Vacuum auxiliary molding technique produced by large-sized sandwich composite material

A composite material, vacuum-assisted technology, applied in the field of composite material molding, to achieve the effect of avoiding sag, avoiding dry spots, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

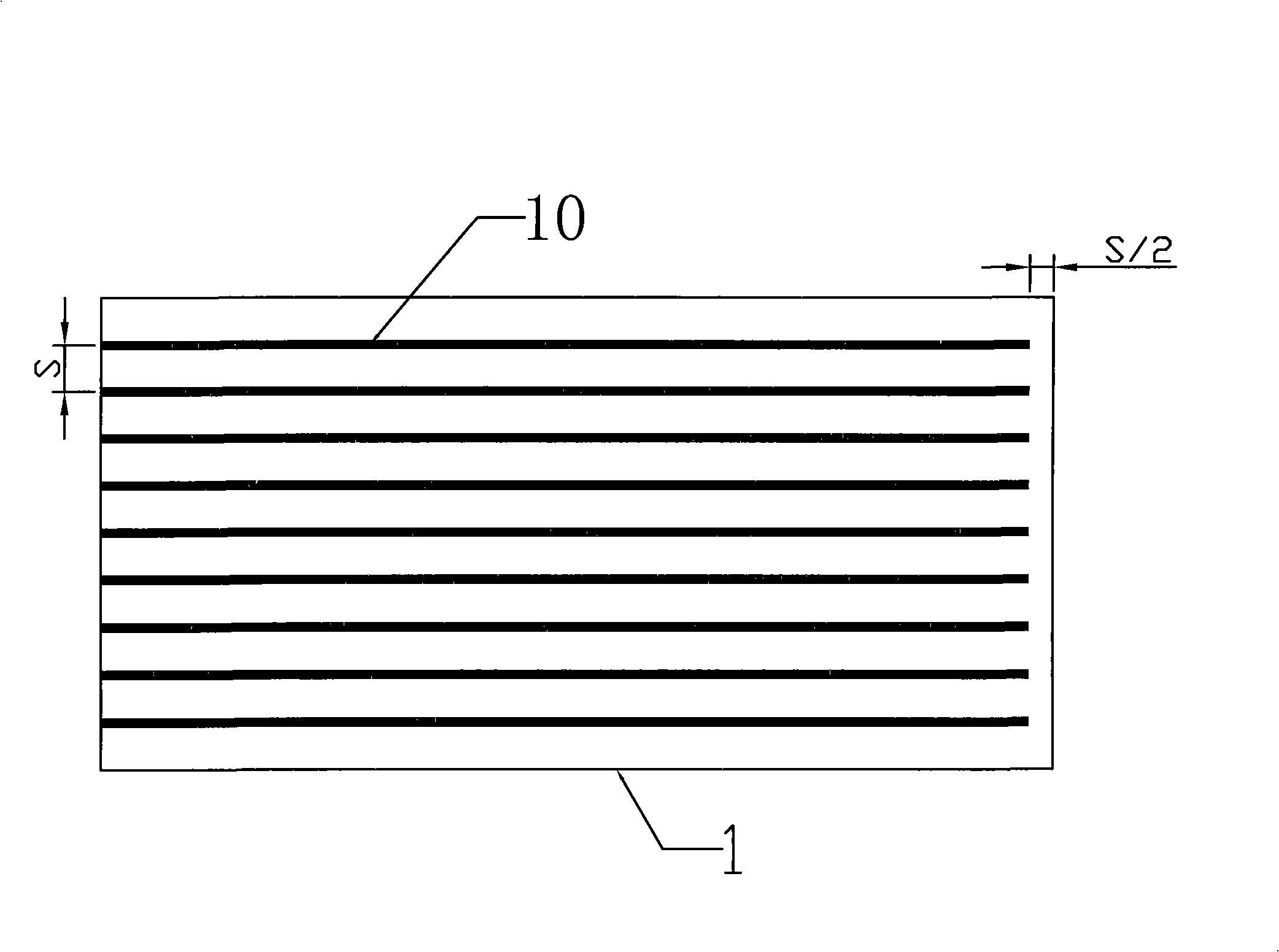

[0016] The size of the composite sandwich structure is 600mm×1000mm, the foam core material is polyurethane foam, and the thickness is 15mm; the surface density of the upper and lower panels is 220g / m 2 The S glass fiber satin weave cloth has a thickness of 2 mm after molding; the vacuum-assisted forming scheme of the present invention is used to implement the overall molding of the sandwich structure of composite materials.

[0017] 1. Open a set of grooves along the length direction of the polyurethane foam core material. The width of the grooves is 4mm, the depth is 1mm, the distance between the grooves is 60mm, and the distance between the foam core material and the grooves is 30mm.

