Method for forming low-porosity multi-branch heat dissipation structure through metal droplet printing

A technology of heat dissipation structure and porosity, applied in the field of dendritic radiator preparation, can solve problems such as poor practicability, inability to manufacture complex three-dimensional multi-branched special-shaped heat dissipation structures, etc., to improve thermal conductivity, improve internal quality, and optimize internal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

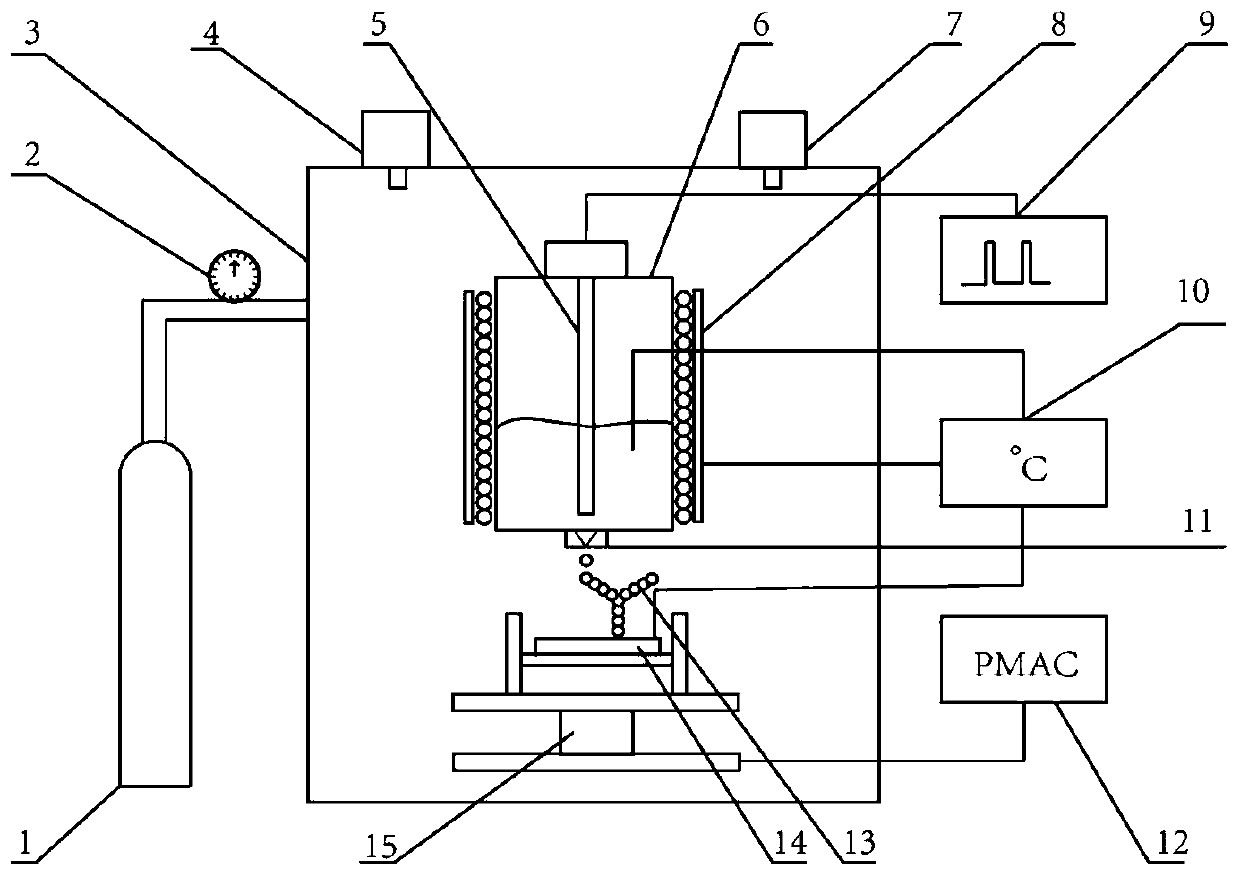

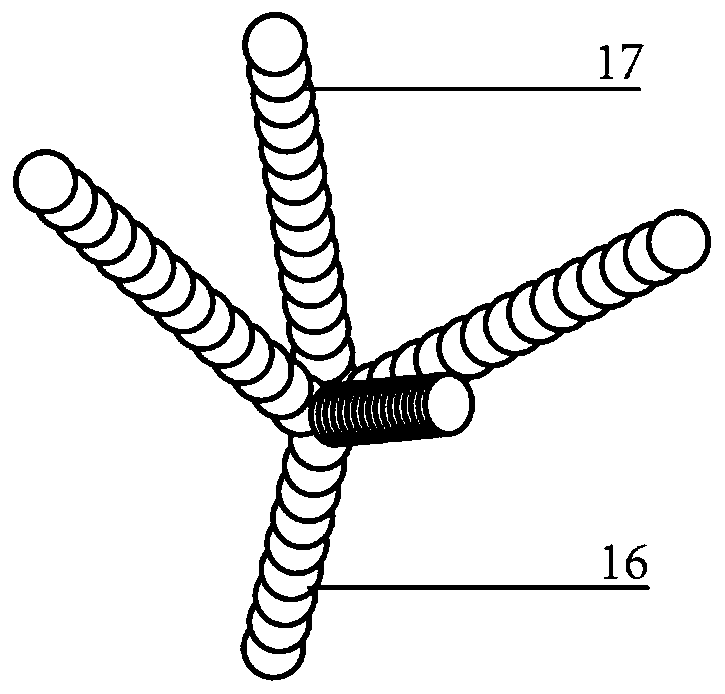

[0021] Embodiment 1: The aluminum alloy dendritic heat dissipation structural unit with four branches is formed.

