Collecting electric field-ultrasonic wave field-centrifugal field coupled anti-scaling temperature control electric coalescence dehydrator

An ultrasonic field, coalescence dehydration technology, applied in the direction of electric/magnetic dehydration/demulsification, mechanical dehydration/demulsification, petroleum industry, etc., can solve the adverse effects of the normal operation of the electric dehydrator Large land area, high construction and operating costs, etc., to avoid hot water scaling, increase the probability of collision coalescence, and prolong the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

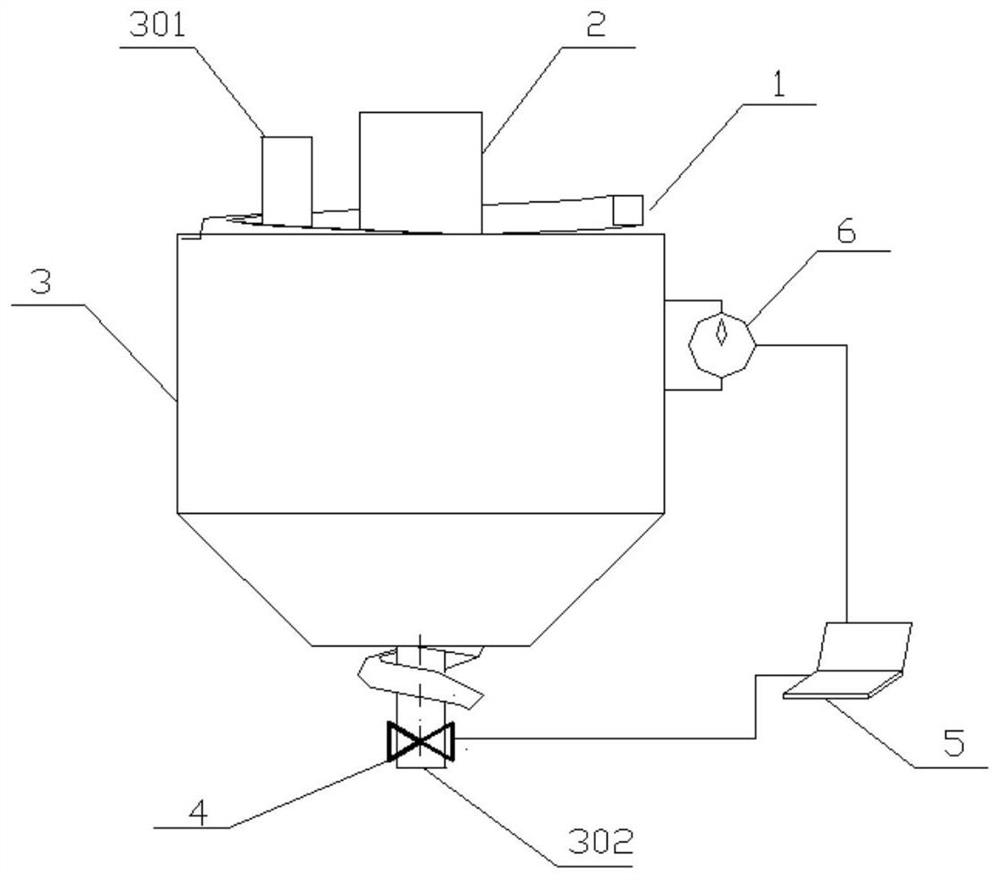

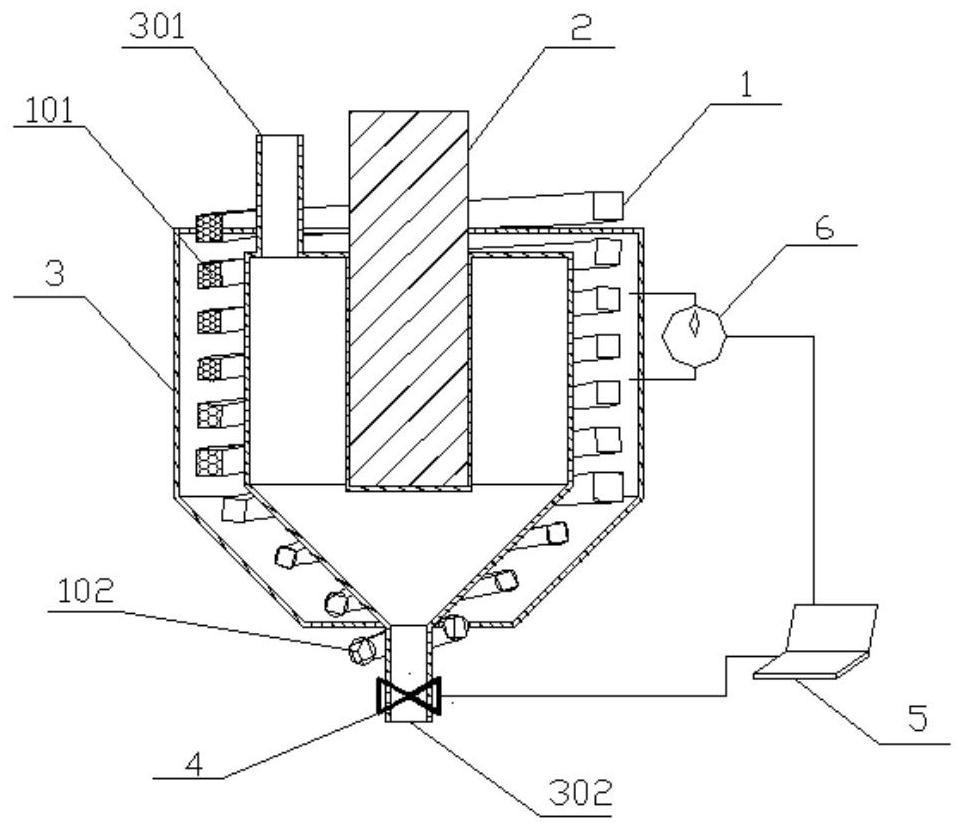

