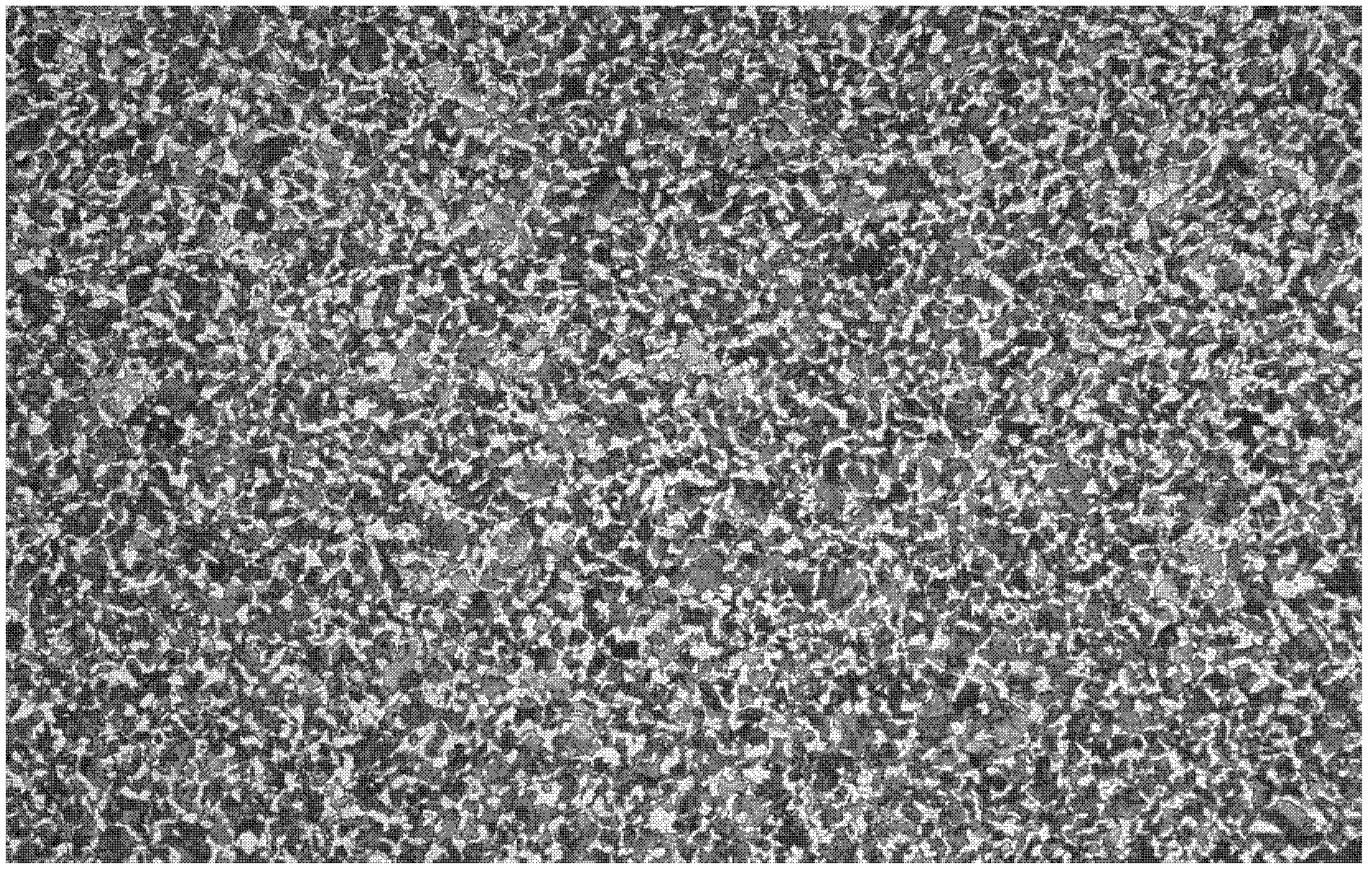

[0018] Place the flange shaft-XC45 warm-forged blank in a continuous mesh belt temperature-controlled furnace, and change the structure in a constant temperature environment by controlling the temperature in the furnace. The heating zone of the temperature control furnace is divided into four zones, the temperature of the first zone and the second zone is 630-680°C, the temperature of the third zone is 590-630°C, the temperature of the fourth zone is not more than 560°C, and the speed of the variable frequency motor of the mesh belt is 10±4Hz---that is, the time for the workpiece to pass through the entire belt is 75-90min. Enter the slow cooling zone until it is released at 500°C.

[0019] The hardness of the temperature-controlled forging blank is 196-211HB, and the hardness dispersion of a single piece is less than 10HB, and the hardness dispersion of the batch is less than 15HB. The metallographic structure is uniform, and the structure is fine pearlite and a small amount ...

