Holder for Beverage Containers

a beverage container and holder technology, applied in the field of beverage containers, can solve the problems of more difficult for foreign objects to enter the beverage container and more difficult for beverages to spill out of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

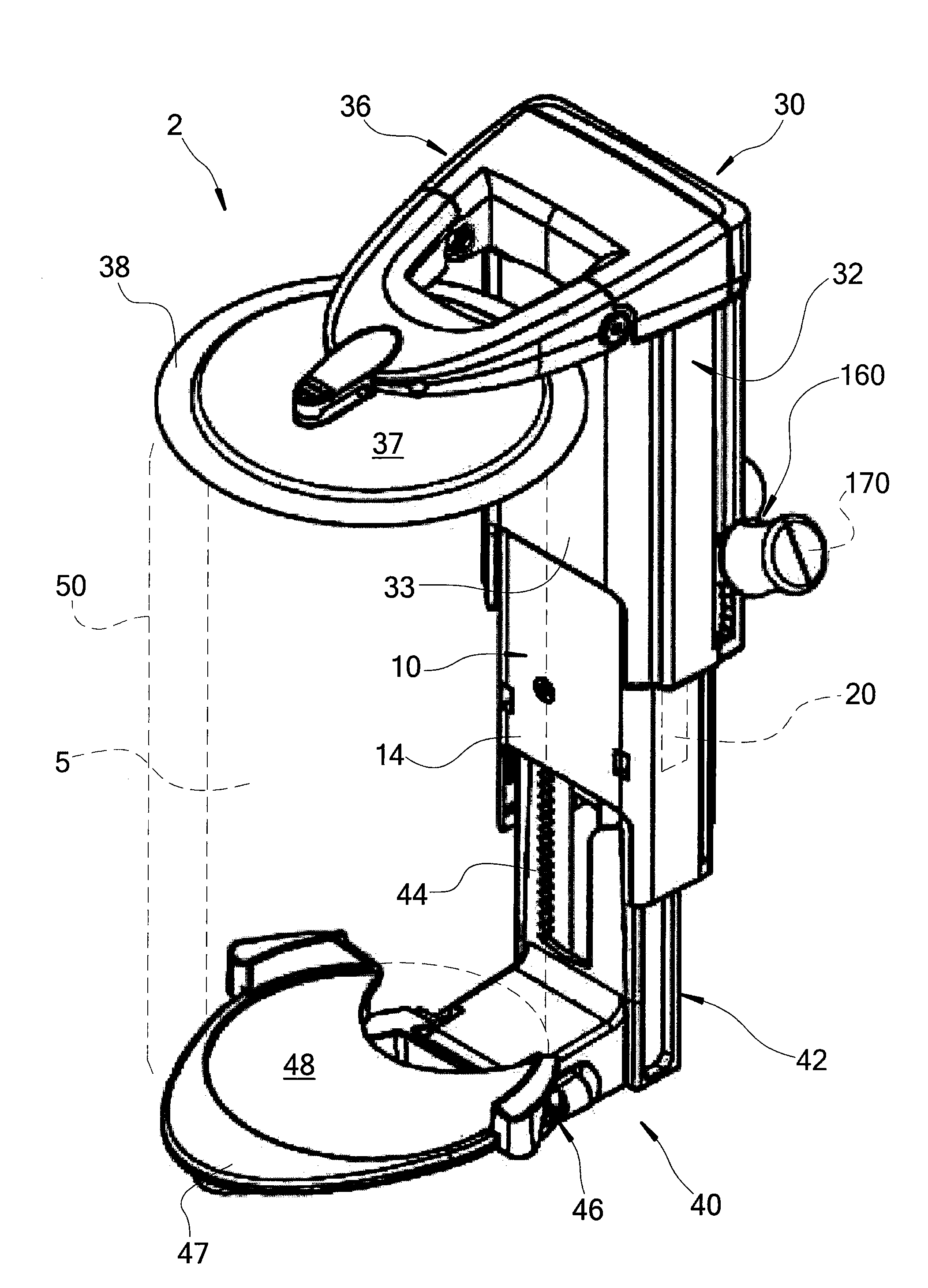

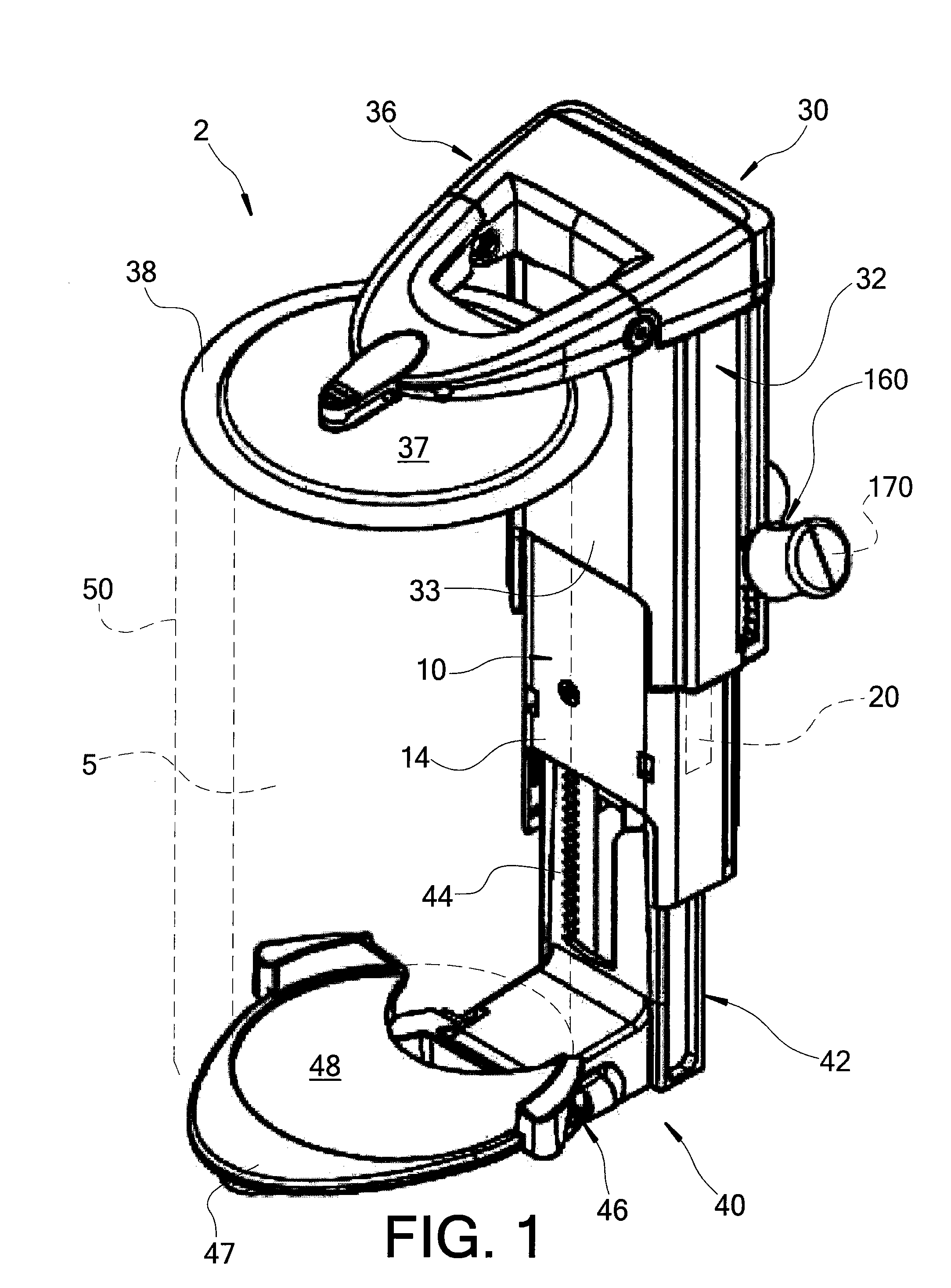

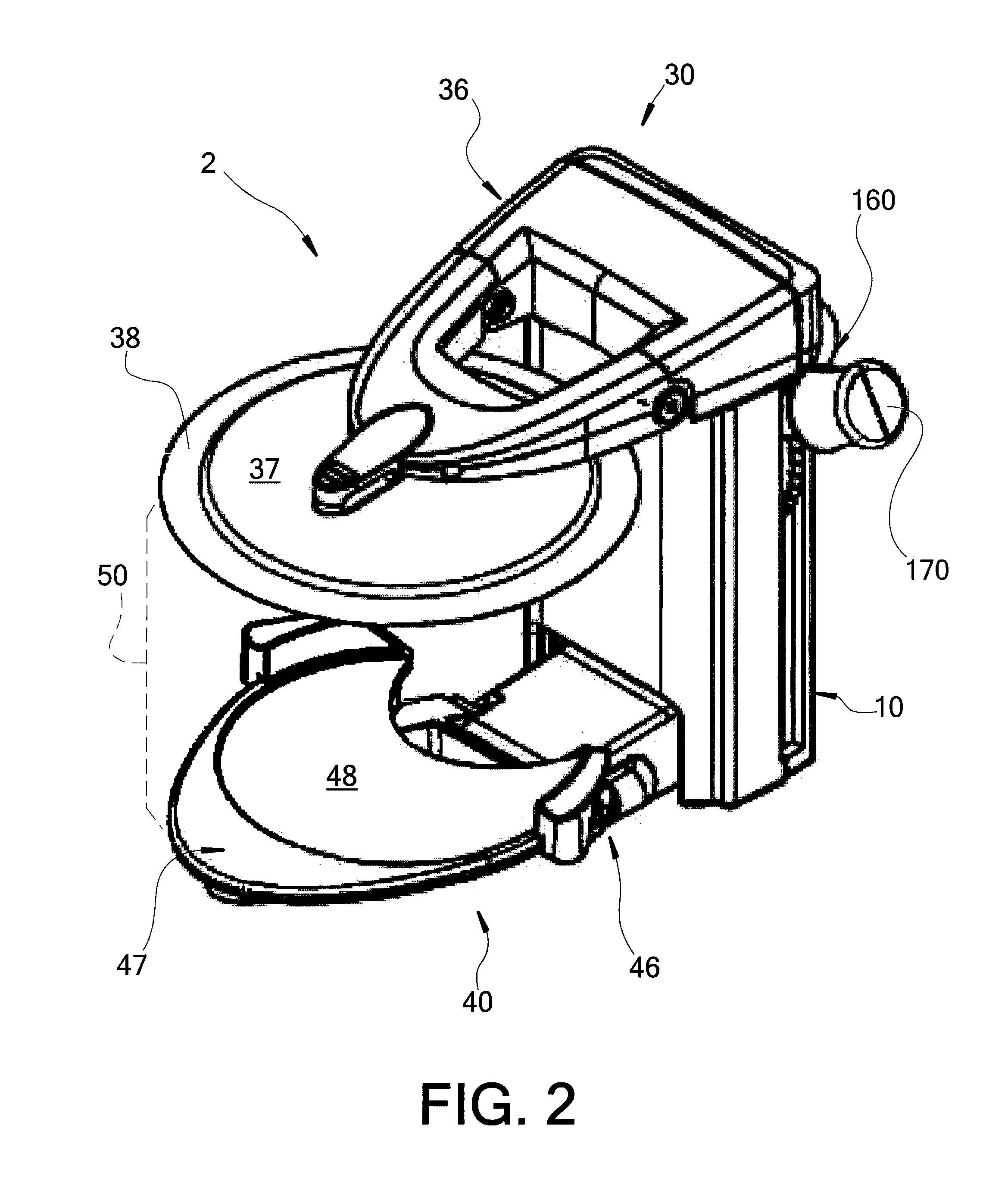

[0027]The present invention provides beverage container holders such as holders 2 that are adapted to hold a beverage container 5 in place, while simultaneously sealing or covering the beverage container 5, for example, with its holding structure(s). Holder 2 includes a base 10, in which an actuator 20 is housed, and upper and lower clamp assemblies 30 and 40 that are movably attached to the base 10. Upper and lower clamp assemblies 30 and 40 define an opening 50 therebetween and each can slidingly advance and regress with respect to its position relative the base 10. Movements of the upper and lower clamp assemblies 30, 40 performed in synchrony with each other, while occurring in opposing directions, allowing manipulation of just one of the upper and lower clamp assemblies 30, 40 to effectuate movement of them both, facilitating movement of the holder 2 between a fully retracted, default position (FIG. 2), toward a fully extended or open position (FIG. 1). This may be achieved by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com