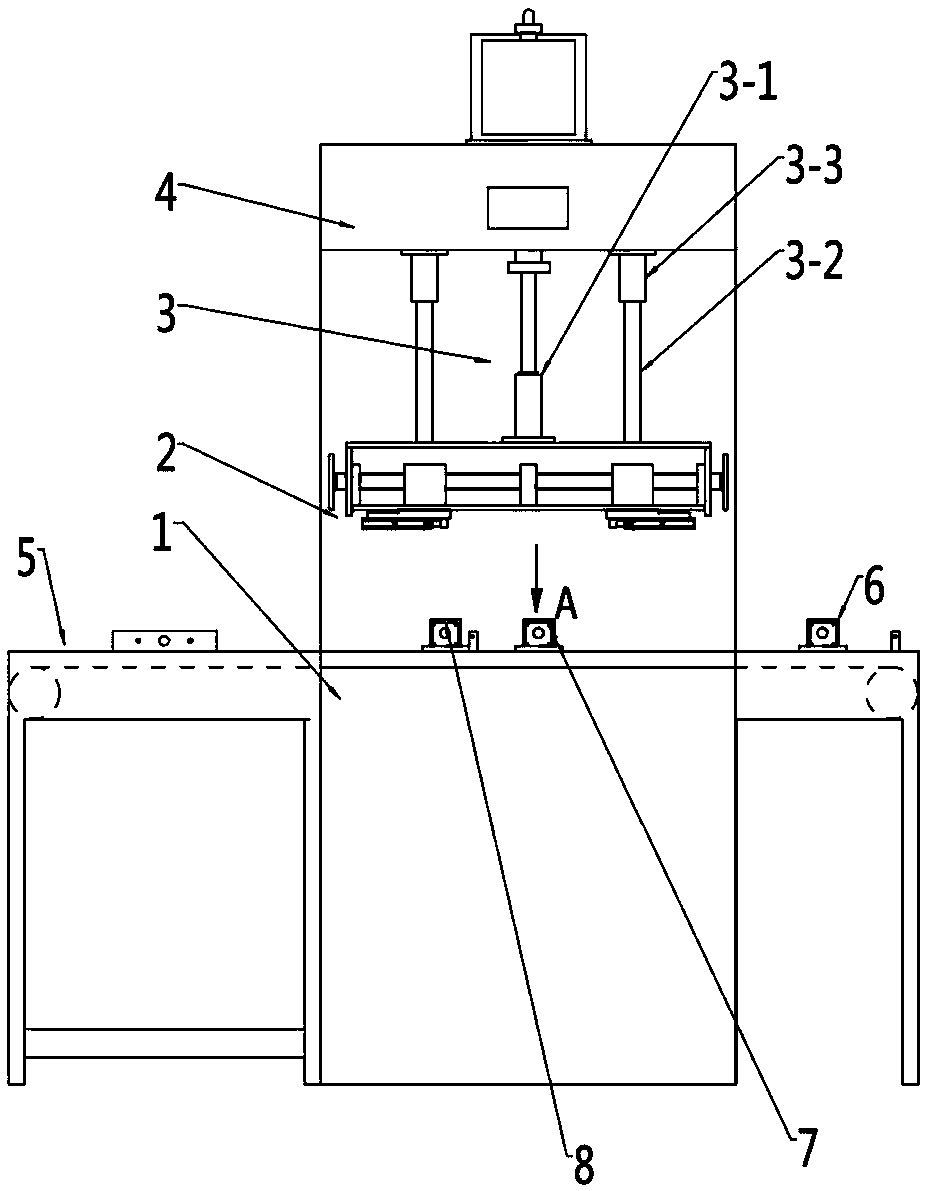

Storage battery airtightness detection and inflation method and equipment

A technology for air tightness detection and inflatable equipment, which is applied in liquid tightness measurement using liquid/vacuum degree, battery machine assembly, climate sustainability, etc. Insufficient and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

