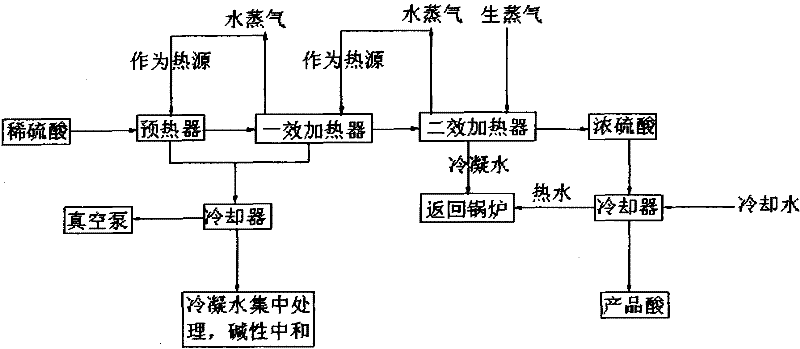

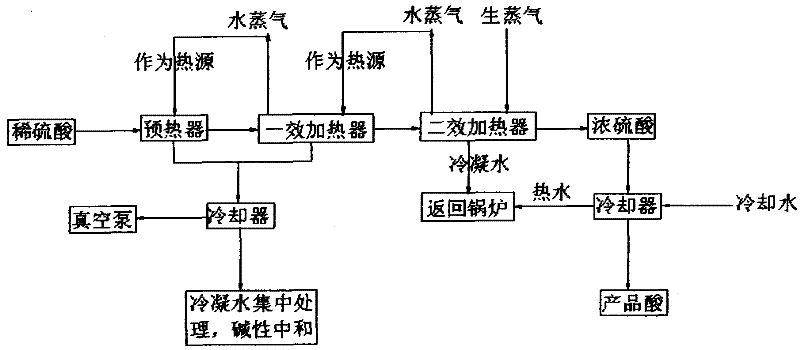

Technology for concentrating dilute sulfuric acid with multi-effect evaporation

A technology of multi-effect evaporation and dilute sulfuric acid, which is applied in the field of multi-effect evaporation and concentration of dilute sulfuric acid, can solve the problems of environmental pollution, high energy consumption for sulfuric acid concentration, and reduction of sulfuric acid concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] For example, 10 tons / hour of 30% sulfuric acid is concentrated to 70% sulfuric acid. The 30% sulfuric acid can be concentrated to about 40% in the first effect heater, and then further concentrated to 70% by the second effect. Heating to above 140 degrees Celsius, and the vacuum degree of the second effect is below -0.08MPa. The steam consumption of the second effect is about 3.2 tons / hour, and about 3 tons / hour of secondary steam is generated as the heat source of the first effect, so that the evaporation capacity of the first effect is 2.7 tons / hour, and the generated secondary steam of about 2.2 tons / hour is used as The heat source of the preheater heats the raw material to above 100 degrees Celsius. Considering the entrainment loss of materials, the final product acid yield is about 95%, and 4 tons / hour of 70% sulfuric acid can be obtained. The acid is cooled with water at 20 degrees Celsius through a cooler to obtain a product acid at about 35 degrees Celsius. S...

Embodiment 2

[0016] For example, 50 tons / hour of 25% sulfuric acid is concentrated to 70% sulfuric acid. The 25% sulfuric acid can be concentrated to about 39% in the first effect heater, and then further concentrated to 70% by the second effect. Heating to above 140 degrees Celsius, and the vacuum degree of the second effect is below -0.08MPa. The steam consumption of the second effect is about 19 tons / hour, and about 18 tons / hour of secondary steam is generated as the heat source of the first effect, so that the evaporation capacity of the first effect is 17 tons / hour, and the generated secondary steam of about 14 tons / hour is used as the heat source of the first effect. The heat source of the preheater heats the raw material to above 100 degrees Celsius. Considering the entrainment loss of materials, the final product acid yield is about 95%, and 17 tons / hour of 70% sulfuric acid can be obtained. The acid is cooled with water at 20 degrees Celsius through a cooler to obtain a product ...

Embodiment 3

[0018] For example, if 50 tons / hour of 20% sulfuric acid is concentrated to 70% sulfuric acid, the 25% sulfuric acid can be concentrated to about 31% in the first effect heater, and then further concentrated to 70% by the second effect, and the raw steam gauge pressure of the second effect At about 0.5Mpa, the temperature is close to 160°C, the material is heated to above 140°C in the second effect, and the vacuum degree of the second effect is below -0.08MPa. The steam consumption of the second effect is about 20 tons / hour, and about 18.7 tons / hour of secondary steam is generated as the heat source of the first effect, so that the evaporation capacity of the first effect is 17.5 tons / hour, and about 17 tons / hour of secondary steam is generated as The heat source of the preheater heats the raw material to above 100 degrees Celsius. Considering the entrainment loss of materials, the final product acid yield is about 95%, and 13.5 tons / hour of 70% sulfuric acid can be obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com