Preparation method of high-strength light-weight refractory material

A light-weight refractory material and high-strength technology, applied in the field of refractory materials, can solve the problems of poor mechanical properties of light-weight refractory materials, and achieve the effects of reducing apparent porosity, dense matrix, and shrinking internal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

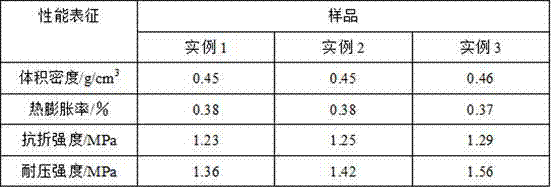

Examples

example 1

[0020] Take moso bamboo and place it in a flaker, beat it into shavings with a length of 20mm, rinse with clean water for 3 times and then dry them in a drying kiln until the water content is 5% to obtain moso bamboo shavings, collect the moso bamboo shavings and grind them Pass through a 200 mesh sieve to obtain bamboo shavings particles and count in parts by weight, weigh 45 parts of mass fraction 10% sodium hydroxide solution, 10 parts of bamboo shavings particles and 3 parts of urea in a beaker, stir and mix and place- Freeze at 15°C for 3 hours, let it stand at room temperature and filter, collect the filtrate and calculate by weight parts, weigh 45 parts of the filtrate, 1 part of ethyl acetate, 0.5 part of acetic acid and 1.0 part of chloroform In the Erlenmeyer flask, stir and mix and let it stand for solidification for 10 minutes, then collect the filtrate to obtain a gel solution; according to the mass ratio of 1:5, add peach gum powder to the gel solution, stir and m...

example 2

[0022] Take moso bamboo and place it in a flaker, beat it into shavings with a length of 20mm, rinse with clean water for 3 times and then dry them in a drying kiln until the water content is 5% to obtain moso bamboo shavings, collect the moso bamboo shavings and grind them Pass through a 200 mesh sieve to obtain bamboo shavings particles and count in parts by weight, weigh 45 parts of mass fraction 10% sodium hydroxide solution, 10 parts of bamboo shavings particles and 3 parts of urea in a beaker, stir and mix and place- Freeze at 15°C for 3 hours, let it stand at room temperature and filter, collect the filtrate and calculate by weight parts, weigh 45 parts of the filtrate, 1 part of ethyl acetate, 0.5 part of acetic acid and 1.0 part of chloroform In the Erlenmeyer flask, stir and mix and let it stand for solidification for 12min, then collect the filtrate to obtain the gel liquid; according to the mass ratio of 1:5, add the peach gum powder to the gel liquid, stir and mix ...

example 3

[0024] Take moso bamboo and place it in a flaking machine, beat it into 25mm shavings, wash it with water for 4 times and then dry it in a drying kiln until the water content is 7% to get moso bamboo shavings, collect the moso bamboo shavings and grind them Pass through a 200-mesh sieve to obtain bamboo shavings and count in parts by weight, weigh 47 parts of mass fraction 10% sodium hydroxide solution, 12 parts of bamboo shavings and 4 parts of urea in a beaker, stir and mix and place- Freeze at 12°C for 4 hours, let it stand at room temperature and filter, collect the filtrate and calculate by weight parts, weigh 47 parts of the filtrate, 2 parts of ethyl acetate, 0.7 parts of acetic acid and 1.2 parts of chloroform In the Erlenmeyer flask, stir and mix and let it stand for solidification for 12min, then collect the filtrate to obtain the gel liquid; according to the mass ratio of 1:5, add the peach gum powder to the gel liquid, stir and mix to obtain the mixed liquid and cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com