Construction fence and dust control method

A technology for construction of enclosures and baffles, applied in separation methods, chemical instruments and methods, fences, etc., can solve the problems of affecting the surrounding air quality, harsh construction environment, waste of water resources, etc., to achieve efficient dust reduction operations and improve construction. The effect of environment and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

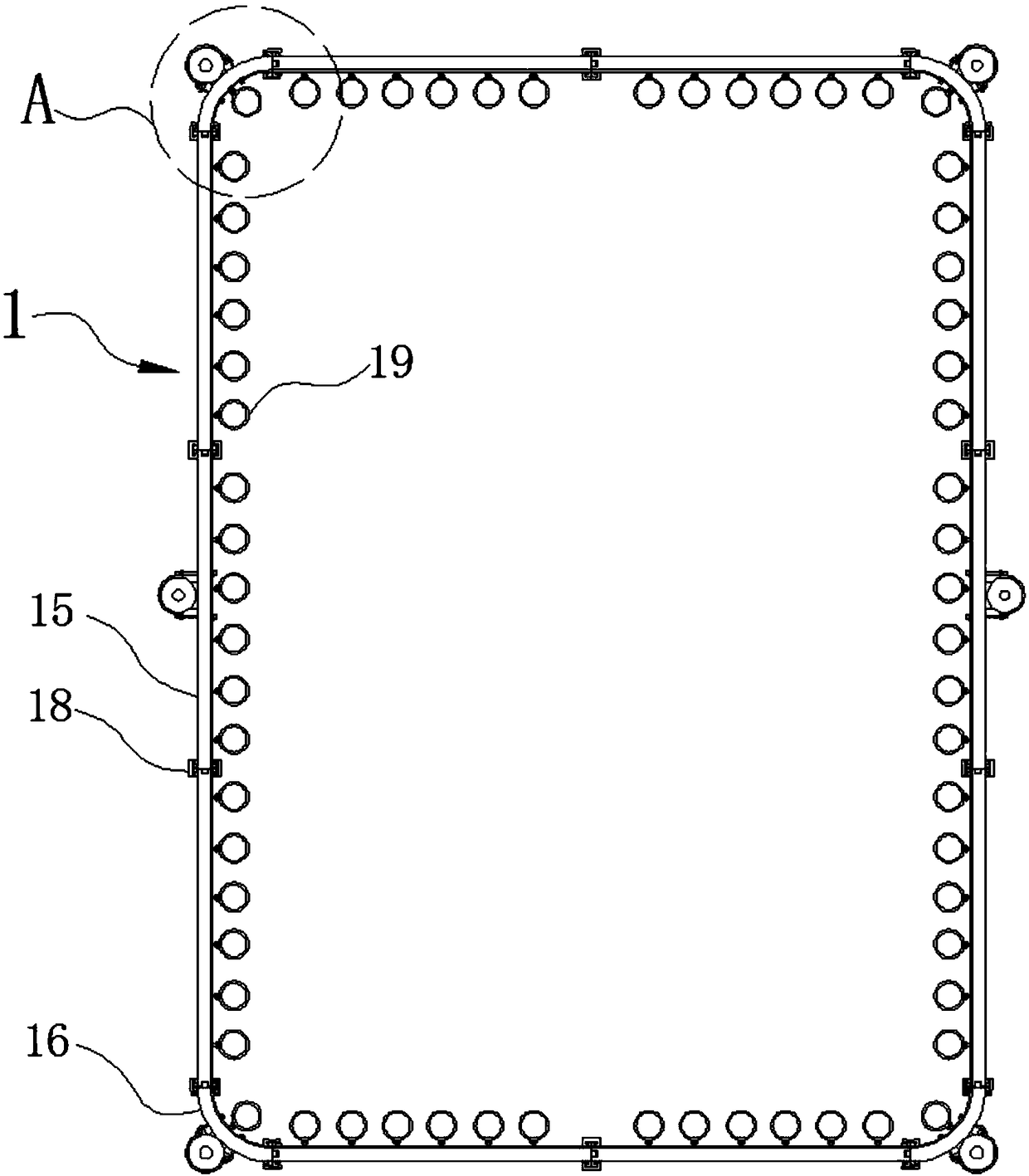

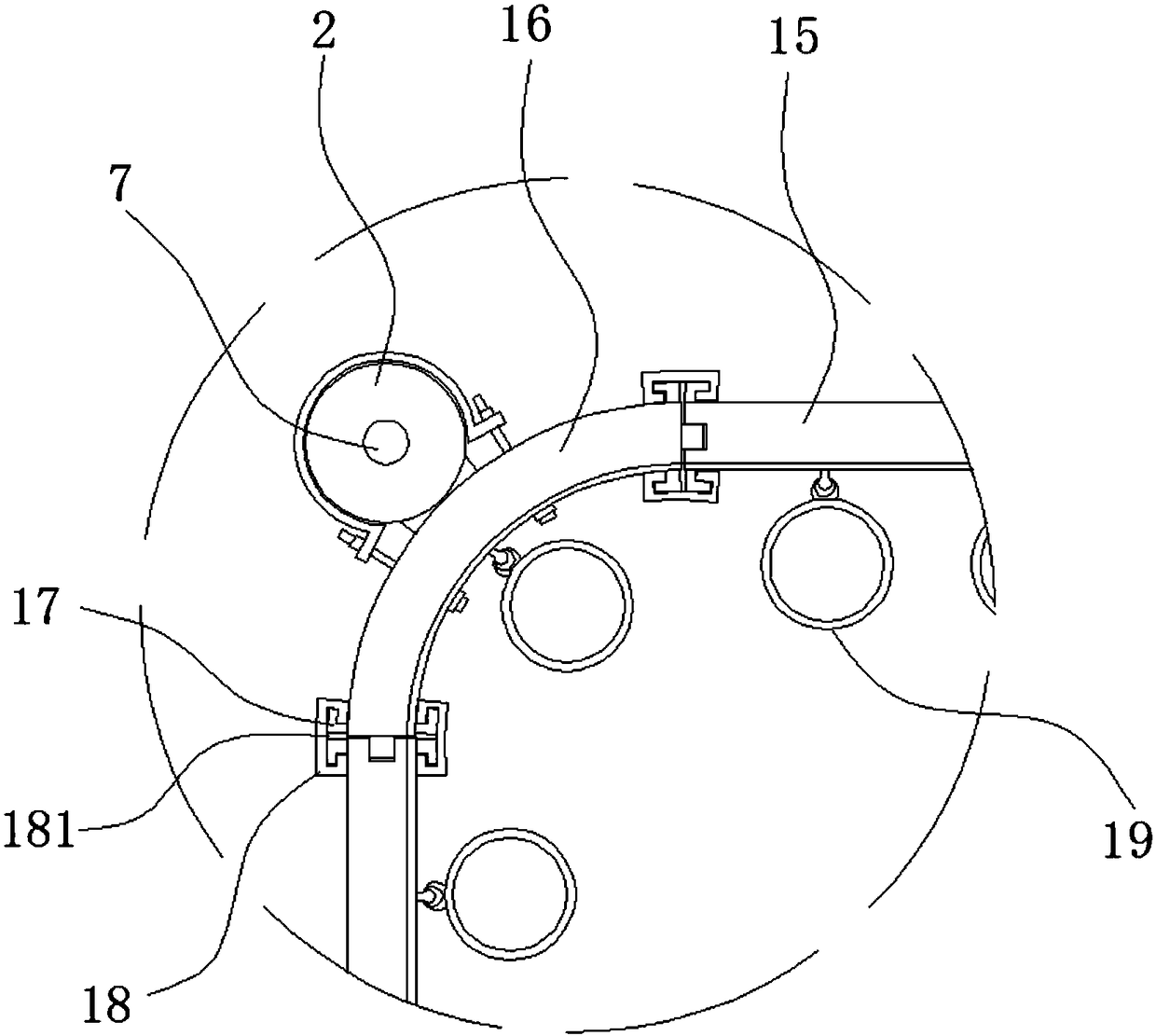

[0043] see Figure 1 to Figure 6 , a construction enclosure, comprising:

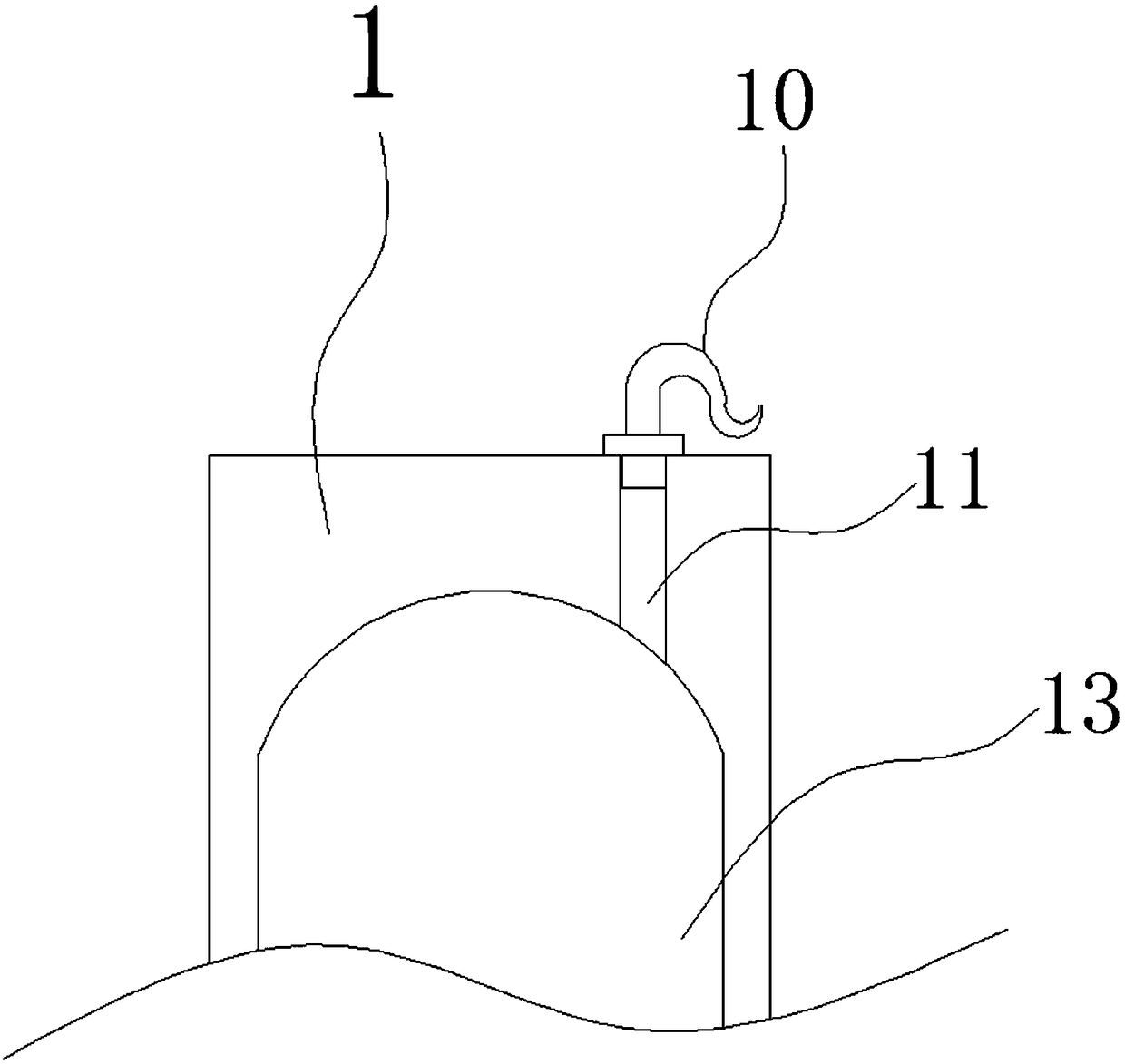

[0044] Blocking body 1, the blocking body 1 is a vertical plate shape and connected end to end to form an enclosed shape, the upper half of the blocking body 1 is hollow to form a hollow part 13, and the lower half is solid to form a structural support body 14; the blocking body 1. Along the length direction of the baffle body 1, there are first slits 11 connecting the hollow part 13 for air outlet; the first slits 11 are connected end to end; air through slit 12;

[0045] A plurality of hollow columns 2, the hollow columns 2 are arranged on the outside surrounded by the block body 1 and are fixedly connected with the block body 1, the bottom ends of the hollow columns 2 are fixed on the ground, and the upper ends are closed; the upper side of the hollow columns 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com