Cooler in driving gearbox, and cooling structure and method of driving gearbox

A technology of cooling structure and cooler, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc. It can solve the problems of unreliable sealing structure, unsatisfactory heat dissipation effect, short cooling water flow path, etc., and achieve reliable Effective cooling and heat dissipation, avoiding cooling water leakage, and long cooling channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

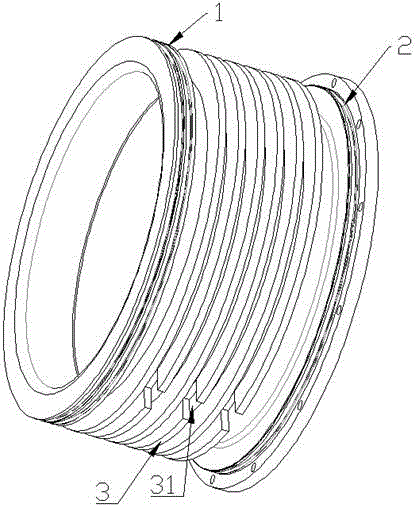

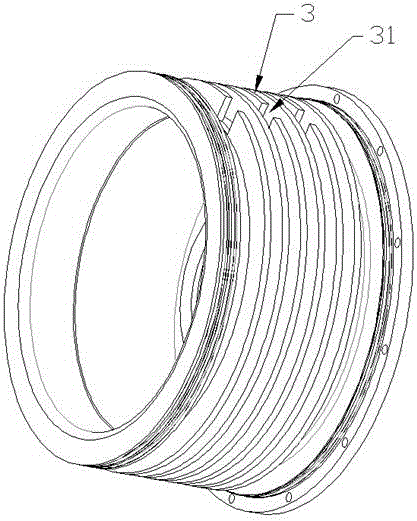

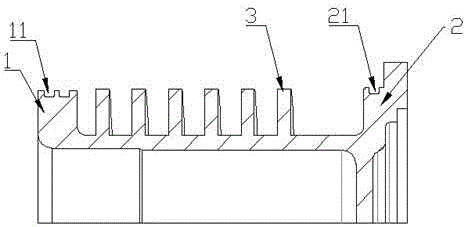

[0028] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0029] Drive the cooler in the gear box. The cooler has a cylindrical structure with an open top. The top and bottom of the cooler are respectively provided with an annular sealing plate 1 and a sealing plate 2. The cooler is also provided with an annular The interlayer 3, the interlayer 3 is arranged between the sealing plate one 1 and the sealing plate two 2, the interlayer 3 is axially separated from the sealing plate one 1 and the sealing plate two 2, and the interlayer 3 is provided with A water gap 31, the water gap 31 of the adjacent interlayer 3 is staggered by a certain angle along the circumferential direction of the interlayer 3.

[0030] Such as figure 1 As shown in the cooler, it is installed in the driving gearbox, sealing plate 1 and sealing plate 2 are used to seal the cooler in the driving gearbox to ensure that the cooling water will not flow out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com