Compound type monomer multi-effect steam mechanical recompression evaporator

A steam machinery and composite technology, which is applied to multi-effect evaporation, vertical tube evaporator, etc., can solve the problems of large space occupation, low speed and efficiency, large steam volume, etc., and achieves small space occupation, simple structure and economical efficiency. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

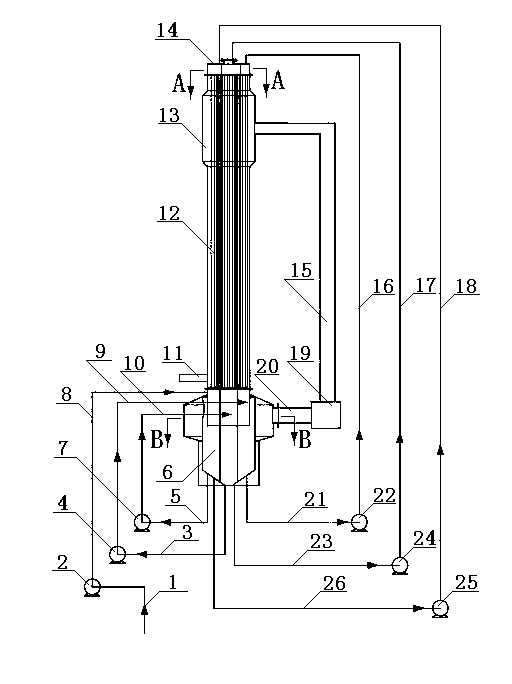

[0017] Below in conjunction with accompanying drawing, the present invention will be further described.

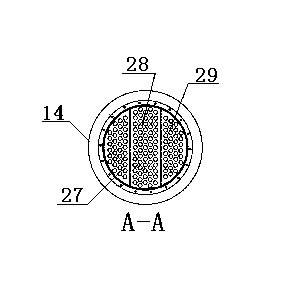

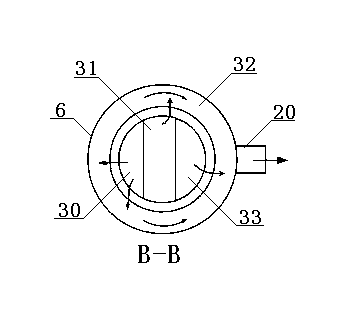

[0018] figure 1 Shown is the structural representation of the present invention. As can be seen from the figure, taking a composite single-unit multi-effect steam-mechanical recompression evaporator with a single-unit three-effect structure as an example, it is mainly composed of a distributor 14, a heater 13 and a steam-water separation chamber 6 that are sequentially connected and connected from top to bottom. The fixed connection constitutes an integral body, and there are three feed pumps 2, 4, 7 and circulation pumps 22, 24, 25 respectively. The steam mechanical compression pump 19 communicates the steam-water separation chamber 6 with the heater 13 through the steam output pipe 20 and the steam pipe 15. The material input end of the steam-water separation chamber 6 is connected with the feed pipe 1 through the first-level feed pump 2 and the first-level feed pipe 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com