Gas-liquid conversion system and equipment with same

A gas-liquid and liquid technology, applied in the field of gas-liquid conversion system and equipment with the system, can solve the problems of inability to separate organic solvent and water completely, without considering the problem of process pollution, unsatisfactory recovery effect, etc., and achieve good separation standard, improve resource utilization, and make full use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

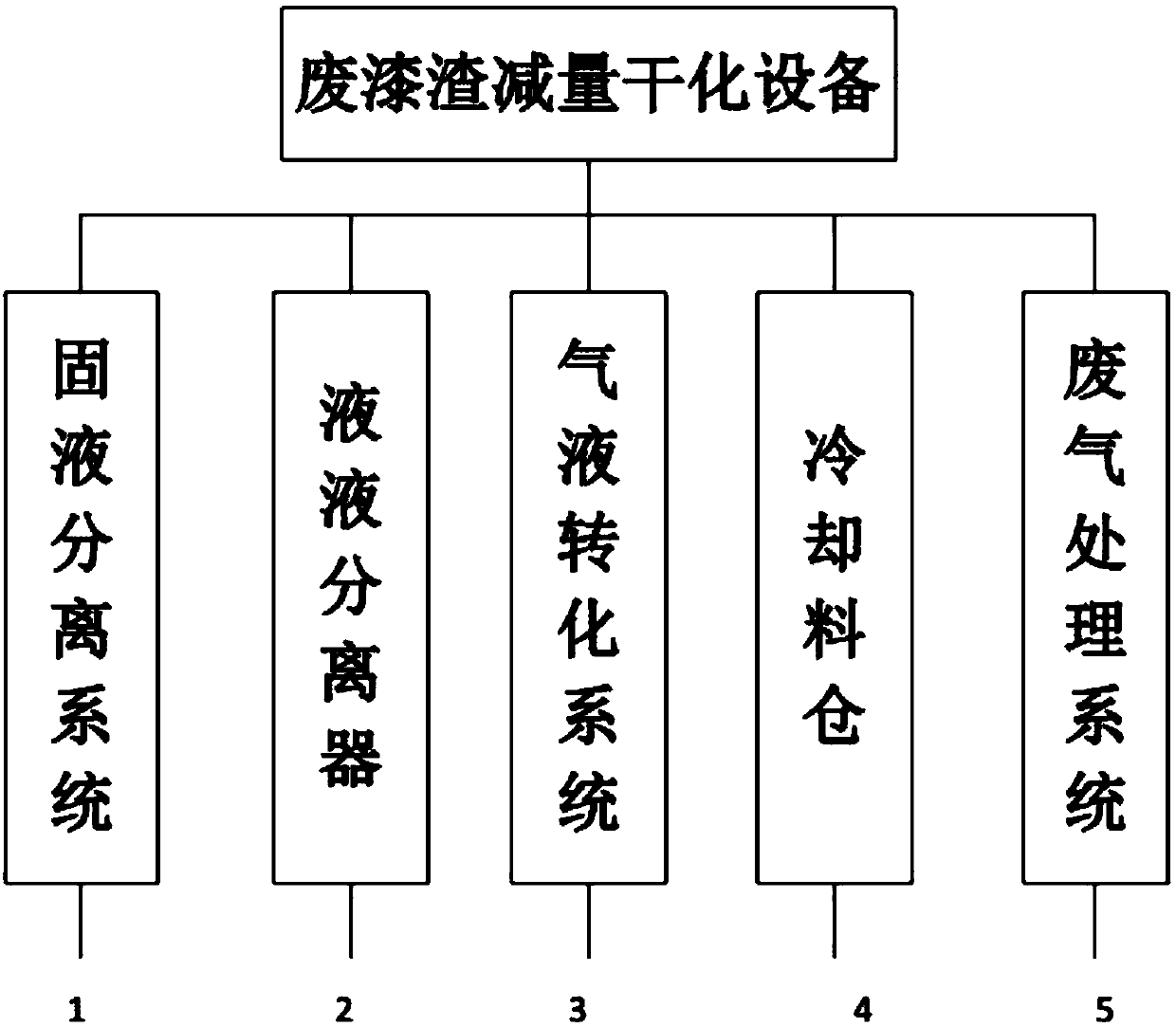

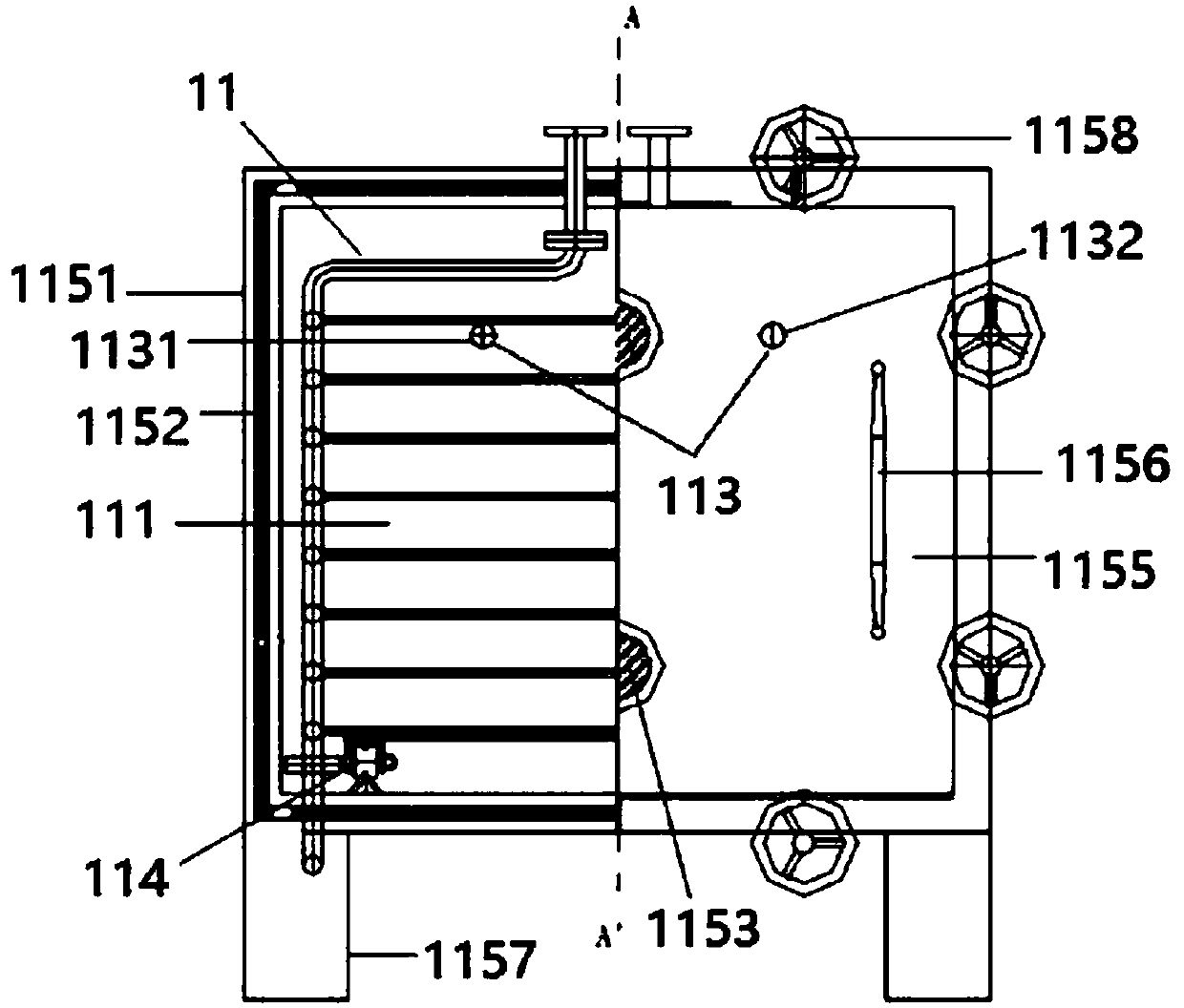

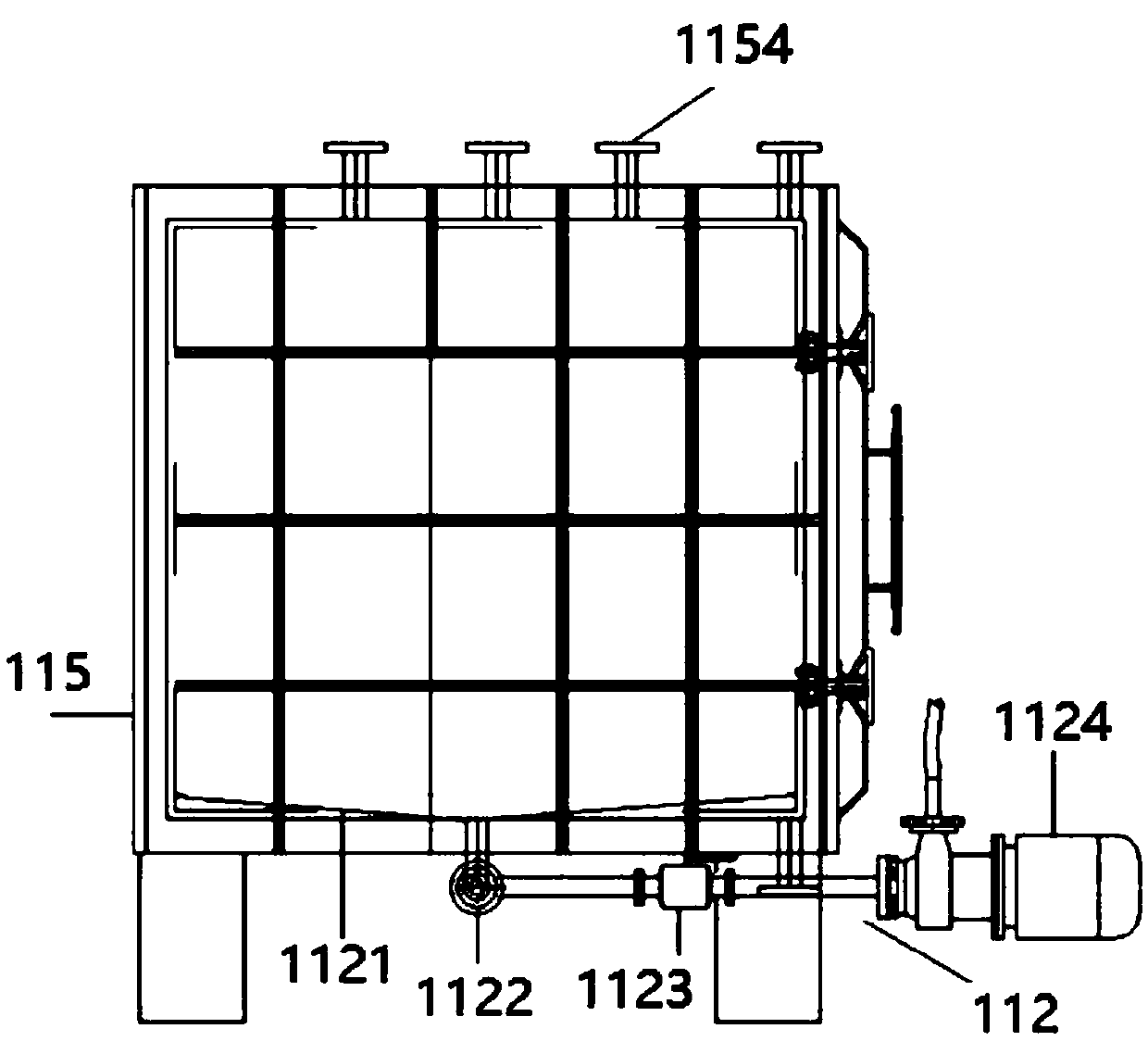

[0046] like figure 1 As shown, a waste paint slag reduction and drying equipment includes: a solid-liquid separation system 1 , a liquid-liquid separator 2 , a gas-liquid conversion system 3 , a cooling silo 4 , and a waste gas treatment system 5 .

[0047] Put the waste paint slag into the solid-liquid separation system 1, dry it under negative pressure, extract the water vapor, sewage, and organic solvent generated during the drying process, and realize solid-liquid separation; dry the waste paint slag after a certain period of time sent to the cooling silo 4 for cooling treatment; the extracted sewage