Embodiment 2

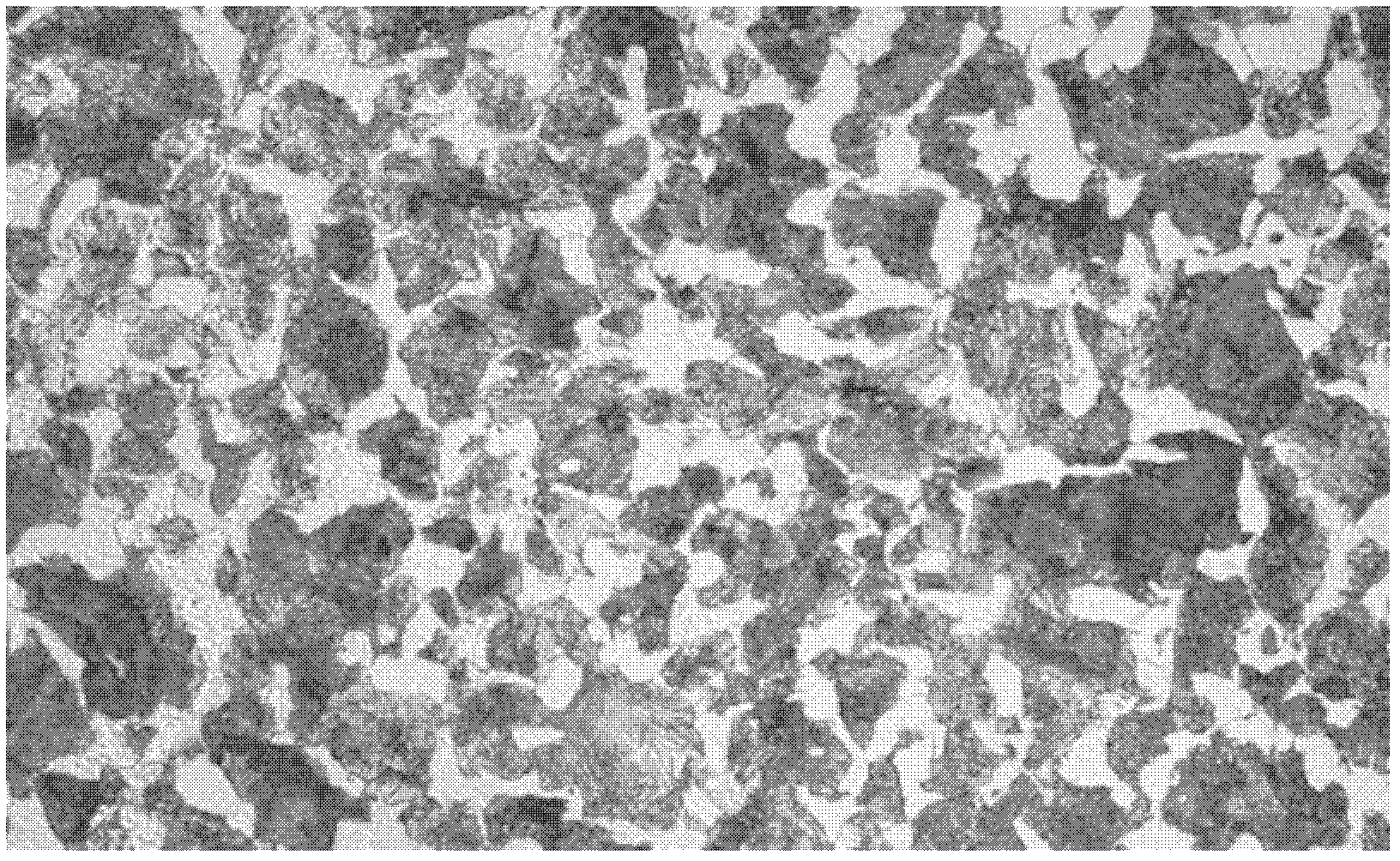

[0021] Put the universal joint-CF53 warm-forged blank in a continuous mesh belt temperature-controlled furnace, and change the structure in a constant temperature environment by controlling the temperature in the furnace. The heating zone of the temperature control furnace is divided into four zones, the temperature of the first zone and the second zone is 630-680°C, the temperature of the third zone is 590-630°C, the temperature of the fourth zone is not more than 560°C, and the speed of the variable frequency motor of the mesh belt is 10±4Hz---that is, the time for the workpiece to pass through the entire belt is 75-90min. Enter the slow cooling zone until it is released at 500°C.

[0022] The hardness of the temperature-controlled forging blank is 208-225HB, and the hardness dispersion of a single piece is less than 10HB, and the hardness dispersion of the batch is less than 17HB. The metallographic structure is uniform, and the structure is fine pearlite and a small amount...

