High-vacuum die-casting production process of rear rocker arm of motorcycle

A production process, the technology of the rear rocker arm, which is applied in the manufacture of motorcycle parts and the field of steam, can solve the problems of inability to carry out heat treatment and welding, difficulty in controlling welding deformation, and large amount of machining, so as to achieve easy automation, reduce machining allowance, and reduce material The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

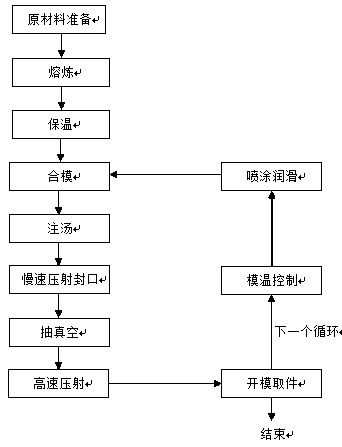

[0038] Embodiment 1: A kind of high-vacuum die-casting production process of motorcycle rear rocker arm, comprises the following steps:

[0039] 1) Melting: AlSi 10 MgMn is melted at 730°C, and the proportion of returned materials is 30%, and then transferred to the transfer bag. When the temperature of the molten aluminum is 720°C, add a refining agent of 0.05% of the mass of the molten aluminum, and pass in argon for refining, and the degassing time is 10 minutes;

[0040] 2) Heat preservation: test the chemical composition and slag content of the molten aluminum prepared in step 1), and the density is greater than 2.6g / cm 3 , qualified can be transferred to the machine side holding furnace, holding temperature 680 ℃;

[0041] 3) Mold clamping: reset the mold ejector pin, pull the core of the movable mold in, close the mold, arrange the sealing ring between the mold ejector pin and the mold frame, arrange the sealing strip on the core-pulling slider of the movable mold, and...

Embodiment 2

[0048] Embodiment 2: a kind of high-vacuum die-casting production process of motorcycle rear rocker arm, comprises the following steps:

[0049] 1) Melting: AlSi 10 MgMn is melted at 740°C, and the proportion of returned charge is 35%, and then transferred to the transfer bag. When the temperature of the aluminum liquid is 720°C, add a refining agent of 0.1% of the mass of the aluminum liquid, and pass in argon for refining, and the degassing time is 15 minutes;

[0050] 2) Heat preservation: test the chemical composition and slag content of the molten aluminum prepared in step 1), and the density is greater than 2.6g / cm3 , qualified can be transferred to the machine side holding furnace, holding temperature 690 ℃;

[0051] 3) Mold clamping: reset the mold ejector pin, pull the core of the movable mold in, close the mold, arrange the sealing ring between the mold ejector pin and the mold frame, arrange the sealing strip on the core-pulling slider of the movable mold, and arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com