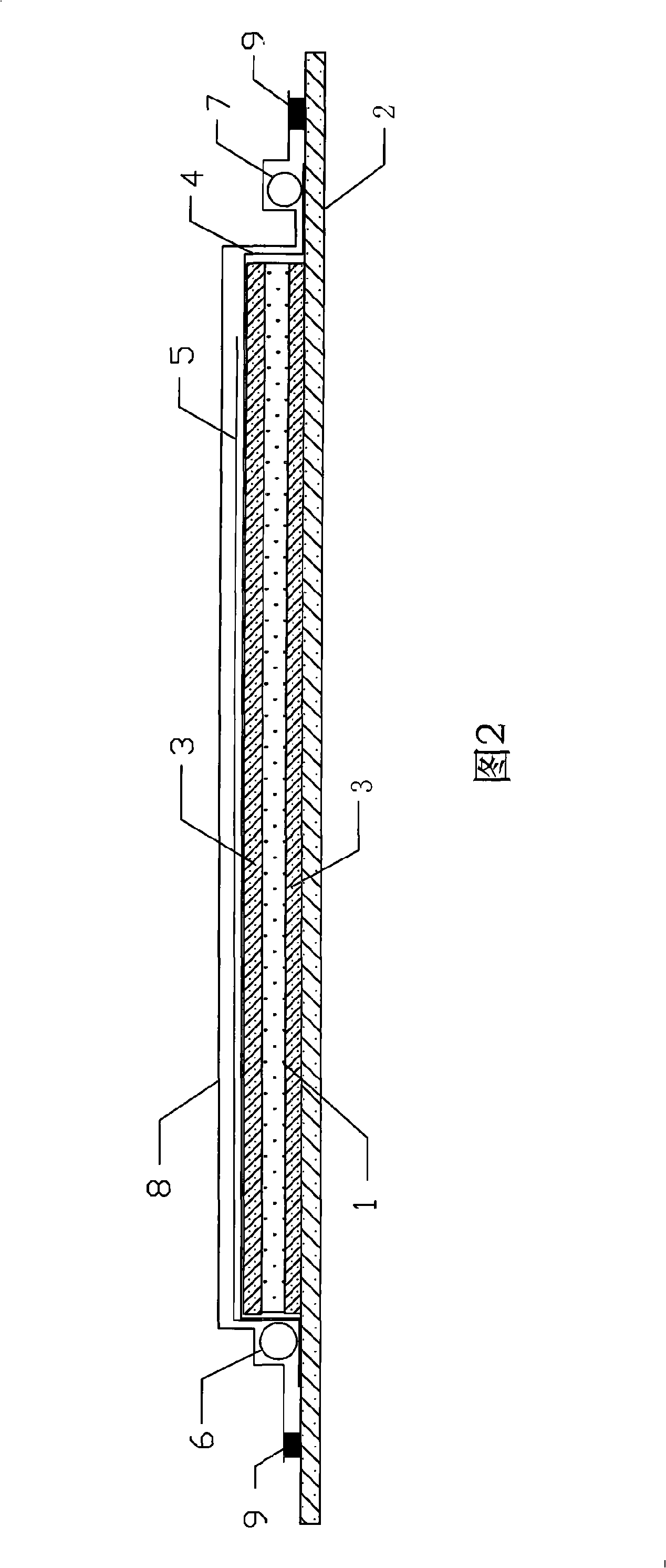

[0018] 2. Spread 10 layers of S glass fiber satin cloth cut according to size on the mold that has been cleaned and coated with release agent; place the processed polyurethane foam core material on the glass fiber fabric, and place the groove surface In contact with the fabric; then spread 10...

Embodiment 2

[0026] The size of a composite sandwich structure is 1600mm×2000mm, the foam core material is polyvinyl chloride foam, the thickness is 15mm, and the surface density of the upper and lower panels is 220g / m 2 The S glass fiber satin cloth, the thickness of the panel after forming is 1mm, and the vacuum-assisted forming scheme of this patent is used to implement the overall forming of the composite sandwich structure.

[0027] 1. Open a set of grooves along the length direction of the polyvinyl chloride foam core material. The width of the groove is 5mm, the depth is 4mm, the distance between the grooves is 100mm, and the distance between the foam core material and the groove is 50mm.

[0028] 2. Spread 5 layers of cut S glass fiber satin cloth on the mold that has been cleaned and coated with release agent; place the grooved PVC foam core material on the glass fiber fabric, and place the groove The surface of the groove is in contact with the fabric; then lay 5 layers of S-fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com