Embodiment 3

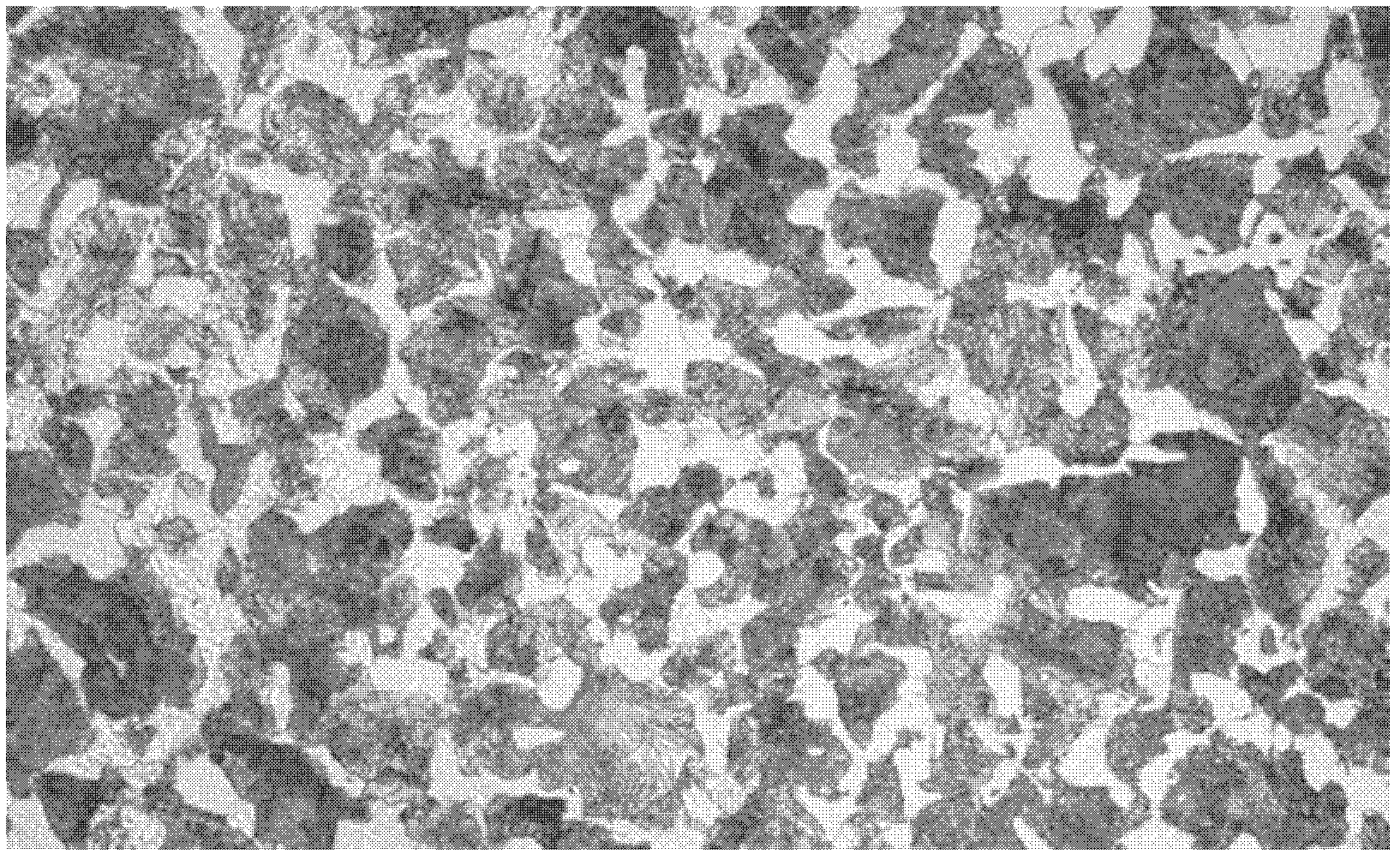

[0024] Put the flange shaft-XC45 warm-forged blank in a continuous mesh belt temperature-controlled furnace, and control the temperature in the furnace to transform the structure in a constant temperature environment. The temperature in the first and second zones of the temperature-controlled furnace is 640- 650°C, the temperature in the third zone is 600-620°C, the temperature in the fourth zone is not more than 550°C, the speed of the variable frequency motor of the mesh belt is 10±4Hz, the time for the workpiece to pass through the entire mesh belt is 80-90min, and enter the slow cooling zone Until it comes out of the furnace at 480°C, the hardness of the temperature-controlled forging blank is 196-211HB, and the hardness dispersion of a single piece is less than 10HB, and the hardness dispersion of the batch is less than 15HB. The metallographic structure is uniform, and the structure is fine pearlite and a small amount. Punctate fine spheroids, small massive ferrite and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com