Adhesive sealing method and packaging device for hollow fiber curtain type membrane element

A fiber membrane and curtain membrane technology, applied in the field of hollow fiber curtain membrane element sealant and its packaging device, can solve problems such as low production efficiency and complicated sealant process, and achieve improved product quality, simple pouring process, and sealing The effect of unimpeded glue flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

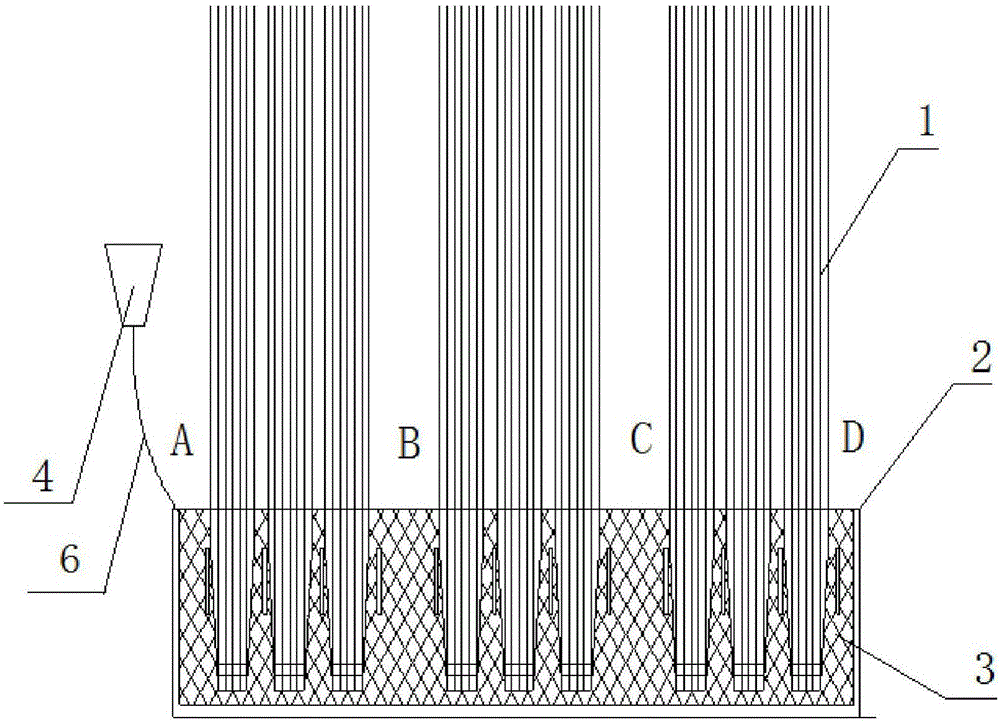

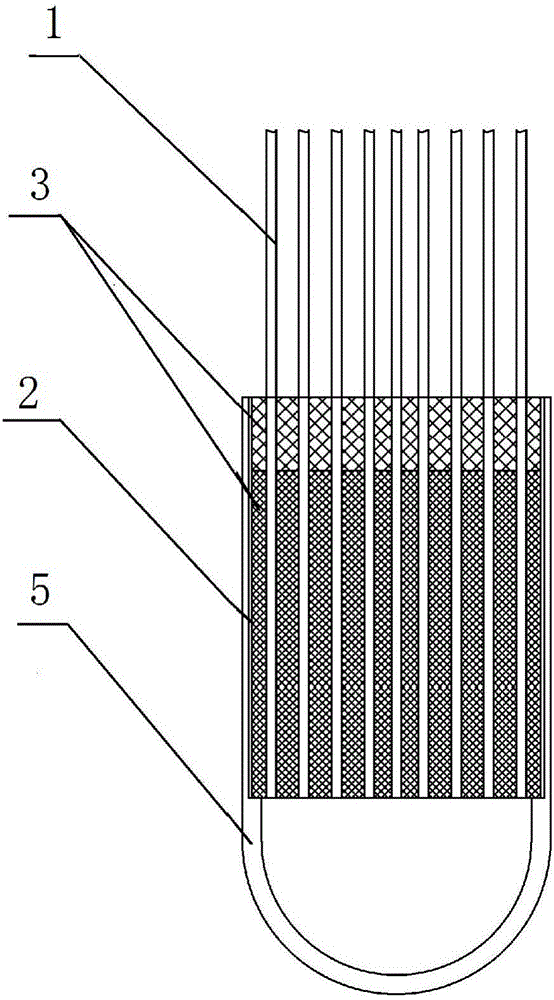

[0040] refer to figure 1 and figure 2 , the hollow fiber curtain membrane element sealing method of the present invention comprises: hollow fiber membrane tow 1, box body 2, sealant 3, glue reservoir 4, membrane box 5 and hose 6, and the method comprises the following steps:

[0041] (1) bundling several hollow fiber membranes into bundles to form hollow fiber membrane bundles 1;

[0042] (2) bundling the bottom of the hollow fiber membrane tow 1 and cutting it flat;

[0043] (3) Hanging the hollow fiber membrane tow 1 on the tooling;

[0044] (4) using a plugging substance to block the inner pores of the hollow fiber membranes;

[0045] (5) After the above-mentioned plugging substance is solidified, place the box body 2 horizontally on the tooling, insert the hollow fiber membrane tow 1 into the bottom of the box body 2, and fix the hollow fiber membrane tow 1;

[0046] (6) inject the sealant 3 into the box body 2, so that the sealant 3 fills the space between the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com