Cerium oxide slurry, cerium oxide polishing slurry and method for polishing substrate using the same

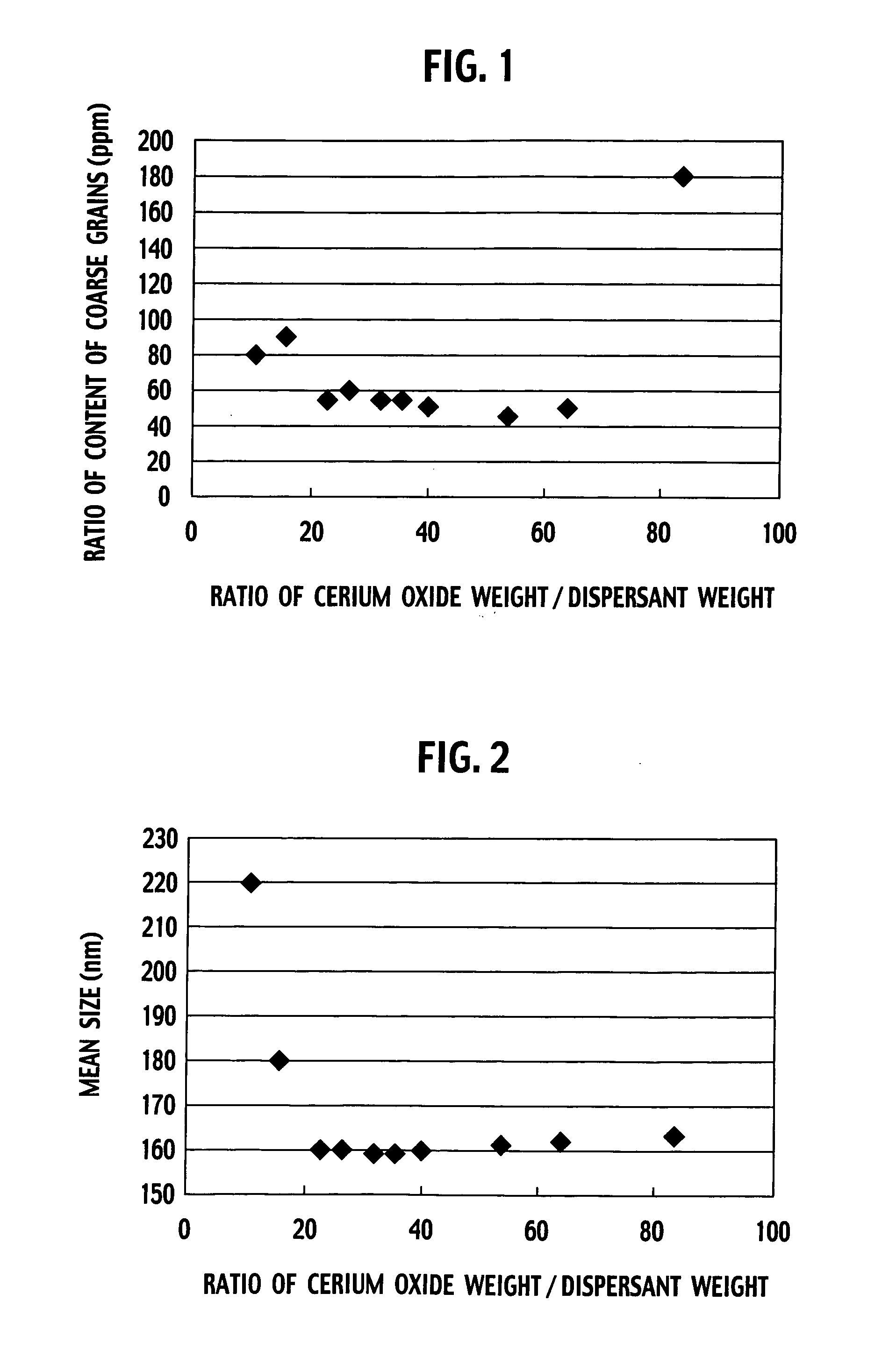

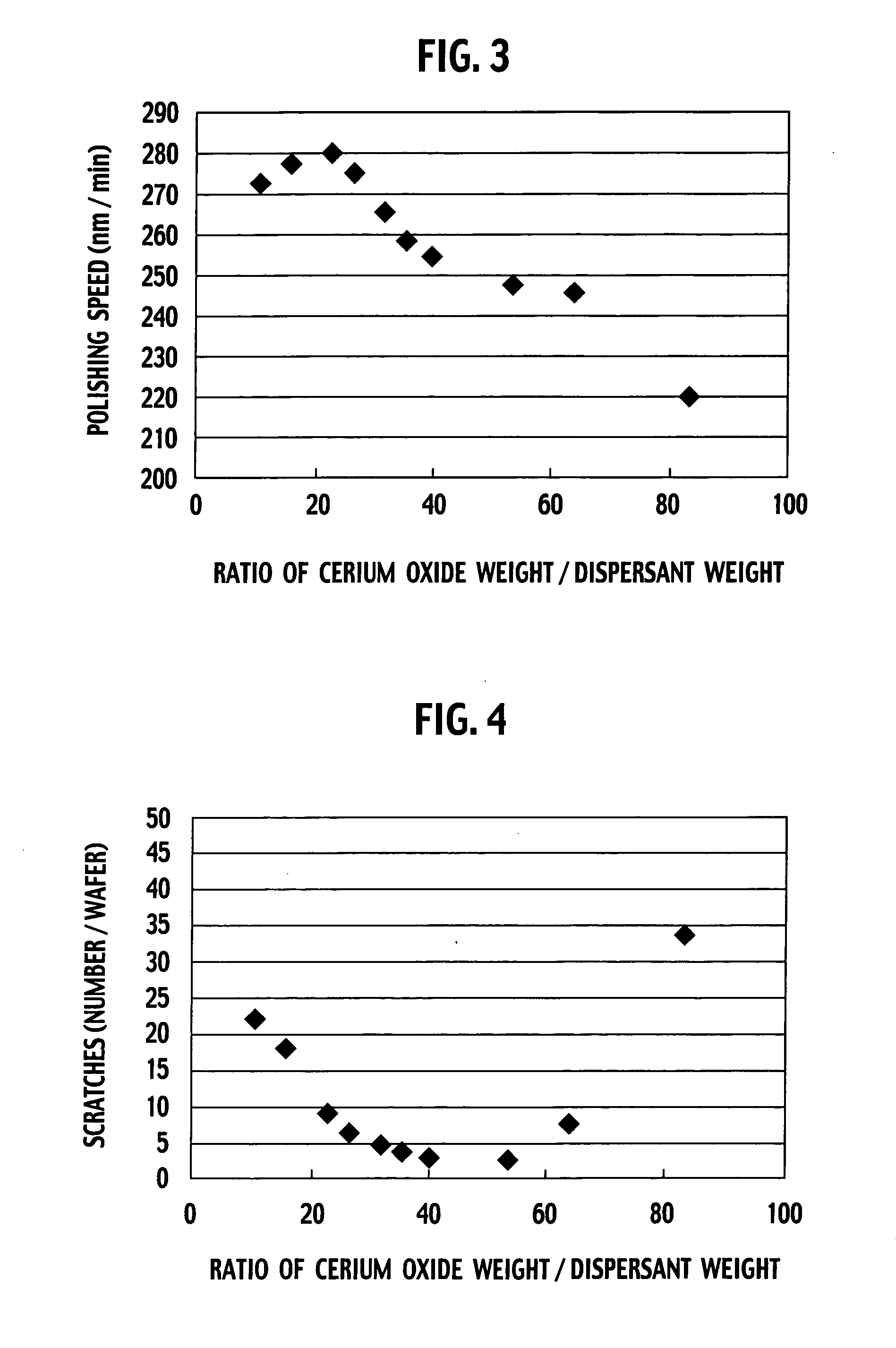

a cerium oxide and slurry technology, applied in the direction of lapping machines, manufacturing tools, other chemical processes, etc., can solve the problems of small polishing speed ratio low polishing speed of colloid silica polishing slurry, and far from practical property of shallow trench isolation, etc., to reduce the content ratio of coarse grains, reduce scratches and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 7

[0083] (Preparation of cerium oxide ground powder)

[0084] Forty kilo-grams of cerium carbonate hydrate was put in an aluminum container, and calcined in air for 2 hours at 830° C., and 20 kg of yellowish white powder was obtained. This powder was determined in phase by X-ray diffraction method, and was identified to be cerium oxide. The calcined powder particle size was 20 to 100 μm.

[0085] Twenty kilograms of the cerium oxide particle powder was ground in dry process by using a jet mill. The specific surface area of polycrystal was measured by BET method, and 9.4 m2 / g was obtained.

[0086] (Preparation of cerium oxide slurry)

[0087] The ground cerium oxide powder, 10.0 kg, was mixed with 116.65 kg of deionized water, and 228 g of commercial aqueous solution of ammonium salt polyacrylate (weight-average molecular weight 8000, 40% by weight) was added as dispersant, and the mixture was stirred for 10 minutes. By ultrasonic irradiation in piping for sending into other container, cerium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com