Furnace tube cleaning method

A furnace tube and cleaning technology, used in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as dust pollution of silicon wafers and graphite boats, achieve good dust reduction effect, and prevent adhesion to materials. The effect of surface, reducing the probability of black spots and pitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

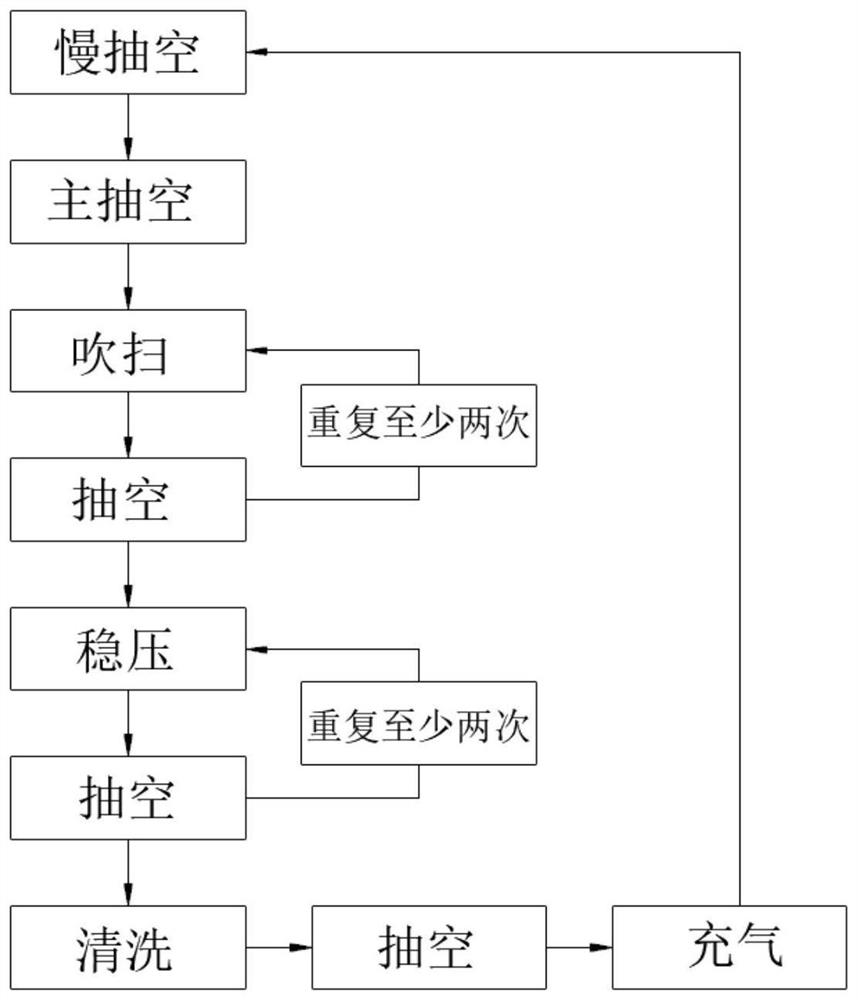

[0039] This embodiment provides a furnace tube cleaning method, the furnace tube cleaning method is as follows figure 1 shown, including the following steps:

[0040] (1) Perform slow evacuation and main evacuation in sequence in the furnace tube. The evacuation time of the slow evacuation is 120s. After the slow evacuation, the vacuum degree in the furnace tube is 1520Pa; The vacuum in the tube is 30Pa;

[0041] (2) Use nitrogen to purge the furnace tube, the nitrogen flow rate is 500sccm, and the purge temperature is 420°C; after the purge is completed, the furnace tube is evacuated, and the vacuum degree in the furnace tube is evacuated to 30Pa to complete a purge Evacuation operation; then repeat the purge and evacuation operation 3 times, the time of each purge is controlled at 200s, and the total duration of the purge during the entire purge and evacuation process is controlled at 10min;

[0042] (3) After the purging and evacuation operation cycle is completed, after ...

Embodiment 2

[0046] This embodiment provides a furnace tube cleaning method, the furnace tube cleaning method is as follows figure 1 shown, including the following steps:

[0047] (1) Perform slow evacuation and main evacuation in sequence in the furnace tube. The evacuation time of the slow evacuation is 140s. After the slow evacuation, the vacuum degree in the furnace tube is 1000Pa; The vacuum in the tube is 23Pa;

[0048] (2) Use nitrogen to purge the furnace tube, the nitrogen flow rate is 1000sccm, and the purge temperature is 450°C; after the purge is completed, the furnace tube is evacuated, and the vacuum degree in the furnace tube is evacuated to 23Pa to complete a purge Evacuation operation; then repeat the purge and evacuation operation 6 times, the time of each purge is controlled at 100s, and the total duration of the purge during the entire purge and evacuation process is controlled at 10min;

[0049] (3) After the purging and evacuation operation cycle is completed, after...

Embodiment 3

[0053] This embodiment provides a furnace tube cleaning method, the furnace tube cleaning method is as follows figure 1 shown, including the following steps:

[0054] (1) Perform slow evacuation and main evacuation in sequence in the furnace tube. The evacuation time of the slow evacuation is 160s. After the slow evacuation, the vacuum degree in the furnace tube is 800Pa; The vacuum in the tube is 20Pa;

[0055] (2) Use nitrogen to purge the furnace tube, the nitrogen flow rate is 1600sccm, and the purge temperature is 500°C; after the purge is completed, the furnace tube is evacuated, and the vacuum degree in the furnace tube is evacuated to 20Pa to complete a purge Evacuation operation; then repeat the purge and evacuation operation 6 times, the time of each purge is controlled at 120s, and the total duration of the purge during the entire purge and evacuation process is controlled at 12min;

[0056] (3) After the purging and evacuation operation cycle is completed, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com