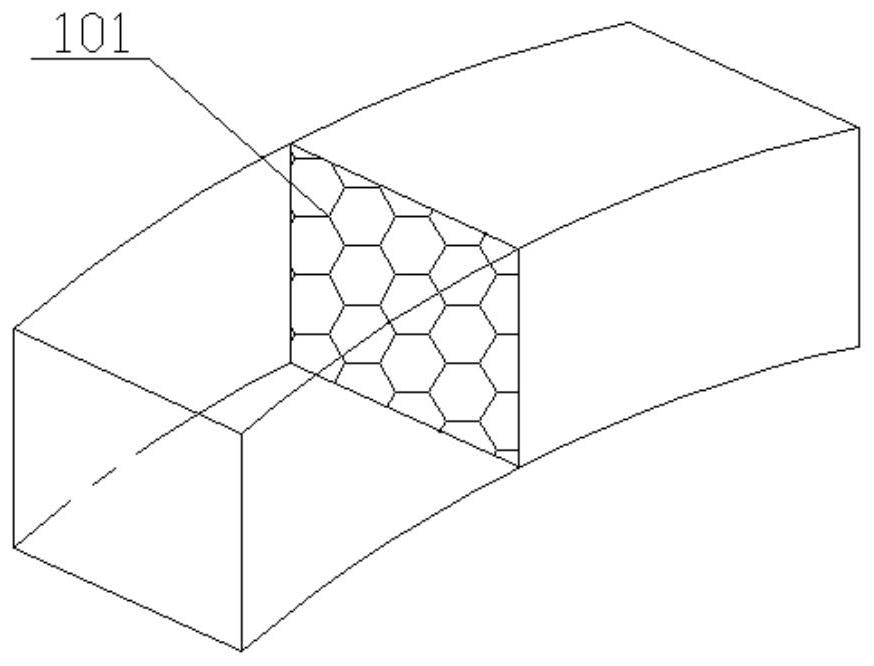

[0030] Such as figure 1 , 2 The shown electric field-ultrasonic field-centrifugal field coupled anti-scaling temperature-controlled electric coalescence dehydrator includes a thermal insulation tank 3, and the thermal insulation tank 3 has two inner and outer shells coaxially arranged, the inner shell and the outer shell The layer shell is cylindrical, and the bottom of the cylinder is conical, the bottom of the outer shell is connected with the bottom of the inner shell, and the inner shell and the outer shell are installed Filled with heat transfer oil and closed, the heat transfer oil can enha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com