Method and composition for inhibiting mildew of betel nuts

A composition and a technology of betel nut, applied in the field of inhibiting betel nut mildew, can solve the problems of limited mildew resistance, increase and limitation of betel nut hardness, and achieve the effects of improving mildew resistance, reducing free water, and enhancing softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

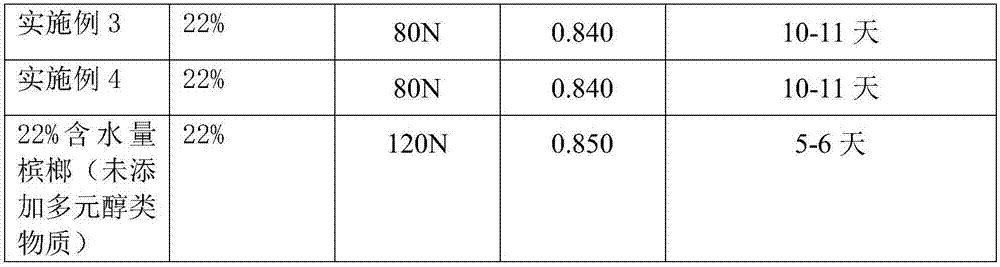

Embodiment 1

[0027] Take 100 parts of betel nut and boil the seeds to make the water content reach 33%. There is no residual water drop in the betel nut fruit. Pour it into the tank, add 6 parts of maltitol, and make it. / 3h; After osmosis, the free water in the betel nut is combined with maltitol, thereby reducing the free water activity of the betel nut by 1.5% to 0.840Aw. After processing such as flakes, the water content of the betel nut is reduced to 22%, and the softness can still reach the softness level of 80N, which is 26% of the water content of the betel nut.

Embodiment 2

[0029] Take 100 parts of betel nut and boil the seeds to make the water content reach 33%. There is no residual water droplet in the betel nut fruit. The temperature in the canning tank is 40°C, and the frequency of the canning is 1r / 3h; after osmosis, the free water in the betel nut is combined with maltitol, thereby reducing the free water activity of the betel nut by 1.5% to 0.840Aw. After roasting, seed pressing, slicing, stewing, and drying, the water content of the betel nut is reduced to 22%, and the softness can still reach the softness level of 80N, which is 26% of the water content of the betel nut.

Embodiment 3

[0031] Take 100 parts of betel nut and boil the seeds to make the water content reach 33%. There is no residual water drop in the betel nut fruit, pour it into the tank, add 1.5 parts of maltitol, 1 part of sorbitol, 1 part of glycerin, and 1.5 parts of xylitol , hair system, control the temperature in the tank to 40°C, and the frequency of the tank transfer to 1r / 3h; after osmosis, the free water in the betel nut is combined with maltitol, thereby reducing the free water activity of the betel nut by 1.5%. Reduced to 0.840Aw, after baking, seed pressing, slicing, stewing, and drying, the water content of betel nut is reduced to 22%, and the softness can still reach 80N, which is the softness level of 26% water content of betel nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com