Novel framework die-casting die for steering wheel

A die-casting mold and steering wheel technology, which is applied in the field of new steering wheel skeleton die-casting molds, can solve the problems of increasing scrap rate, low molding rate, and increasing production and manufacturing costs, so as to reduce the generation of surface cracks, improve molding efficiency, and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

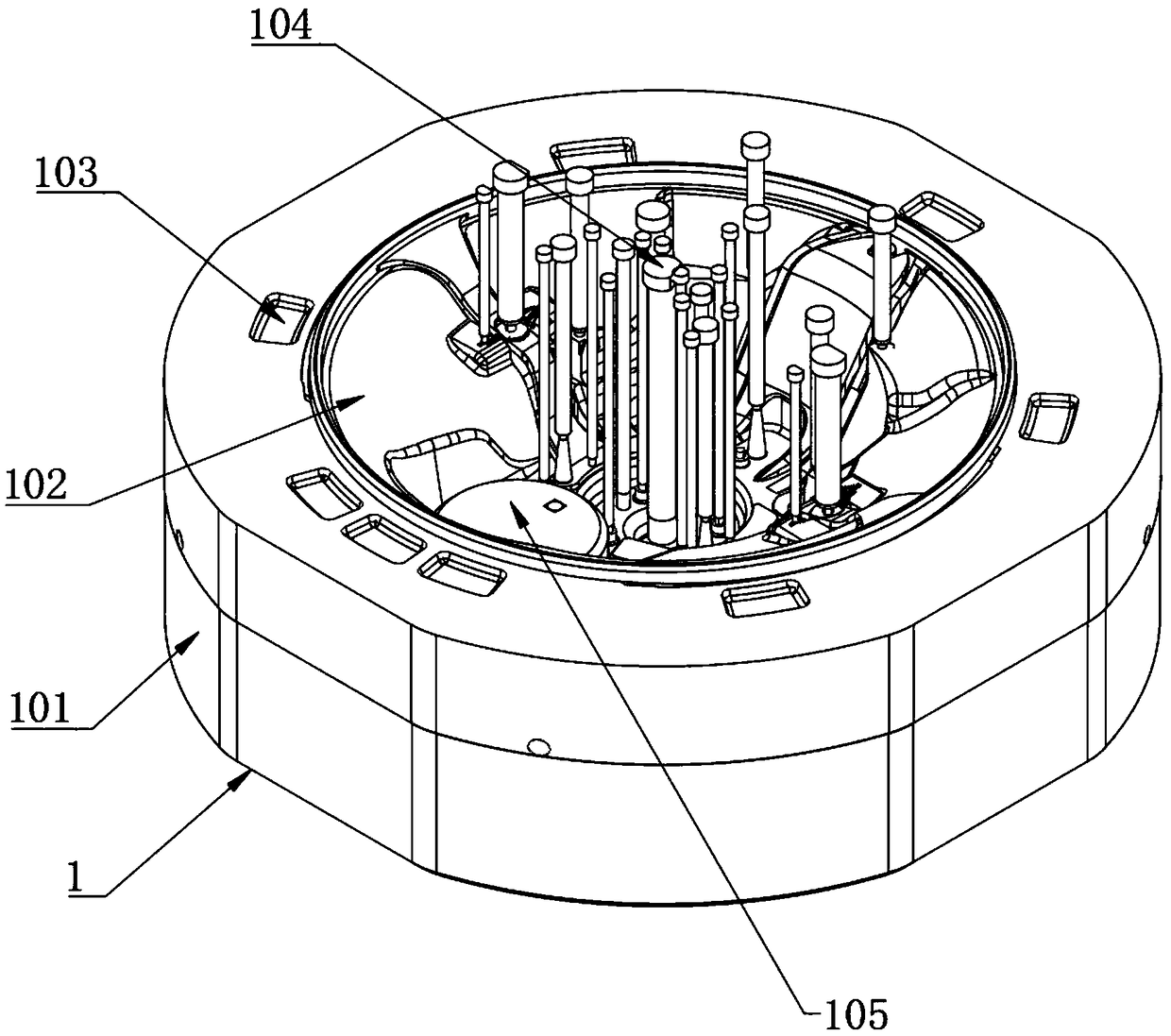

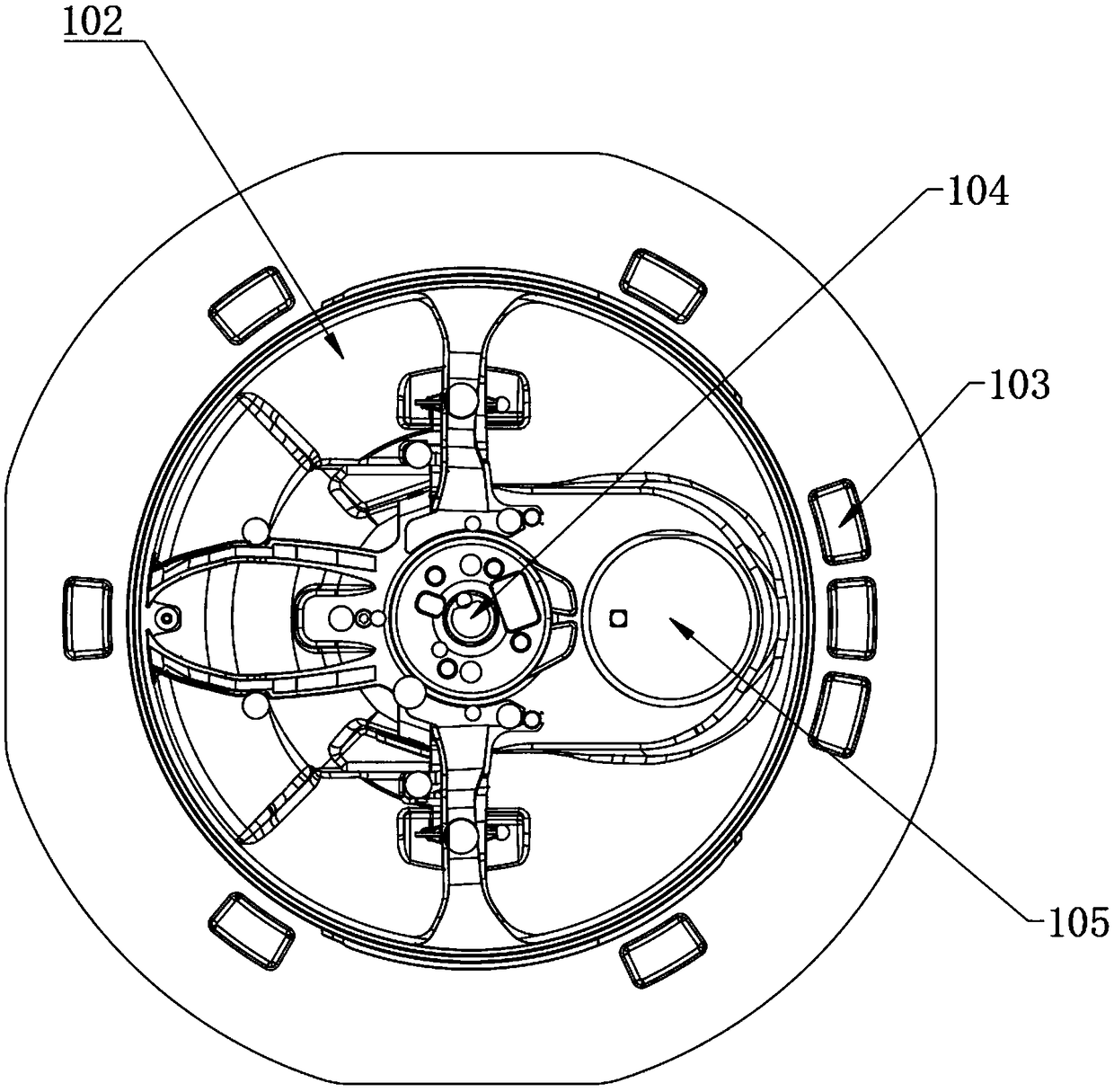

[0026] as attached figure 1 to attach Figure 7 Shown:

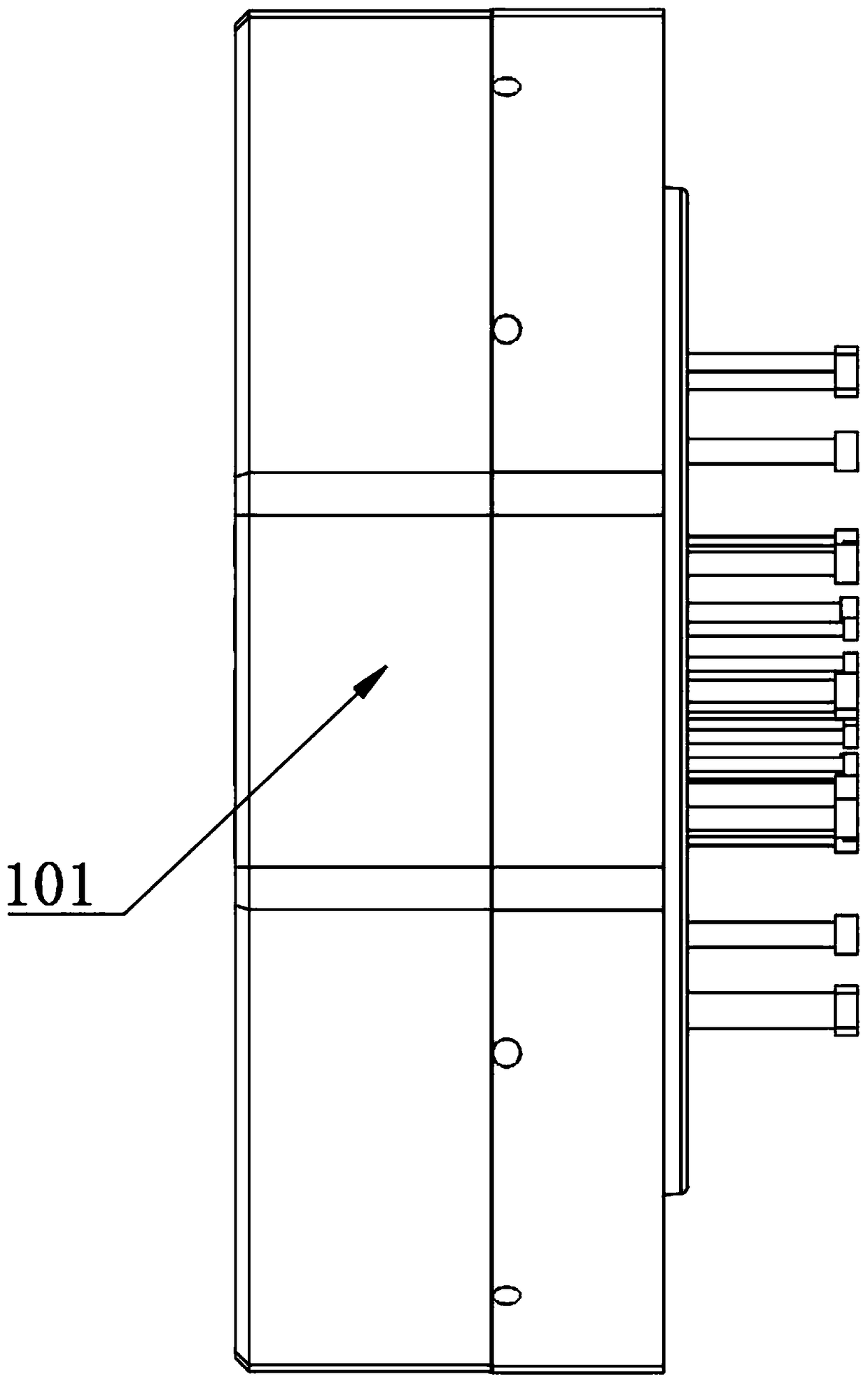

[0027] The present invention provides a novel steering wheel skeleton die-casting mold, which includes: a fixed mold 1, a fixed mold frame 101, a fixed mold core 102, a positioning hole 103, a round rod 104, a rear core-pulling structure 105, a movable mold 2, and a movable mold frame 201 , a positioning block 202, a sprue sleeve 203, a through hole 204, a movable mold core 205 and a front core-pulling structure 206; the top surface of the fixed mold frame 101 has a positioning hole 103; the movable mold frame 201 has a through hole 204 ; The fixed mold frame 101 is provided with a round rod 104, and the round rod 104 is connected with the through hole 204; the movable mold core 205 is installed in the lower end surface of the movable mold frame 201; the upper end surface of the fixed mold frame 101 Fixed mold core 102 is installed.

[0028] Wherein, both the fixed mold 1 and the movable mold 2 are equipped with cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com