Sodium sulfate wastewater treatment process

A treatment process, sodium sulfate technology, applied in heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the pressure of increasing treatment cost and environment, high energy consumption cost, Deal with problems such as high cost, and achieve the effects of low power of supporting power equipment, reduced processing cost, and high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

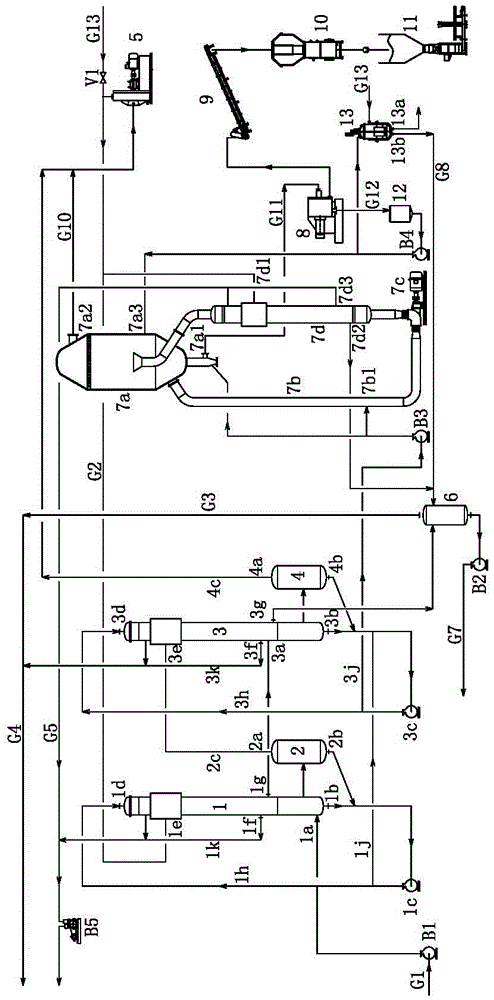

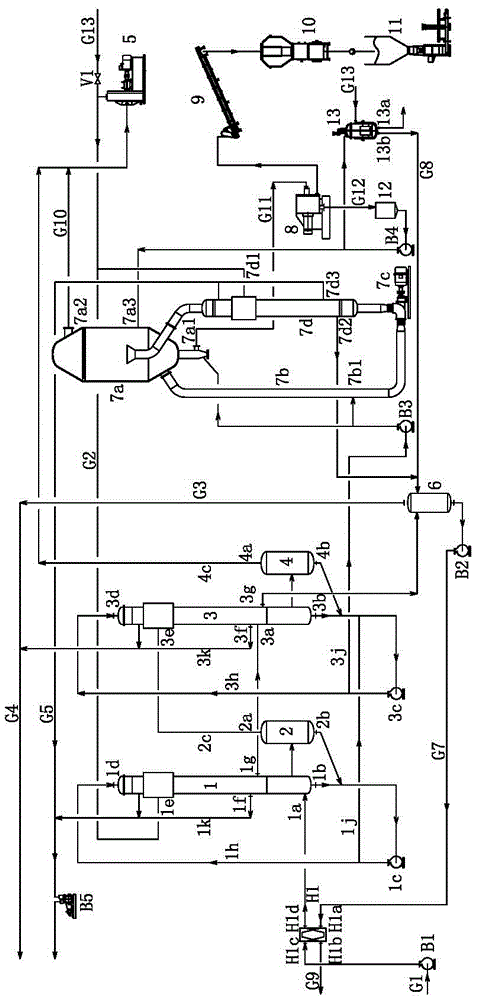

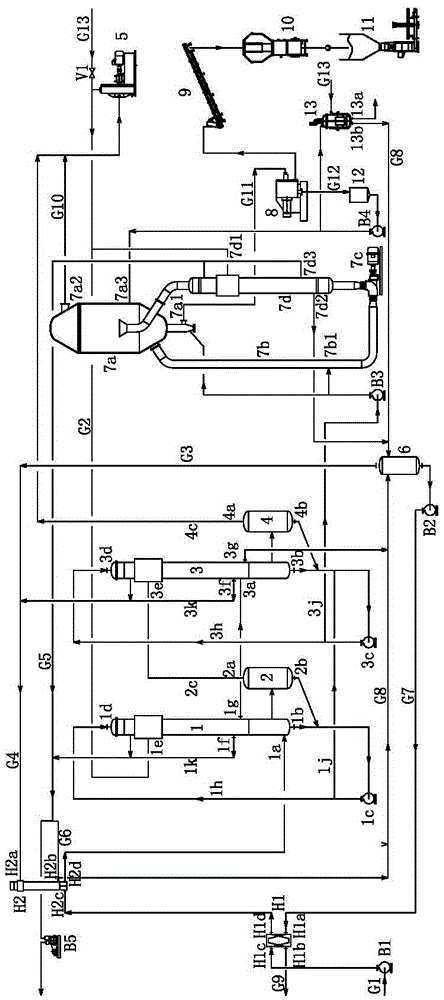

[0025] Such as Figure 1 to Figure 4 Shown, the processing technology of a kind of sodium sulfate waste water of the present invention, comprises the following steps successively: (1) new sodium sulfate waste water enters preheating unit and carries out preheating temperature rise; (2) sodium sulfate waste water after preheating enters an effect falling film evaporator 1 3. The above-mentioned one-effect concentrated solution enters the second-effect falling film evaporator 3 for further heating, evaporation and concentration to become a second-effect concentrated solution; (4) the above-mentioned second-effect concentrated solution is fed by the transfer pump B3 Send it into the forced circulation evaporation crystallizer for heating and evaporation crystallization, and the crystal slurry containing sodium sulfate crystals is discharged from the salt leg at the bottom of the evaporation chamber 7a of the forced circulation evaporation crystallizer; (5) The crystal slurry conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com