Oil-containing sludge disposal method

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as sedimentation blockage, damage to tower top equipment, and bumping, etc. To achieve the effect of reducing flow and power, reducing the area of heat exchanger, and preventing the phenomenon of bumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

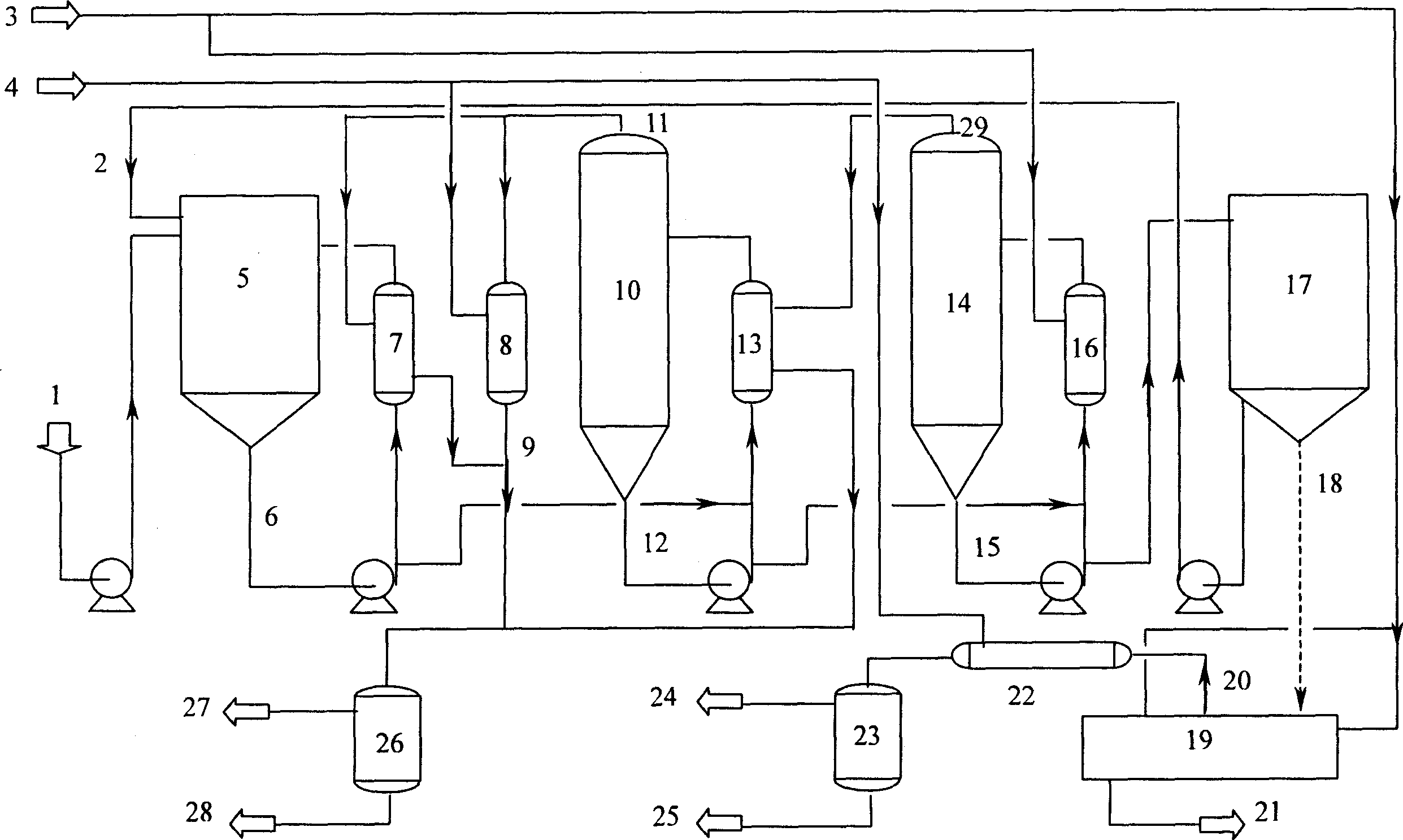

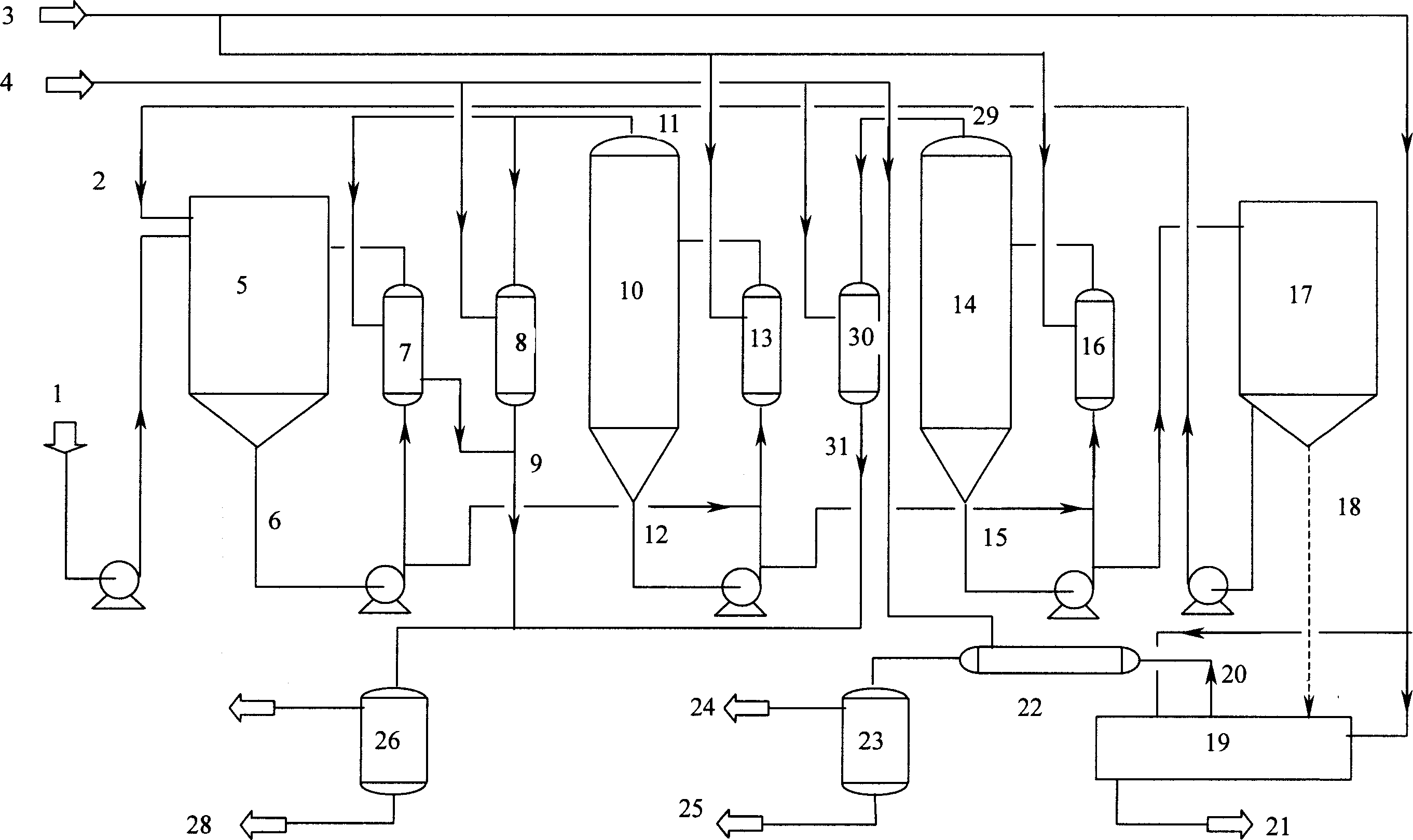

[0042] The flotation tank scum of a refinery contains a large amount of water. After dosing and centrifugal dehydration, the water content is 82.2wt%, the solid content is 3.5wt%, and the oil content is 14.3wt%. The sludge is mixed with the waste oil recovered from the sewage field (boiling point range is 150°C to 450°C) at a weight ratio of 1:2.5. The specific process flow is shown in Figure 1, and the specific operating conditions are shown in Table 1. After treatment, the final form powdery solid. The solid has good flammability and a calorific value of 3110 Cal / g. The COD in the extracted water is 180mg / L, and the oil is 32mg / L.

Embodiment 2

[0044] Compared with Example 1, the mixing method of solvent oil and sludge is mechanical stirring and preheating, without forced circulation; the calorific value of the obtained solid is 4325Cal / g. The COD in the extracted water is 160mg / L, and the oil is 41mg / L.

Embodiment 3

[0046] Compared with Example 1, the extraction evaporation system does not use forced circulation. The calorific value of the obtained solid was 3275 Cal / g. The COD in the extracted water is 210mg / L, and the oil is 55mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com