and organic solvent enter the liquid-liquid separator 2 for separation, the organic solvent can be recycled after being stored in the storage box, and the sewage enters the sewage treatment system for treatment and discharge after reaching the standard; The exhausted gas enters the gas-liquid conversion system 3 for treatment, the separated waste gas is discharged up to the st...

Embodiment 2

[0099] like Figure 18 As shown, the present invention provides a kind of waste paint slag reduction drying process, comprising the following steps:

[0100] In the first step, the waste paint slag is put into the drying host in the solid-liquid separation system 1 for drying, and the drying host is set as a negative pressure environment;

[0101] In the second step, the water vapor and organic solvent generated in the solid-liquid separation system 1 are cooled by the refrigerating unit 34 to realize gas-liquid conversion;

[0102] In the third step, the water vapor and organic solvent are pumped out with a vacuum pump, and the gas enters the exhaust gas treatment system 5, and is discharged after the treatment reaches the standard, and the organic solvent is recycled;

[0103] In the fourth step, the liquid obtained from the solid-liquid separation system 1 and the gas-liquid conversion system 2 is sewage and organic solvent, and the organic solvent is recycled through the ...

Embodiment 3

[0107] The difference between this embodiment and the above-mentioned embodiment is that the thermometer of a device for reducing and drying waste paint slag can use a glass rod thermometer or a platinum thermal resistance sheet. Because the movement of gas molecules is very inactive under vacuum conditions, ordinary thermometers cannot display the real temperature of waste paint residue, but can only indicate the relative temperature of waste paint residue. The position indicated by the mercury column of the left-point thermometer does not decrease with the decrease of temperature, but remains and indicates the highest point ever reached; platinum thermal resistance elements usually use industrial mica platinum resistance as the temperature measurement sensor, and the temperature transmitter , regulators and display instruments are used together to form a process control system, which can be used to directly measure or control the temperature of liquid, steam and gas media and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com