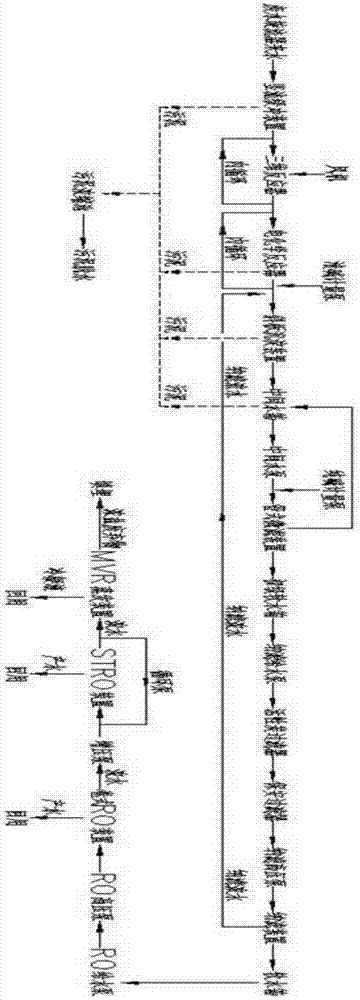

Desulfurization wastewater treatment process

A technology for desulfurization wastewater and treatment process, applied in the field of environmental protection, can solve the problems of scaling, the equipment does not have the meaning of promotion, and the pretreatment system process is incomplete, and achieves the effects of standardized management, remote real-time supervision, and increased processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The desulfurization wastewater passes through the vertical flow buffer device with reinforced concrete structure, and the desulfurization wastewater is preliminarily precipitated to reduce the sludge treatment load in the subsequent process section, and then undergoes primary electrochemical treatment through the three-dimensional reactor; the three-dimensional reactor is equipped with catalytic electrolytic fillers , The first-level electrochemical treatment of desulfurization wastewater can eliminate part of the acidic substances in the wastewater. In order to enhance the treatment effect, the equipment is equipped with an air stirring device. The residence time of the wastewater in the three-dimensional reactor is not less than 2 hours, and the air volume required by the air stirring device is designed according to the air-water ratio of 15:1. In order to promote full contact between the waste water and the internal packing of the three-dimensional reactor, the device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com