A kind of preparation method of high solid content ether type slump-retaining polycarboxylate water reducer

A high-solid content, slump-preserving technology, applied in the field of concrete admixtures, can solve the problems of a large concentration range of high-concentration polycarboxylate superplasticizers, difficult installation of a stirring device, and difficult control of safety issues, etc. Good degree of retention performance, no formaldehyde content, the effect of reducing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

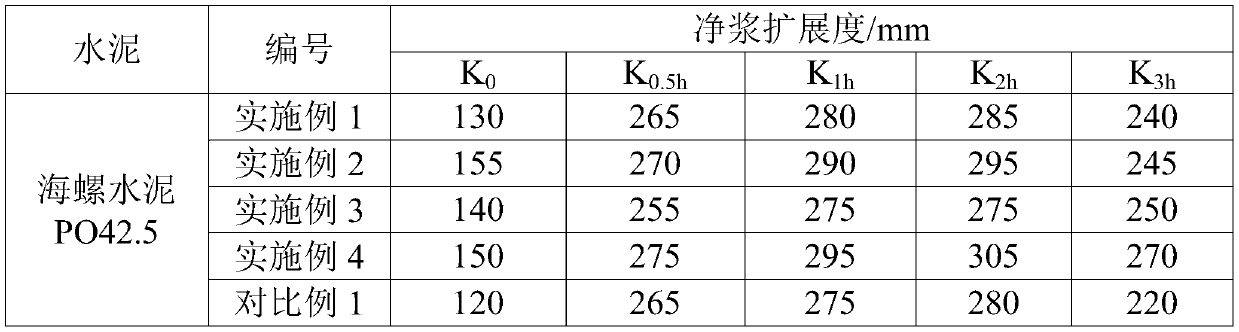

Examples

Embodiment 1

[0034] A preparation method of high solid content ether type slump-retaining polycarboxylate water reducer, comprising the following steps:

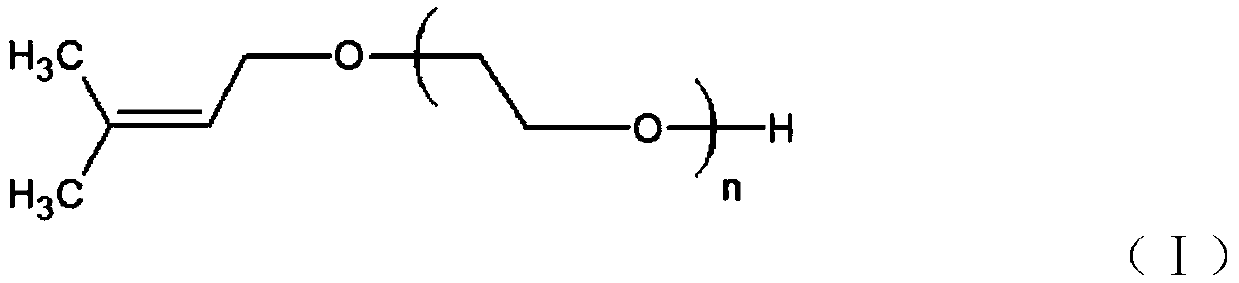

[0035](1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 100g of distilled water into a 2000mL four-necked glass flask, turn on the mixer, stir at a speed of 240r / min, and heat it to 70°C with an electric heating mantle until the bottom material Dissolved into a homogeneous transparent solution;

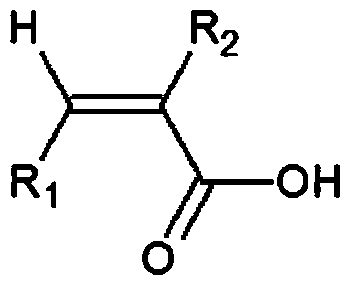

[0036] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 30°C with an ice-water bath, add 14.5g of chain transfer agent solution to the bottom of the kettle, a mixed solution prepared by 4.5g of sodium hypophosphite and 10g of water; Add 13.2g of initiator A solution to the bottom of the kettle, a mixed solution prepared from 3.2g of ammonium persulfate and 10g of water; after stirring for 5min, add dropwise monomer solution for 3h and initiator B solution for 3.5h; whe...

Embodiment 2

[0038] A preparation method of high solid content ether type slump-retaining polycarboxylate water reducer, comprising the following steps:

[0039] (1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 3000 and 100g of distilled water into a 2000mL four-neck glass flask, turn on the mixer, stir at a speed of 260r / min, and heat to 65°C with an electric heating mantle until the bottom material Dissolved into a homogeneous transparent solution;

[0040] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 25°C with an ice-water bath, add 35.8g of chain transfer agent solution to the bottom of the kettle, a mixed solution prepared by 15.8g of sodium methacrylate and 20g of water; after 10 minutes , add 18g initiator solution A to the bottom of the kettle, a mixed solution prepared by 8g ammonium persulfate and 10g water; after stirring for 5min, adopt single dropwise addition, and the dropping time is 3h; Ethyl ester, ...

Embodiment 3

[0042] A preparation method of high solid content ether type slump-retaining polycarboxylate water reducer, comprising the following steps:

[0043] (1) Add 800g of isopentenol polyoxyethylene ether with a molecular weight of 2900 and 100g of distilled water into a 2000mL four-necked glass flask, turn on the mixer, stir at a speed of 200r / min, and heat it to 80°C with an electric heating mantle until the bottom material Dissolved into a homogeneous transparent solution;

[0044] (2) Take out the electric heating mantle, cool the material at the bottom of the kettle to 20°C with an ice-water bath, add 4g of chain transfer agent solution to the bottom of the kettle, the chain transfer agent solution is 4g of mercaptoethanol; after 10min, add 7.8g of initiator to the bottom of the kettle A solution, the initiator A solution is hydrogen peroxide with a concentration of 50%; after stirring for 5 minutes, simultaneously drop the monomer solution for 3 hours, and the initiator B solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com