[0022] An aluminum alloy branch-shaped heat dissipation structural unit with four branches is formed. The overall height of the part is 15mm and the width is 10mm.

[0023] Step 1. Open the argon cylinder 1 one hour in advance, make the argon pressure gauge 2 display 0.2Mpa, and clean the glove box 3 with argon until the oxygen content detector 4 shows below 20PPM, and the water content detector The reading of 7 is below 10PPM;

[0024] Step 2: Use 0.1mol / L NaOH solution outside the glove box to soak the aluminum alloy raw materials for 30 minutes, and then wash in nitric acid for 10 seconds to remove the oxide scale on the aluminum alloy surface;

[0025] Step 3. Put the four processed in step two into the crucible 6, and then sequentially assemble the vibration rod 5, the nozzle 11 and the crucible 6 into the heating furnace 8 in the glove box 3;

[0026] Step 4. Set the...

Embodiment 2

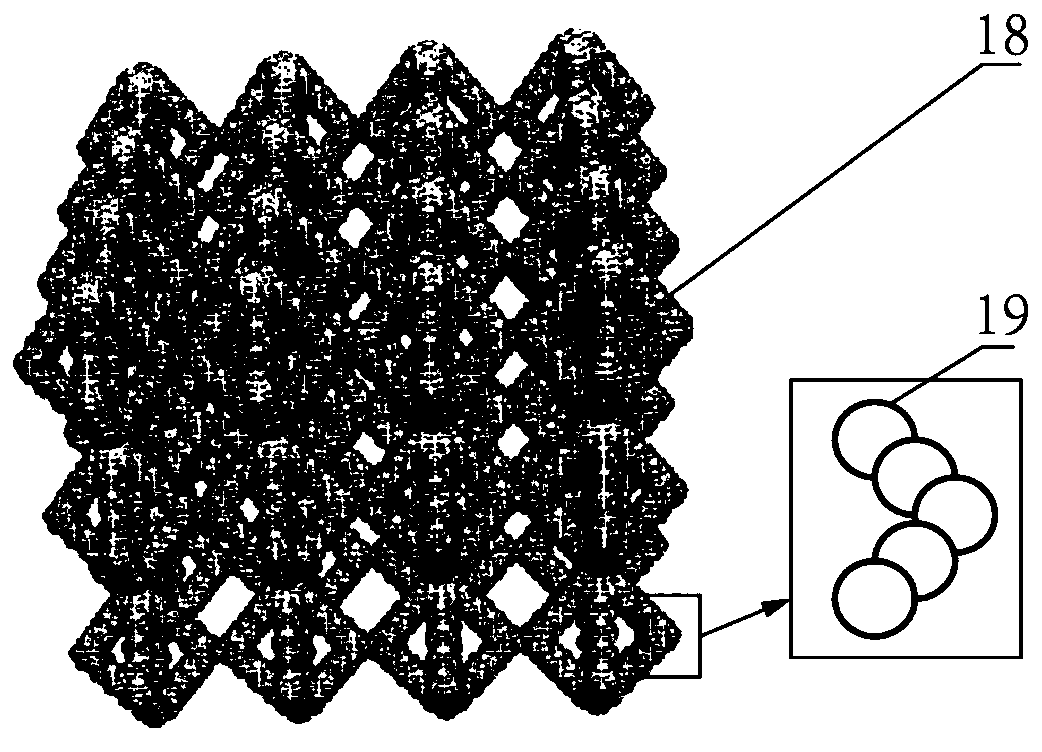

[0029] Embodiment 2: Aluminum alloy dendritic lattice array heat sink is formed.

[0030] A dendritic lattice array heat sink is formed. The overall height of the part is composed of a plurality of dendritic structural units with four branches. Compared with the first embodiment, the structure is more complicated, and the dendritic structure needs to be realized The left and right connections and stacking between the units. This embodiment is basically the same as the process of embodiment 1 when applied, and the difference is that the molding time is longer, so the requirements on the environment are higher, and the way of model path planning and printing program generation is different.

[0031] Step 1. Open the argon cylinder 1 2 hours in advance, make the indication of the argon pressure gauge 2 0.2Mpa, clean the glove box 3 with argon, make the indication of the oxygen content detector 4 below 10PPM, and the water content detector The reading of 7 is below 5PPM;

[0032] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com