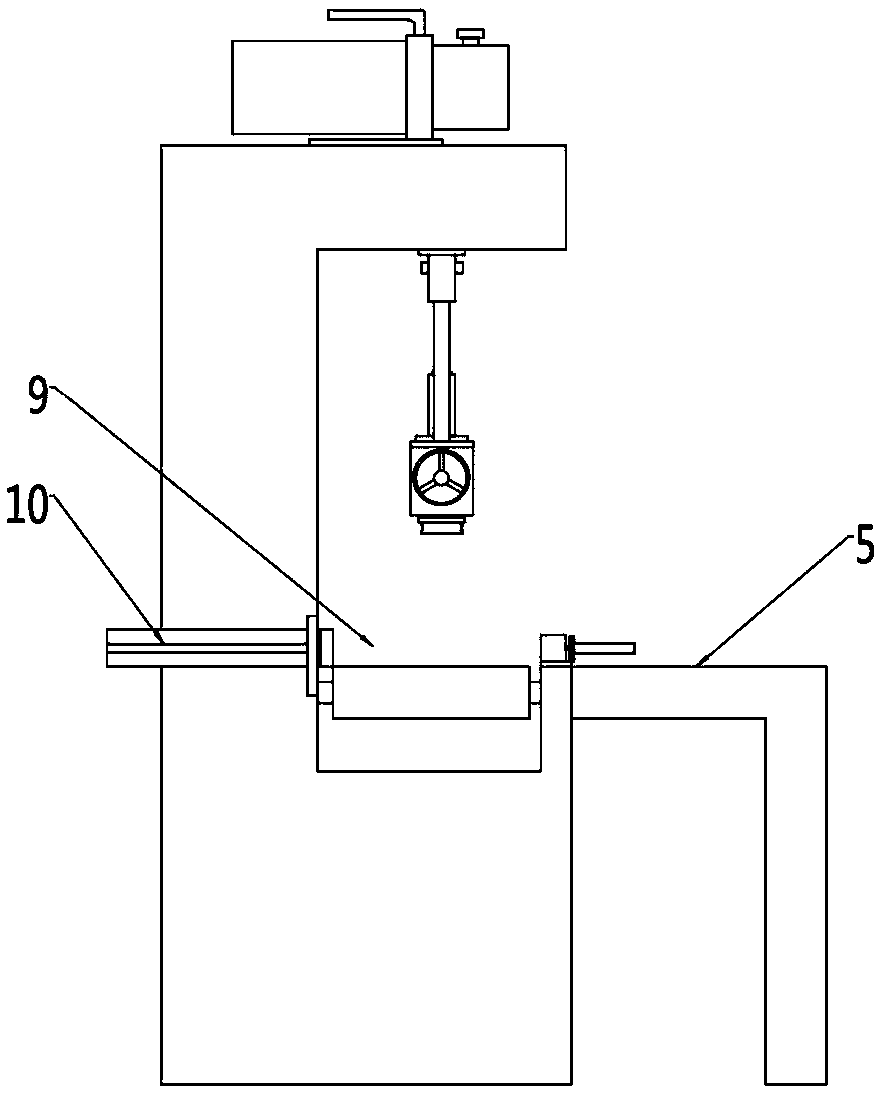

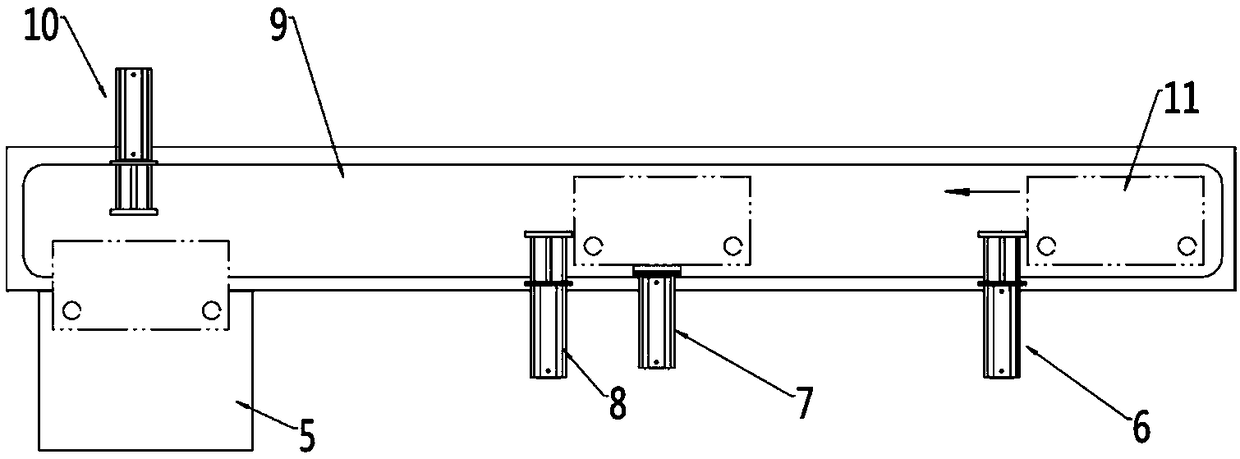

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The model of the battery to be tested is 6QW-60, and the battery to be tested is transported to the detection position by the battery delivery track of the equipment described in the present invention, and the air cylinder on both sides of the battery is closed by clamping the cylinder, the vacuum air pipe is opened, and the protective gas The trachea is closed, and the vacuum pump pumps vacuum into the battery; the vacuuming time is 15 seconds, and the internal pressure of the battery is 3KPa, so it is judged that the sealing of the battery is unqualified.

Embodiment 2

[0035] Embodiment 2: The model of the battery to be tested is 6QW-80, and the battery to be tested is transported to the detection position by the battery delivery track of the equipment described in the present invention, and the air cylinder on both sides of the battery is closed by clamping the cylinder, the vacuum air pipe is opened, and the protective gas The trachea is closed, and the vacuum pump pumps vacuum into the battery; the vacuuming time is 10 seconds, the internal pressure of the battery is -26KPa, and the internal pressure of the battery is -25.9Kpa after holding the pressure for 8 seconds. The gas gas pipe is connected and opened, and the protective gas carbon dioxide is charged into the battery, and the inflation time is 5-8s, and the internal pressure of the battery is charged to 8Kpa.

Embodiment 3

[0036] Embodiment 3: The model of the battery to be tested is 6QW-100, and the battery to be tested is transported to the detection position by the battery delivery track of the equipment described in the present invention. The trachea is closed, and the vacuum pump pumps vacuum into the battery; the vacuuming time is 9 seconds, the internal pressure of the battery is -23KPa, and the internal pressure of the battery is -22.7Kpa after holding the pressure for 9 seconds. The gas gas pipe is connected and opened, and the protective gas carbon dioxide is charged into the battery, and the inflation time is 5-8s, and the internal pressure of the battery is charged to 10Kpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com