Medium-low temperature gel based on cationic cross-linking agent and used for stratum plugging

A cationic, low-temperature gel technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unfavorable time control, poor resistance to mineralization, prolonged gelation time, etc., to achieve easy Good operation, good salt resistance, good gelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

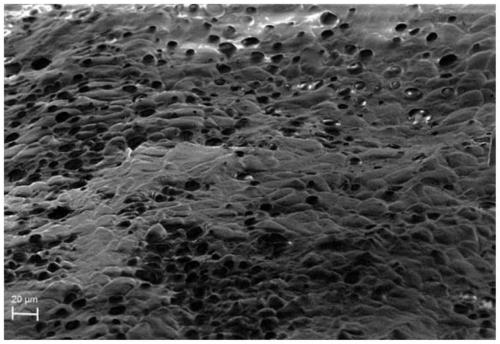

Image

Examples

Embodiment 1

[0026] In this embodiment, the preparation method of the medium and low temperature gel for formation plugging comprises the following steps:

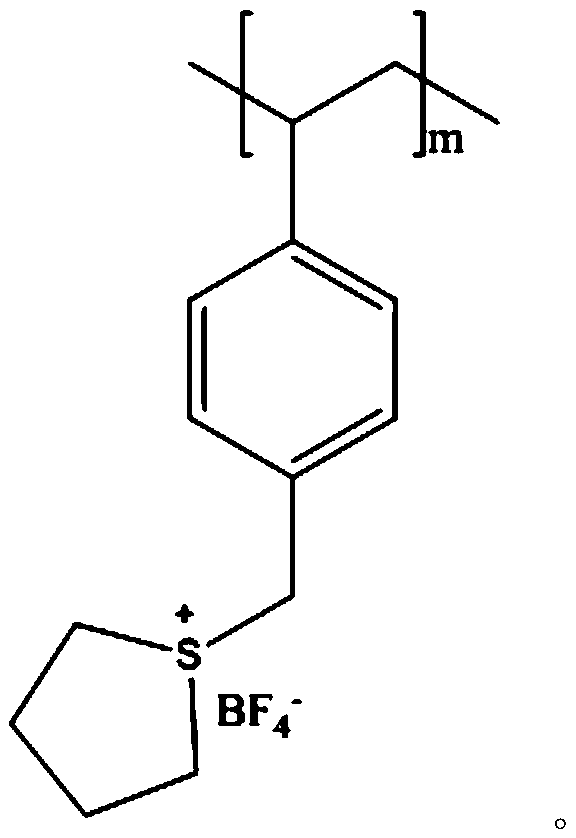

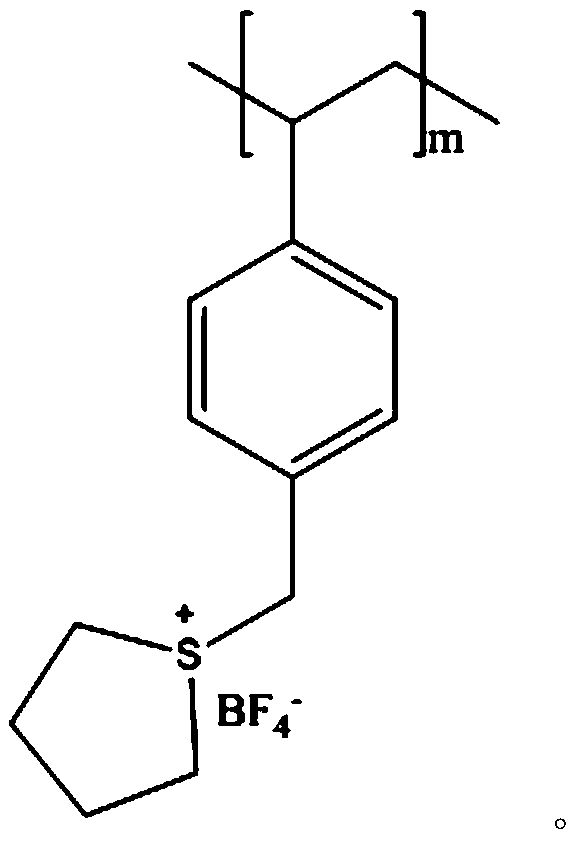

[0027] Step 1. Synthesis of cationic crosslinking agent-poly(4-vinylbenzenetetrahydrothiophene tetrafluoroborate)

[0028] S1: Add 0.25mol 4-vinylbenzyl chloride and 0.24mol tetrahydrothiophene to methanol, keep stirring in a dark environment for 4 days, remove methanol by vacuum distillation, wash with a large amount of acetone for 3 times and dry , to obtain a light yellow powdery solid, dissolve the solid in 40g of water, add 0.50mol sodium tetrafluoroborate, stir at room temperature for 1 hour, then filter to obtain a precipitate, wash the precipitate with a small amount of cold water and 250mL ether, and dry to obtain White powdery solid particles, that is, 4-vinylbenzenetetrahydrothiophene tetrafluoroborate;

[0029] S2: Weigh 0.20mol of 4-vinylbenzenetetrahydrothiophene tetrafluoroborate, dissolve it in 300mL of dimethylformami...

Embodiment 2

[0039] In this embodiment, the preparation method of the medium and low temperature gel for formation plugging comprises the following steps:

[0040] Step 1. Synthesis of cationic crosslinking agent-poly(4-vinylbenzenetetrahydrothiophene tetrafluoroborate)

[0041]S1: Add 2.5mol 4-vinylbenzyl chloride and 1.0mol tetrahydrothiophene to methanol, keep stirring in a dark environment for 4 days, remove methanol by vacuum distillation, wash with a large amount of acetone 3 times and dry , to obtain a light yellow powdery solid, dissolve the solid in 30g of water, add 2mol sodium tetrafluoroborate, stir at room temperature for 1.5 hours, then filter to obtain a precipitate, wash the precipitate with a small amount of cold water and 1000mL ether, and dry to obtain a white Powdered solid particles, that is, 4-vinylbenzenetetrahydrothiophene tetrafluoroborate;

[0042] S2: Weigh 2mol of 4-vinylbenzenetetrahydrothiophene tetrafluoroborate, dissolve it in 300mL of dimethylformamide, an...

Embodiment 3

[0046] In this embodiment, the preparation method of the medium and low temperature gel for formation plugging comprises the following steps:

[0047] Step 1. Synthesis of cationic crosslinking agent-poly(4-vinylbenzenetetrahydrothiophene tetrafluoroborate)

[0048] S1: Add 0.06mol 4-vinylbenzyl chloride and 0.06mol tetrahydrothiophene to methanol, keep stirring in a dark environment for 4 days, remove methanol by vacuum distillation, wash with a large amount of acetone 3 times and dry , to obtain a light yellow powdery solid, dissolve the solid in 20g of water, add 0.12mol sodium tetrafluoroborate, stir at room temperature for 1 hour, then filter to obtain a precipitate, wash the precipitate with a small amount of cold water and 100mL ether, and dry to obtain White powdery solid particles, that is, 4-vinylbenzenetetrahydrothiophene tetrafluoroborate;

[0049] S2: Weigh 0.05mol 4-vinylbenzenetetrahydrothiophene tetrafluoroborate, dissolve it in 250mL dimethylformamide, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com