Underground while-drilling bidirectional eccentric nipple reaming drilling tool

A drilling tool and eccentric technology, which are applied in drilling equipment, drilling equipment and methods, and earthwork drilling, etc., can solve problems such as difficulty in running casing in soft formations, cuttings bed sticking, borehole necking and stuck drilling, etc. Achieve the effect of strong integrity, eliminating damage and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

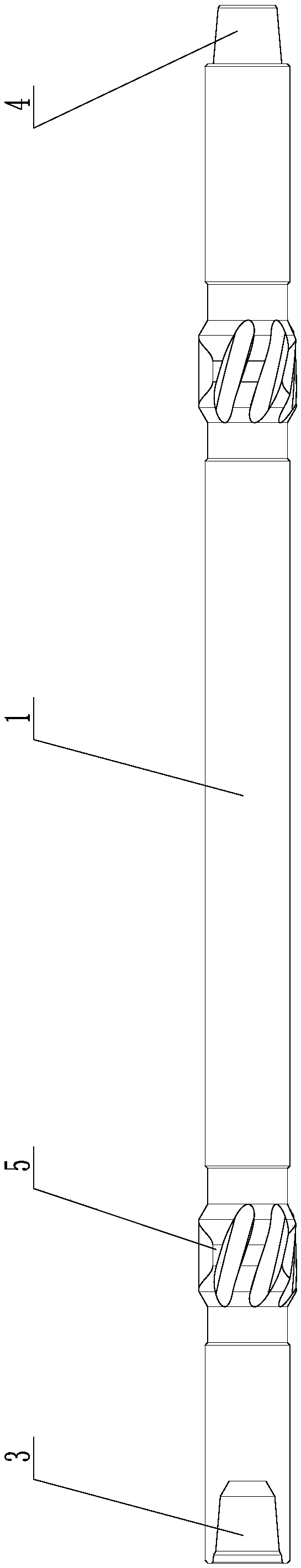

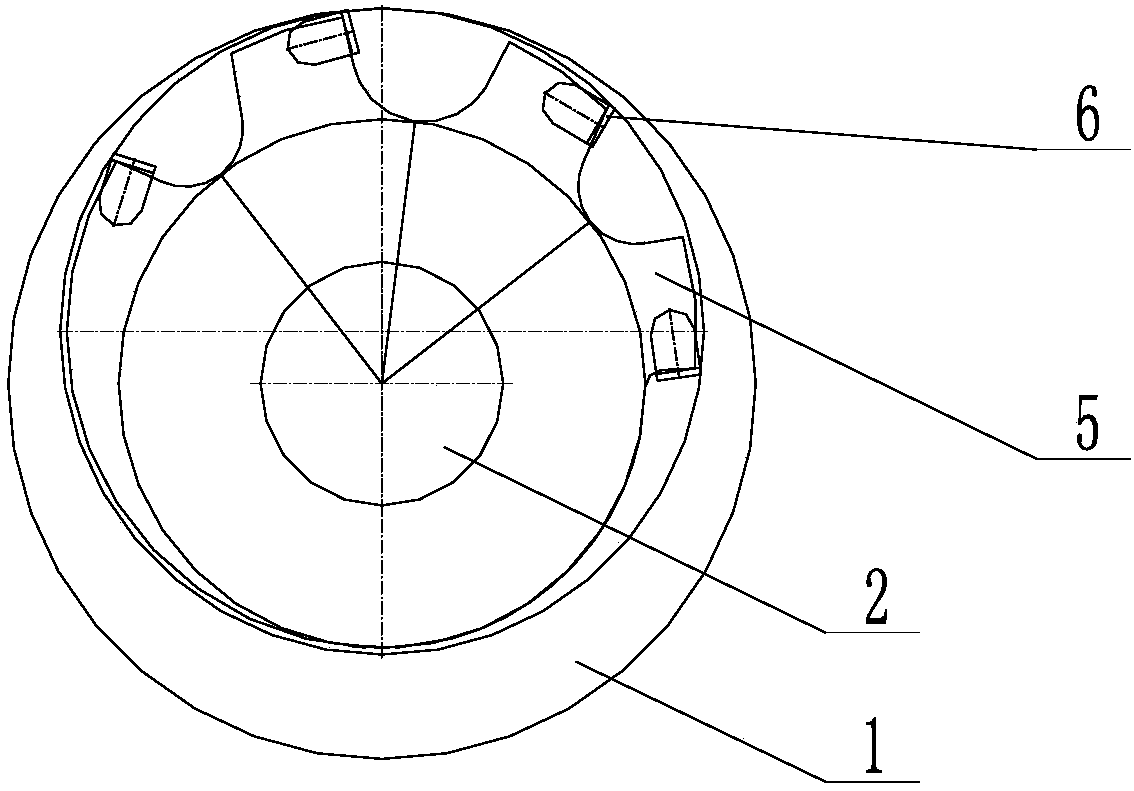

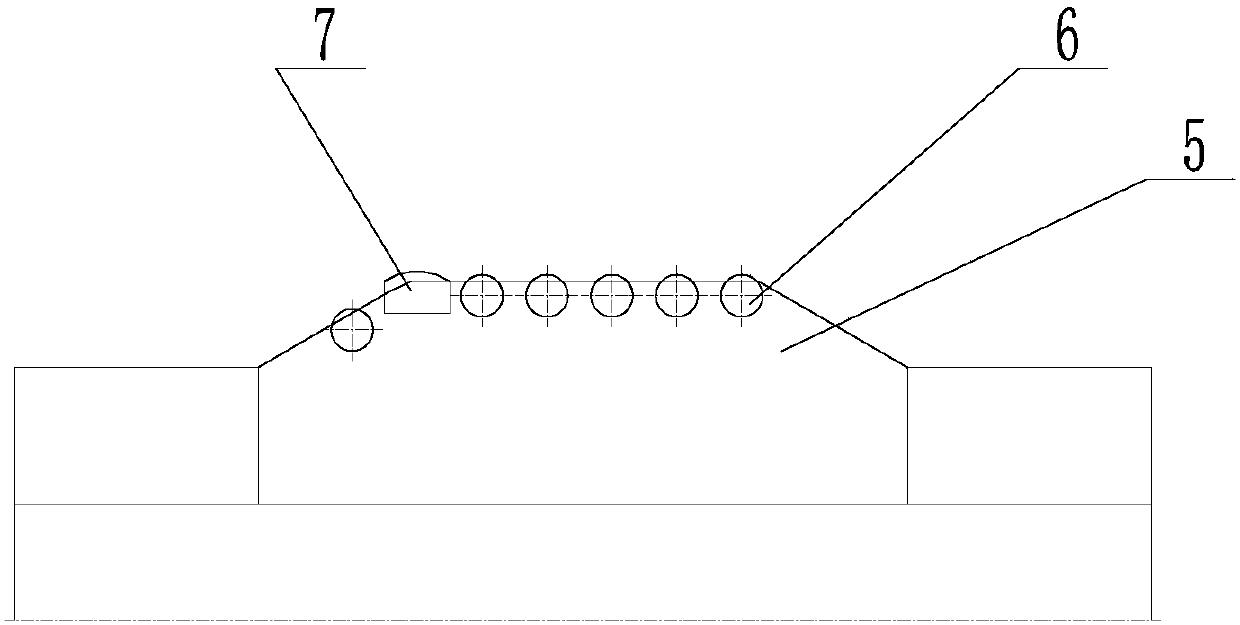

[0026] as attached Figure 1-3 As shown, a downhole drilling tool for bidirectional eccentric sub-joint reaming while drilling includes a body 1, a water hole 2 is arranged in the center of the body 1, and a box 3 connected to the upper drill string is arranged at one end of the body 1. The other end of the body 1 is provided with a male buckle 4 connected to the lower drill string, and two groups of eccentric reamers are provided outside the body 1, and each group of reamers includes four blades 5, each of which is PDC cutting teeth 6 are brazed on the blade 5 described above.

[0027] The blade 5 is also brazed with a wear-resistant protective column 7 .

[0028] The wear-resistant protection column 7 is 0.5-1mm higher than the PDC cutter 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com