Bacillus amyloliquefaciens strain and microbial agent and preparation method of microbial agent

A technology of amyloliquefaciens and bacilli, which is applied in the field of microorganisms, can solve problems such as difficulty in achieving standardized control, difficult cost, and uneven tenderization effects, and achieve high food safety, simple preparation methods, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A strain of Bacillus amyloliquefaciens, which the inventor isolated from Guizhou traditional fermented soya bean and sweet wine koji. After the study of the morphological characteristics of the strain, it was used in beef products, showing the advantages of the strain as a special tenderizer for meat, and has great potential to be developed into a commercial food tenderizer. There were 22 strains of protease-producing bacteria, and one strain with higher enzyme activity was screened out, named Bacillus amyloliquefaciens D7, with an enzyme activity of 71.68 U / g.

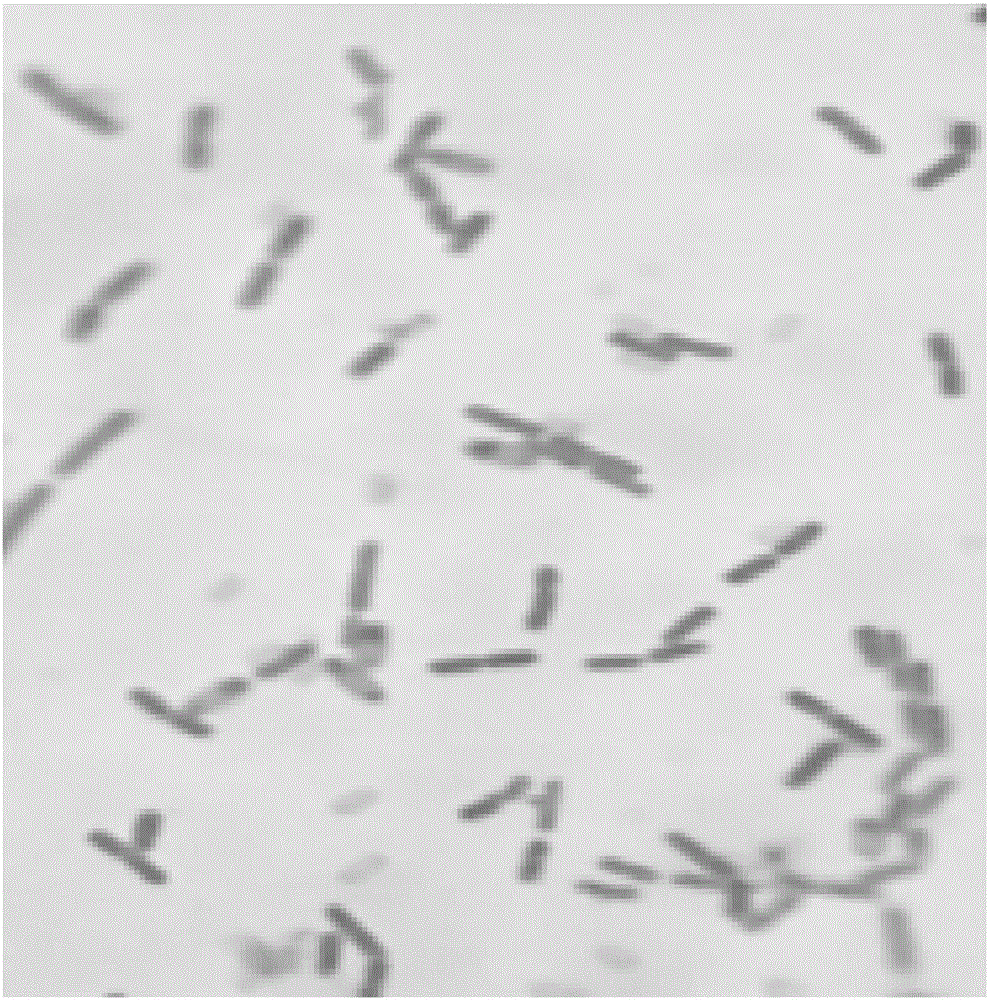

[0028] Bacillus amyloliquefaciens D7, on the isolation medium, the strain D7 is a white, smooth and moist colony, slightly raised, with folds in the middle of the colony, it is a spore-forming Gram-positive bacillus, figure 1 It is the Gram stain characteristic map under the electron microscope of the Bacillus amyloliquefaciens strain. Bacillus amyloliquefaciens D7 is film-like on the slope, with a white surfa...

Embodiment 2

[0032] A kind of Bacillus amyloliquefaciens bacterial agent, adopts following preparation method to prepare:

[0033] (1) Pick the Bacillus amyloliquefaciens strain from the slant culture medium in Example 1, inoculate it into the broth culture medium, and culture it on a shaker at 220 r / min for 12 hours at 37° C. to activate to obtain an activation solution.

[0034] (2) The activation solution was inoculated into the fermentation medium according to the inoculation amount of 3%, and cultured on a shaker at 220 r / min for 48 hours at 37° C. to obtain the Bacillus amyloliquefaciens bacterial agent.

[0035] Fermentation medium formula: glucose: 16.8g, yeast extract juice: 20g, NaCl: 2g, CaCl: 2g, dipotassium hydrogen phosphate: 5g, potassium dihydrogen phosphate: 1.25g, magnesium sulfate: 0.01g, iron sulfate: 0.001g , Distilled water: 1000mL, pH value: 7.66.

[0036] The Bacillus amyloliquefaciens inoculum of Example 2 is applied to beef tenderization. The specific steps are: ...

Embodiment 3

[0042] A preparation method of bacillus amyloliquefaciens bacterial agent, comprises the following steps:

[0043](1) Isolation of Bacillus amyloliquefaciens from Guizhou traditional tempeh and sweet wine koji. The strain is white, smooth and moist colony, slightly raised, with folds in the middle of the colony, which is a spore-forming Gram-positive bacillus, and a clearly visible transparent circle will be formed around it. It is filmy on slopes and has a white surface.

[0044] (2) The strain was purely cultured with an isolation medium, cultured in a biochemical medium box at 37°C for 24 hours, and then stored on a slant.

[0045] Separation medium formula: peptone: 10g, glucose: 1g, NaCl: 5g, CaCl: 0.1g, L-tyrosine: 0.1g, agar: 15g, casein: 5g, distilled water: 1000mL; pH value: 7.2~7.4 .

[0046] (3) Pick the strain of Bacillus amyloliquefaciens from the slant culture medium, inoculate it into the broth medium, culture it on a shaker at 220 r / min at 37°C for 12 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com