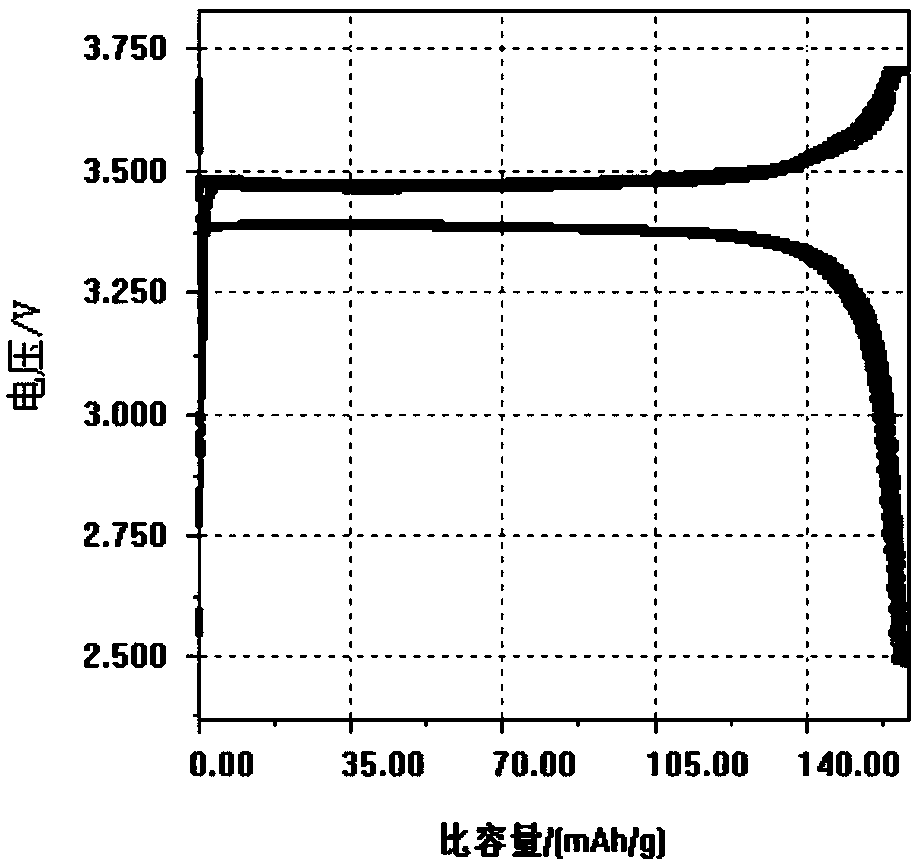

Lithium iron phosphate-based composite material with capacity higher than theoretical capacity of lithium iron phosphate, preparation method and use of lithium iron phosphate-based composite material

A composite material, lithium iron phosphate technology, applied in final product manufacturing, sustainable manufacturing/processing, electrolyte battery manufacturing, etc., can solve problems such as low surface electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] (1) Add 1g of cetyltrimethylammonium bromide to 1L of deionized water and stir evenly, add 0.001mol carbon nanowires to the above solution at a stirring speed of 400r / min, and wait for the carbon nanowires to disperse evenly , add ferrous chloride, ammonium dihydrogen phosphate successively wherein according to the ratio of molar ratio Fe:P=1:1.03, make the overall molar concentration of final solution with Fe 2+ Calculated as 0.1mol / L.

[0084] (2) Stir the obtained solution evenly, and add ammonia solution to it under stirring condition until the pH of the solution is about 7. The obtained solution was transferred into a reaction kettle, and reacted in a sealed manner at 100° C. for 24 hours, and the obtained precipitate was filtered, washed and dried to obtain a composite precursor material.

[0085] (3) Lithium carbonate, composite precursor material, and ammonium dihydrogen phosphate are sequentially added to the mixer at a molar ratio Li:Fe:P=3:3:1 and mixed and ...

Embodiment 2

[0095] (1) Add 2g polyvinyl alcohol to 1L deionized water and stir evenly, add 0.005mol carbon nanotubes to the above solution at a stirring speed of 400r / min, after the carbon nanotubes are uniformly dispersed, the molar ratio of Fe: The ratio of P=1:1.01 adds ferrous oxalate and diammonium hydrogen phosphate to it successively, so that the overall molar concentration of the final solution is expressed as Fe 2+ Calculated as 0.2mol / L.

[0096] (2) Stir the obtained solution evenly, and add ammonia solution to it under stirring conditions until the pH of the solution is about 7; transfer the obtained solution into a reaction kettle, and react in a sealed manner at 180° C. for 18 hours; filter the obtained precipitate, wash, Dry to obtain a composite precursor material.

[0097] (3) According to the molar ratio Li:Fe:P=3.15:3:1.03, add lithium acetate, composite precursor material, and diammonium hydrogen phosphate to the mixer in sequence and mix and stir for 4 hours, and put...

Embodiment 3

[0102] (1) Add 5g polyethylene glycol to 1L deionized water and stir evenly, add 0.04mol graphene to the above solution at a stirring speed of 400r / min, after the carbon nanowires are uniformly dispersed, the molar ratio of Fe: The ratio of P=1:1.02 adds ferrous sulfate, ammonium phosphate to it successively, makes the integral molar concentration of final solution to be Fe 2+ Calculated as 0.5mol / L.

[0103] (2) Stir the obtained solution evenly, and slowly add ammonia solution to it under stirring condition until the pH of the solution is about 4. The obtained solution was transferred into a reaction kettle, and the closed reaction was carried out at 150° C. for 20 h, and the obtained precipitate was filtered, washed and dried to obtain a composite precursor material.

[0104] (3) According to the molar ratio Li:Fe:P=3.13:3:1, add lithium chloride, composite precursor material, and phosphoric acid to the mixer in sequence and mix and stir for 6 hours, and place the resultin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com