CO2-N2 enhanced crude electrostatic desalting method

A CO2-N2, electric desalination technology, applied in the direction of electric/magnetic dehydration/emulsification, petroleum industry, hydrocarbon oil treatment, etc., can solve the problem of high emulsification degree and water content of crude oil, increased chemical dosage, heavy crude oil The degree of inferiority is serious and other problems, to achieve the effect of reducing the salt content and cut oil content of crude oil, reducing the treatment cost, and reducing the salt content and cut oil content of crude oil after stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

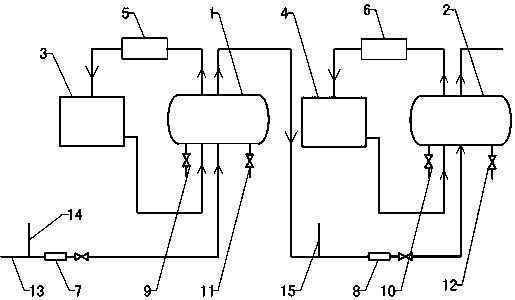

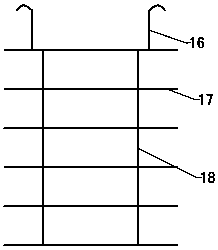

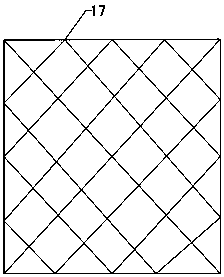

[0032] Figure 1~5 It is the best embodiment of the present invention. Figure 1~5 The present invention will be further explained.

[0033] Reference attached Figure 1~4 : A kind of CO 2 -N 2 The method of strengthening the electrical desalination of crude oil includes the following steps:

[0034] 1) Statically mix crude oil and water;

[0035] 2). After fully mixing, it is injected into the first-level electrical desalination device for first-level electrical desalination, and CO is continuously injected into the first-level electrical desalination device during the desalination process 2 Foam, water droplets are fully coalesced and separated, and the remaining CO is recovered at the same time 2 gas;

[0036] 3) The crude oil after the primary reaction is injected into the secondary electric desalination device, and water is injected into the crude oil in the secondary electric desalination device again, so that the crude oil and the re-injected water undergo a secondary static mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com